Green-light upconversion lanthanium titanate-based paramagnetic glass material and preparation method thereof

A technology of lanthanum titanate-based and glass materials, which is applied in the field of green light up-conversion lanthanum titanate-based paramagnetic glass materials and green light up-conversion luminescent glass materials, can solve the problem of restricting the development and application of heavy metal oxide luminescent glass materials, difficult problems. Obtain heavy metal oxide glass, difficult to obtain glass block and other problems, to achieve the effect of improving density and thermal stability, rapid solidification, and avoiding contact with the wall

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

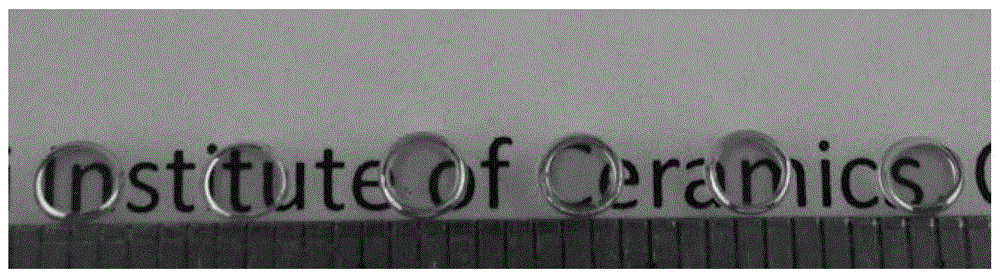

[0037] According to the formula Ti 2.25 La 0.78-x Gd x Er 0.04 Yb 0.18 o 6 , (x=0.10) Weigh the corresponding oxides and mix them uniformly. Then the mixed powder was sintered at 800°C for 12 hours in the air, and then cooled down naturally. Then, the sintered powder is pressed into tablets by a tablet machine at a pressure of 7 MPa, and pressed into a disc shape of 90-100 mg. Finally, it was melted and solidified in an air suspension furnace without a container. The throat diameter of the nozzle was 2mm, the laser power was 100w, and the holding time was 4 minutes. The gas used to achieve air suspension was air, and the pressure was 7MPa. Finally, block titanic acid was obtained. Lanthanum-based glass.

Embodiment 2

[0039] According to the formula Ti 2.25 La 0.78-x Gd x Er 0.04 Yb 0.18 o 6 , (x=0.15) Weigh the corresponding oxides and mix them uniformly. Then the mixed powder was sintered at 800°C for 12 hours in the air, and then cooled down naturally. Referring to Example 1, the bulk lanthanum titanate-based glass was finally obtained by pressing into tablets and laser melting.

Embodiment 3

[0041] According to the formula Ti 2.25 La 0.78-x Gd x Er 0.04 Yb 0.18 o 6 , (x=0.20) Weigh the corresponding oxides and mix them uniformly. Then the mixed powder was sintered at 800°C for 12 hours in the air, and then cooled down naturally. Referring to Example 1, the bulk lanthanum titanate-based glass was finally obtained by pressing into tablets and laser melting.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com