Lead oxide containing fluoroziconate glass and preparation method thereof

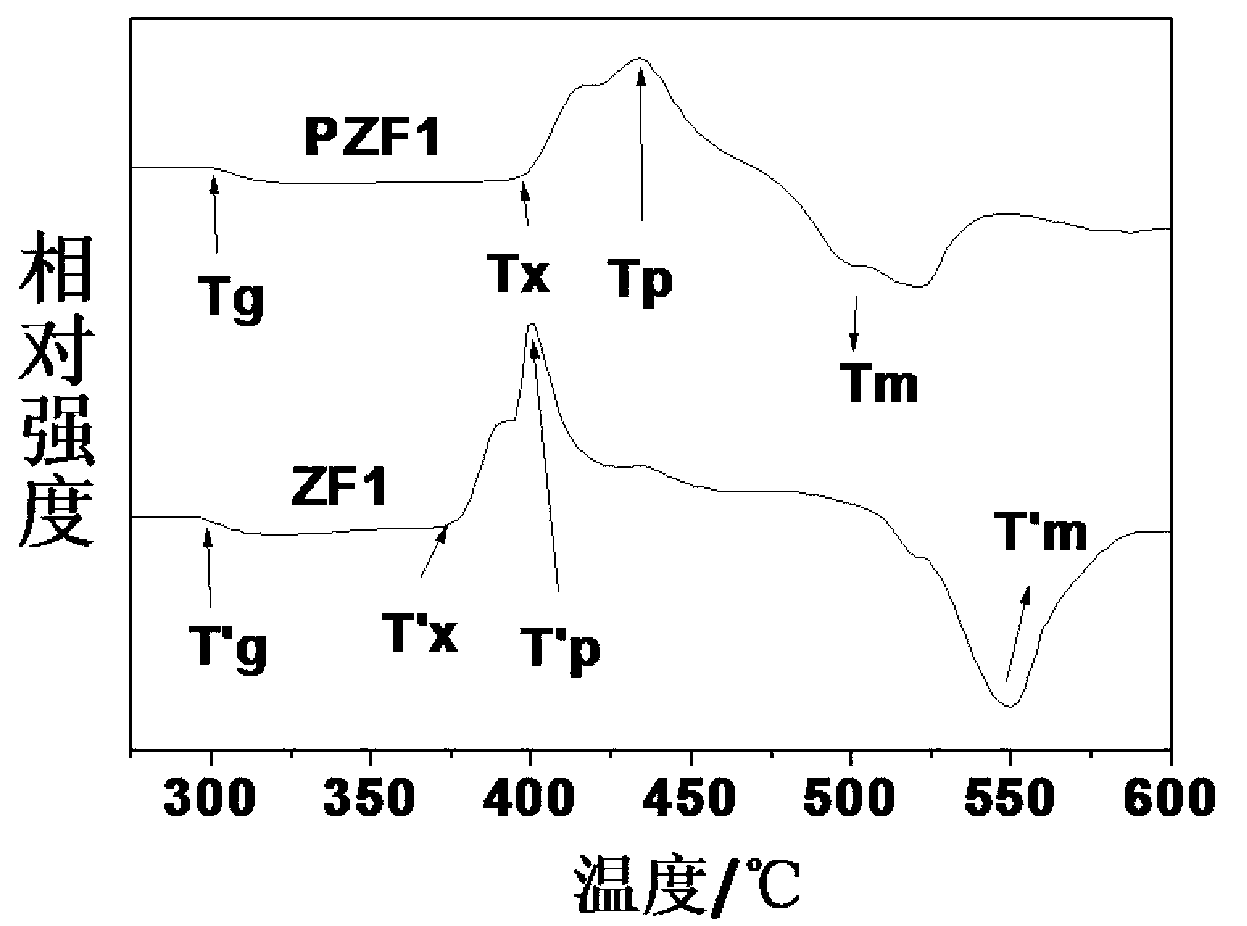

A fluorozirconate and lead oxide-containing technology, applied in the field of lead oxide-containing fluorozirconate glass and its preparation, can solve the problems of poor glass-forming performance of ZBLA and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

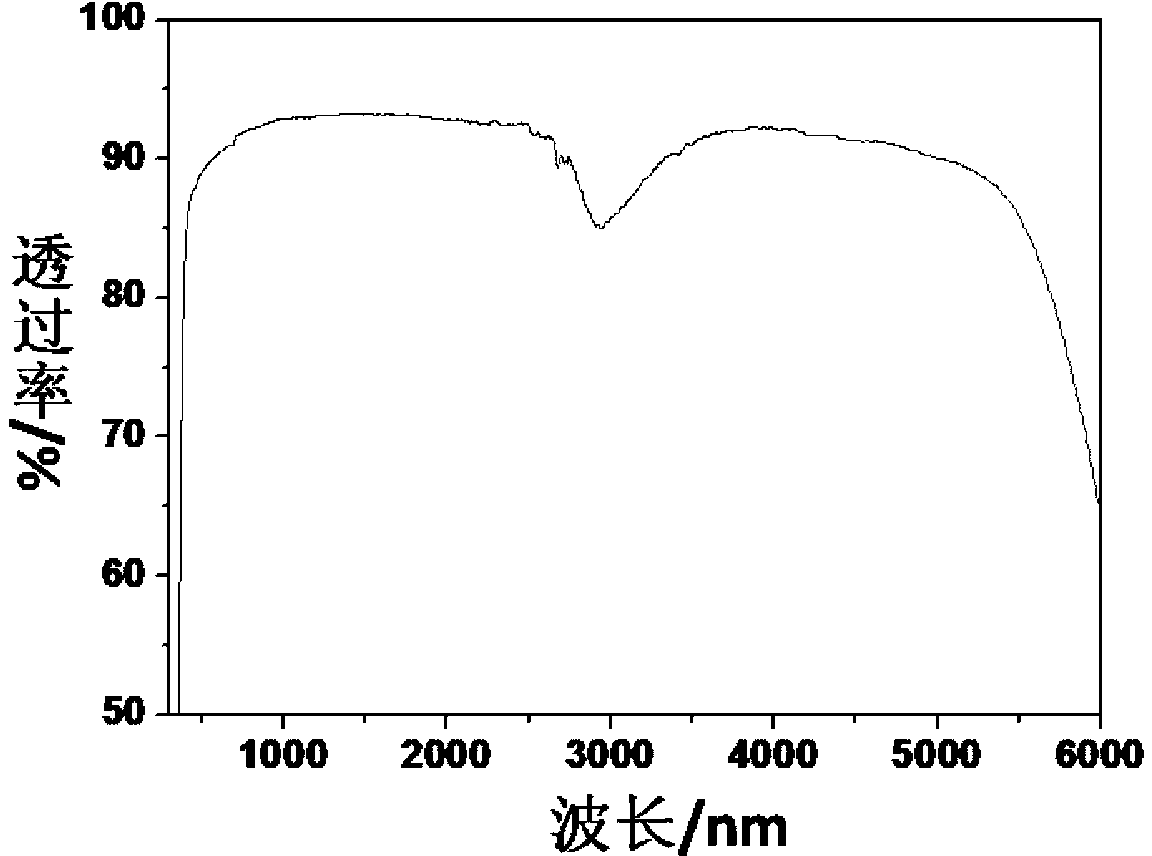

Embodiment Construction

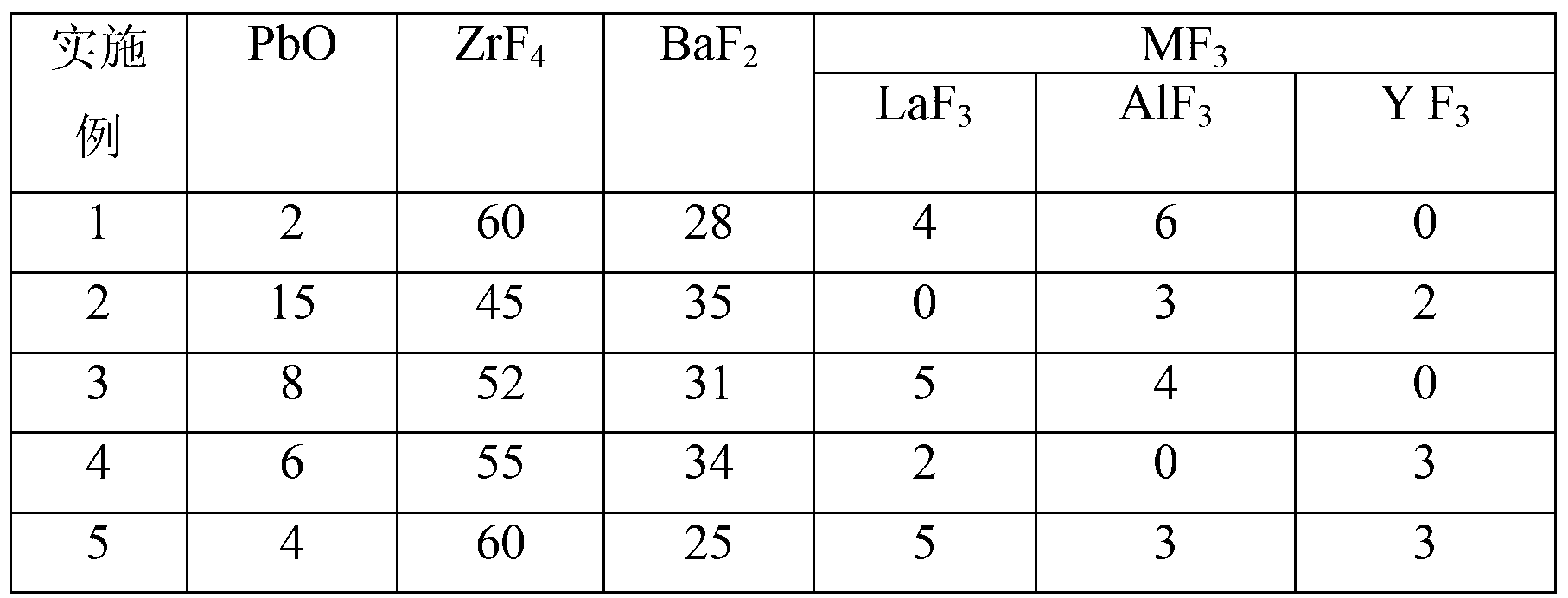

[0022] In order to further illustrate the preparation of lead oxide-containing fluorozirconate glass, this embodiment is implemented according to the technical solution of the present invention, and specific implementation methods and processes are given.

[0023] ZrF 4 Take NH 4 ZrF 5 The other fluorides are all high-purity fluoride raw materials. Concrete experimental process has provided the mole percentage composition of the raw material of the embodiment of the present invention 1,2,3,4,5 for table 1, all adopts this preparation process to carry out, carry out in two steps:

[0024] ①Prepare 1000 grams of pure fluoride powder according to a certain ratio. After fully mixing, put it into a platinum crucible. Put the crucible into the furnace and raise the temperature to 850°C for 30 minutes. After fully melting, take it out and pour it directly on the template On, the clinker of pure fluorozirconate is obtained;

[0025] ② Weigh 1000 grams of clinker, put it back into ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com