Production technique for pans

A production process and pot body technology, which is applied in the field of production and manufacture of kitchen cookware, can solve the problems that the surface treatment layer cannot reach the product, the surface treatment layer is damaged, and the product defective rate is high, so as to solve the problem of high product defective rate and cost. Low, simple process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The implementation of the present invention will be described in detail below in conjunction with the accompanying drawings, but they do not constitute a limitation to the present invention, and are only examples. At the same time, the advantages of the present invention will become clearer and easier to understand through the description.

[0027] Referring to the accompanying drawings, it can be seen that the production process of a kind of pot of the present invention can be compounded together by two modes, and the production process mode of the first pot at least comprises the following steps:

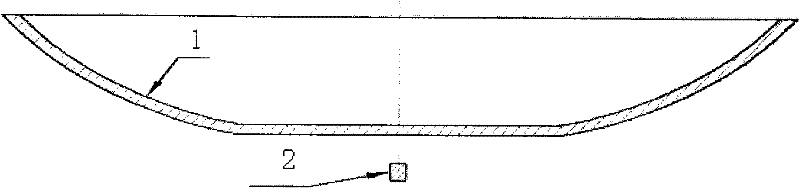

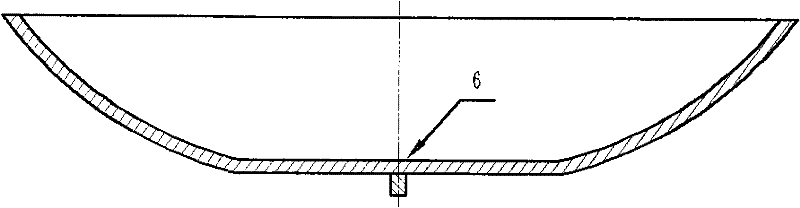

[0028] ①. Prepare the pot body 1 and spot-weld the positioning pin 2 at the bottom of the pot body 1 (such as figure 1 , figure 2 shown);

[0029] ②. Carry out special surface treatment on the inner surface of the pot body 1 after step ①;

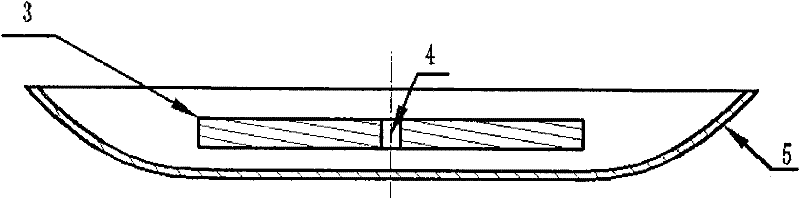

[0030] 3. Prepare the inner complex film 3 that is provided with positioning holes 4 on it, and the positioning holes 4 correspond ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com