Processing method capable for reducing defective rate of deflecting magnetic core

A processing method and defective rate technology, applied in the manufacture of inductors/transformers/magnets, electrical components, circuits, etc., to achieve the effect of reducing production costs and the method is simple and practical

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

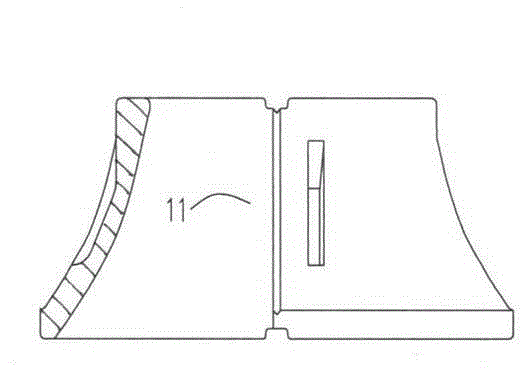

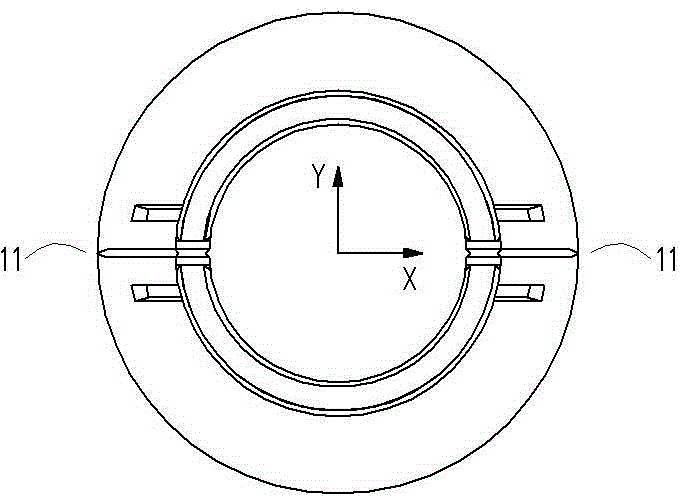

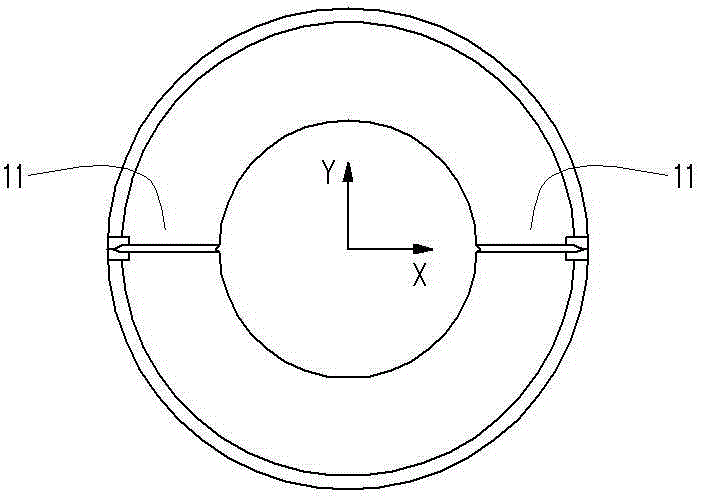

[0011] Embodiment 1: as Figure 1 to Figure 4 Shown, a kind of embodiment of the present invention comprises the following steps: a, select the die base of the deflection magnetic core die punch; b, adjust the processing size of the die punch and then process the punch: The normal size of the punch hole in the X-axis direction is increased by 50-56 wires, and the punch is processed by the slow wire cutting process, and the X-axis direction where a pair of separation ribs are located is the long axis to process an elliptical cross-sectional structure; c , using the convex mold made in step b to make the deflection magnetic core by conventional pressing process; d, sintering and molding by conventional sintering process.

[0012] The principle is: before sintering, the excessive shrinkage in the X-axis direction (the direction where the pair of separation grooves of the deflection core are located) is reserved through the size adjustment of the mold punch. When pressing the init...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com