Novel combined high-speed electromagnet iron core

A high-speed electromagnet and combined technology, applied in the direction of electromagnets with armatures, electromagnets, magnetic cores/yokes, etc., can solve the problems of easily damaged bonding or welding structures, poor connection structure firmness, and low processing method efficiency and other problems, to achieve low processing cost, high processing efficiency, and avoid low processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

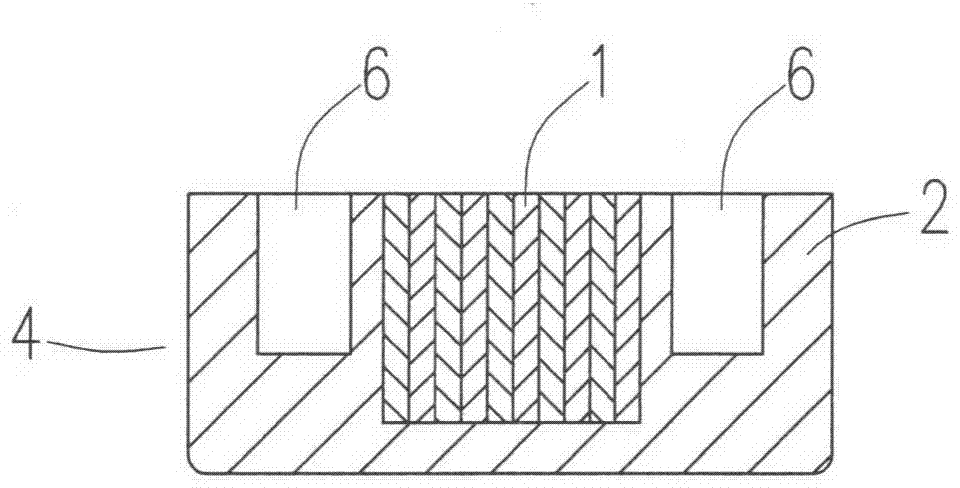

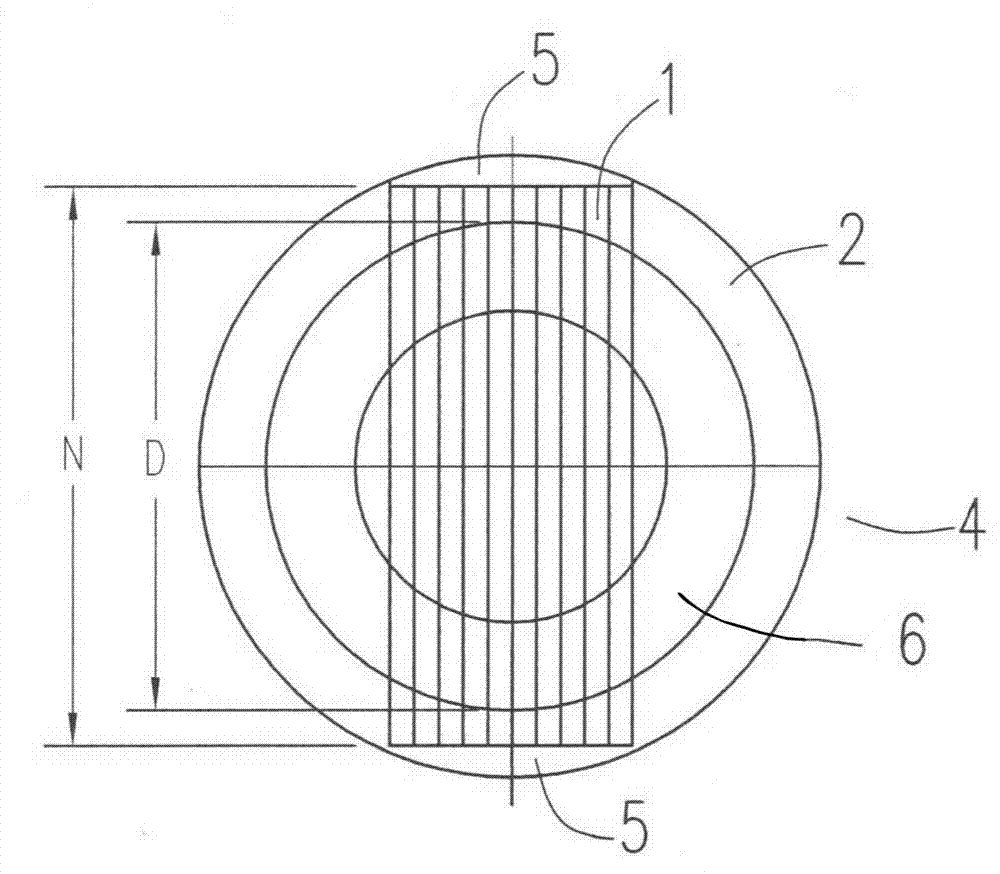

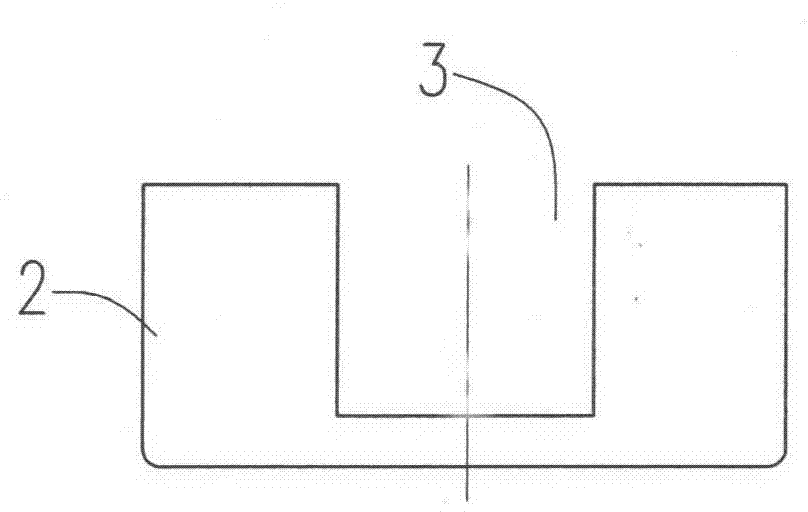

[0020] Such as Figure 1 to Figure 9 As shown, an embodiment of the present invention includes several pieces of silicon steel sheets 1 with the same length and width, and a cylindrical iron core seat 2 provided with radial through grooves 3. The several pieces of silicon steel sheets 1 are stacked and embedded in each other. The iron core assembly 4 is formed in the radial through slot 3, the length M of the silicon steel sheet 1, the length N of the radial through slot 3, and the outer diameter D of the annular coil slot 6 satisfy the following relationship: D Figure 9 It is another embodiment structure of D<M<N.

[0021] Its principle is: the present invention only has two kinds of parts assembled and processed, has saved the assembly structure of the non-magnetic metal overcoat that the prior art adopts, the length M of described silicon steel sheet 1, described radial through groove The length N of 3 and the outer diameter D of the annular coil slot 6 satisfy the followin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com