Hob machine for communication electronic material processing

A technology of electronic materials and hobs, which is applied in the direction of metal processing machinery parts, metal processing equipment, manufacturing tools, etc., can solve problems such as damage to hobs and processing rollers, failure to adjust, damage to electronic materials, etc., to avoid excessive temperature, Avoid the effect of increasing the defective rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

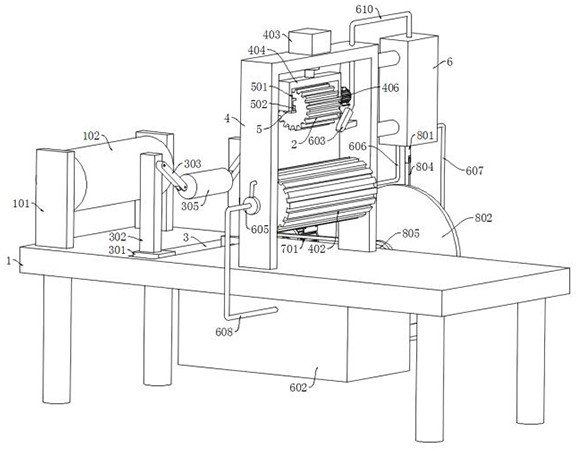

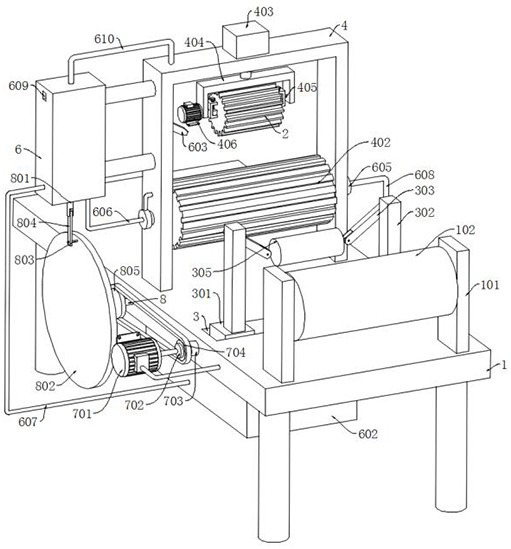

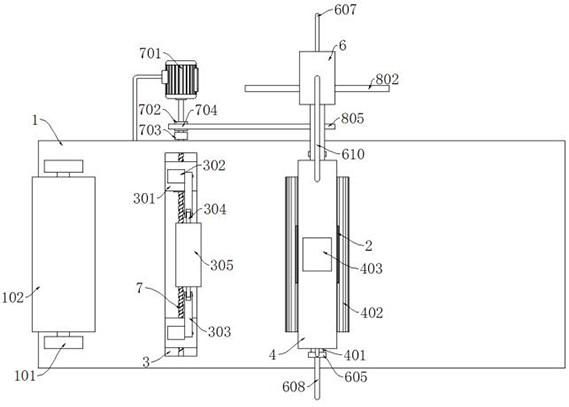

[0033] Refer Figure 1-5 , Figure 12 One communication electron material is processed with a hob, including a table 1 and a hob 2. The upper end of the table 1 is symmetrically fixedly connected to two fixing plates 101, and the two fixing plates 101 are all rotated to each other. The roller 102, the electron material can be mounted on the winding roller 102, and there is an adjustment mechanism on the table 1, and the adjusting mechanism includes a slide 3 in the upper end of the table 1, and the inner wall symmetry of the slot 3 has two sliders 301, The upper ends of the two sliders 301 are fixedly connected to two vertical rods 302, and the two vertical rods 302 side walls are rotated and connected to two connecting rods 303, and the other end of the two connecting rods 303 rotates together to connect the passive rod 304, the rod 304 side. The wall transfer is connected to the regulating roller 305, and the upper end of the table 1 is fixed to the U-shaped frame 4, the U-shaped ...

Embodiment 2

[0047] Refer Figure 6-7 The difference from the first embodiment is that the cleaning mechanism is mounted on the table 1, and the cleaning mechanism includes two vertical panels 9 that are symmetrically fixed to the upper end of the table 1, and the two vertical panels 9 are rotated from each other. The two fourth axis 901 are connected, and the two fourth axis 901 rotate together with each other, and the cleaning roller 902 is connected, and a plurality of bristles are fixed to the side wall of the cleaning roller 902, wherein one end of the fourth axis 901 penetrates the vertical panel. 9 Side wall and securely coupled with the second driven wheel 903, the active wheel 704, the first driven wheel 805, and the second driven wheel 903 are connected by the synchronous belt.

[0048] In this embodiment, when the second motor 701 is rotated to rotate the drive wheel 704, the second driven wheel 903 is rotated, and the fourth axis 901 is rotated, and the cleaning roller 902 is rotate...

Embodiment 3

[0050] Refer Figure 7-11 The difference between the present embodiment and the second embodiment is that a diachle mechanism is mounted on the table 1, and the dust collecting mechanism includes a dust tank 10 fixed to the lower end of the table 1, and there are two sides of the dust box 10 side. The vent cavity 1001 is opened in the cleaning roller 902, and a plurality of vacuum dust holes 1002 are opened in the side wall of the vacuum cavity 1001, and the other fourth axis 901 side wall is opened with a pass groove 1003, and the vacuum cavity 1001 passes through the hole groove. 1004 is connected to the pass groove 1003, and the other vertical plate 9 side wall is fixedly connected to the second rotary joint 1005 by the stent, and the other end of the fourth axis 901 penetrates the vertical plate 9 side wall and fixed to the second rotary joint 1005. The tank 10 side wall is fixedly connected to the suction tube 1006, and the other end of the vacuum tube 1006 is fixed to the sec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com