Fluorozirconate glass containing tellurium dioxide

A technology of fluorozirconate and glass, applied in the field of fluorozirconate glass containing tellurium dioxide

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

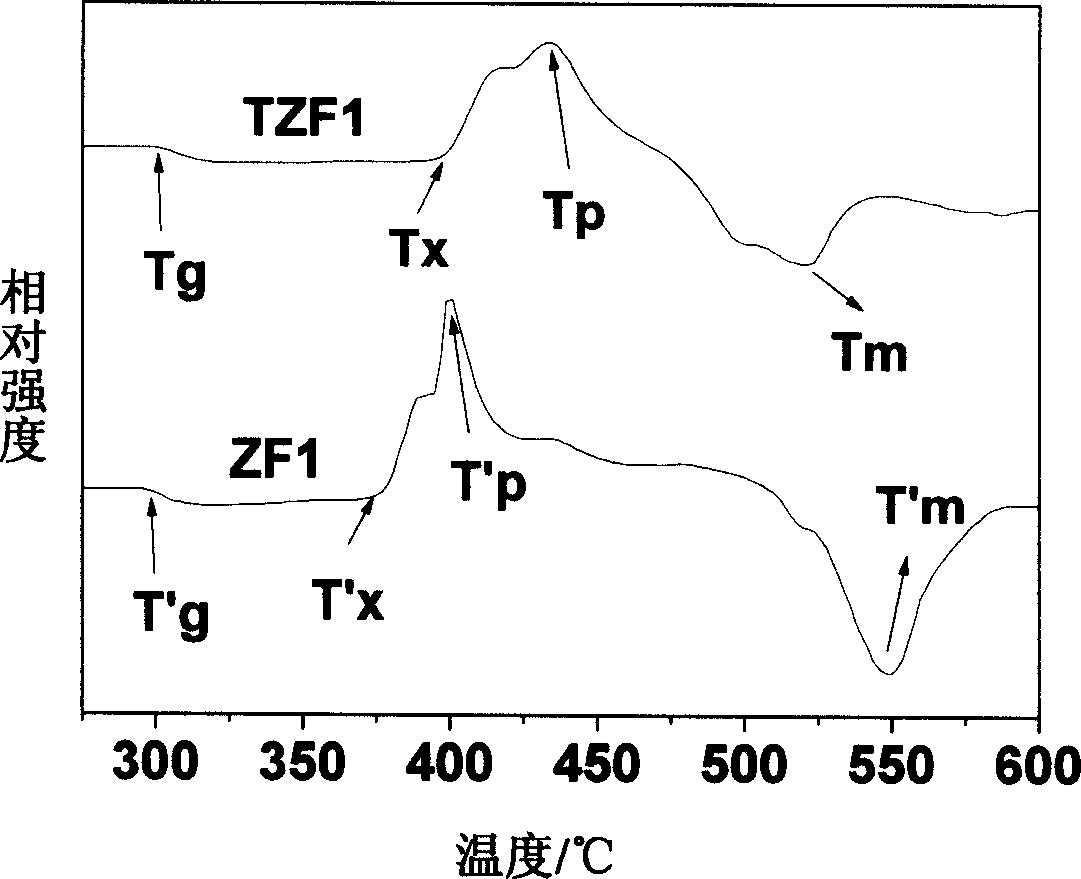

[0017] figure 1 Respectively the embodiment of the present invention 6 (TZF1) and pure fluoride composition 57ZrF 4 ·34BaF 2 4.5LaF 3 4.5AlF 3 (ZF1) Differential thermal (DTA) curves of the prepared glass. Among them, the ΔT of the glass corresponding to the TZF1 curve is 80°C, and the S is 6.78; while the ΔT of the glass corresponding to the curve ZF1 is 100°C, and the S is 12. Larger ΔT (ΔT=T x -T g ) and S(S=(Tx-Tg)(Tp-Tx) / Tg) values indicate that TZF1 has better glass-forming properties than ZF1, and is suitable for preparing large-scale infrared materials.

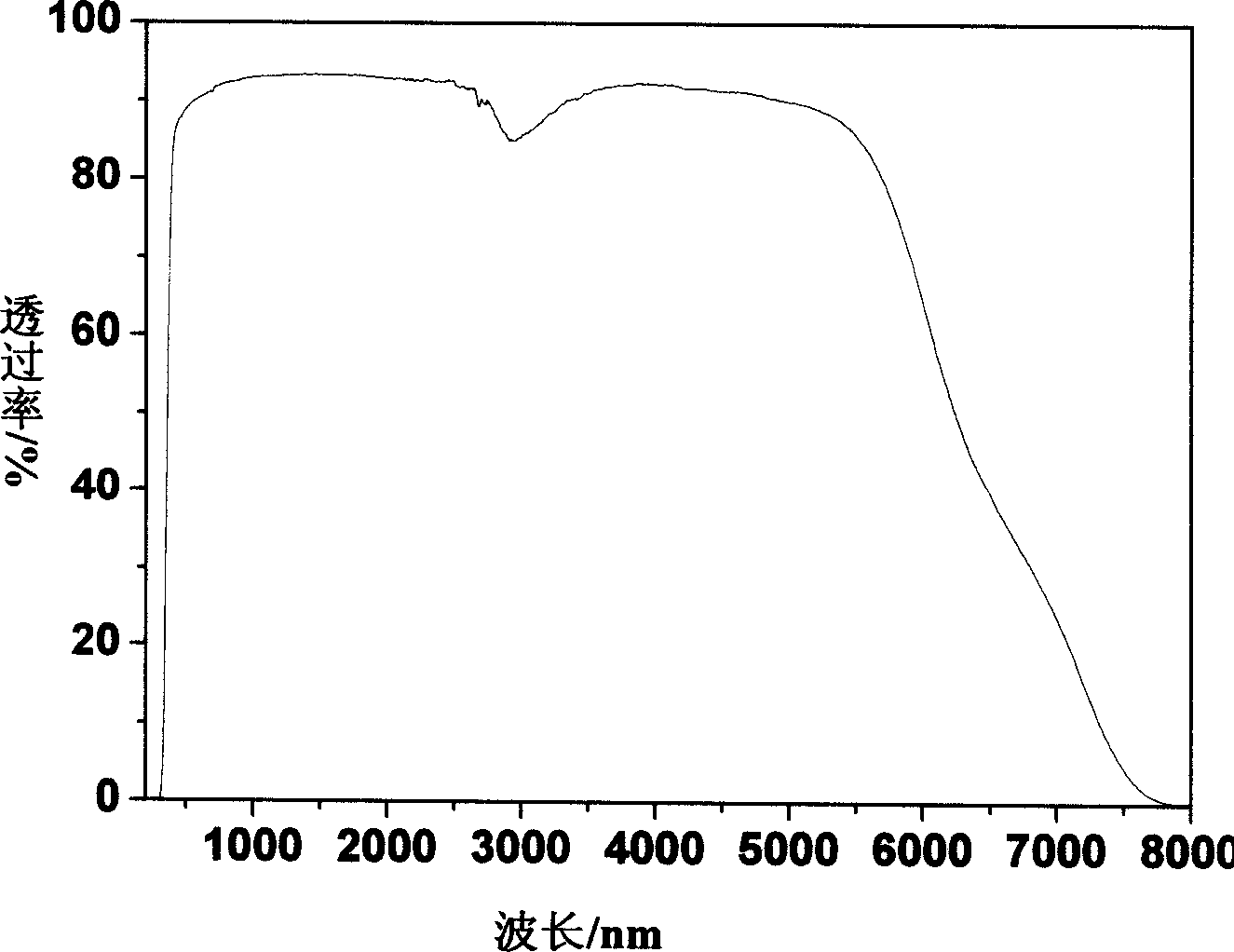

[0018] figure 2 It is the transmittance curve of the glass sample (sample thickness: 6mm) in Example 6 of the present invention at 0.3-7.0um. It can be seen from the figure that the fluorozirconate glass containing tellurium dioxide of the present invention has good transmittance from near ultraviolet to mid-infrared.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com