Composite accumulator

A technology of accumulators and pressure sensors, applied to accumulator devices, pressure vessels, and methods for container discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0061] The following description is merely exemplary in nature and is not intended to limit the invention, the application or uses of the invention.

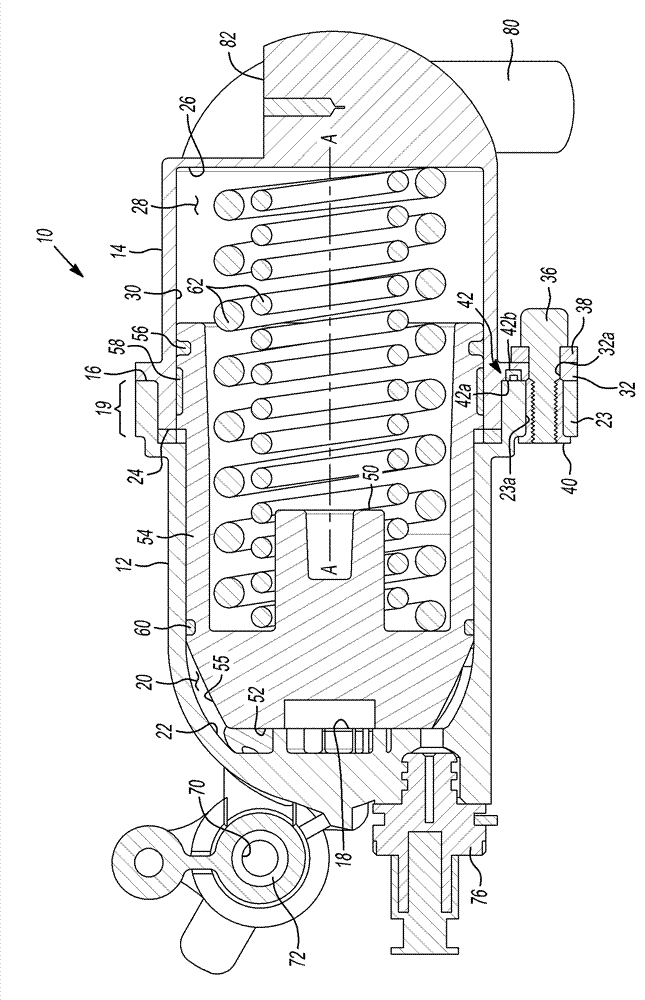

[0062] Referring to the drawings, reference numeral 10 generally indicates an accumulator in accordance with the principles of the invention. The accumulator 10 is an energy storage device within which incompressible hydraulic fluid is maintained under pressure by an external source. In the example provided, the accumulator 10 is a spring-type accumulator that provides a compressive force on hydraulic fluid within the accumulator 10, as will be described in more detail below. The accumulator 10 is preferably used in a hydraulic control system of an automatic transmission (not shown) to enable stop-start operation or hybrid hydraulic operation. It should be appreciated, however, that the accumulator 10 may also be used in various other environments without departing from the scope of the present invention, such as in fuel inject...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com