Wheel groove finish broach tooth profile numerical control grinding process

A technology of wheel groove broach and finishing broach, which is applied in the direction of broach, grinding/polishing equipment, grinding/polishing safety device, etc., which can solve the problems of high price, achieve high relief grinding precision and reduce cutting load , Improve the effect of wheel groove broaching effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] A kind of wheel groove broach tooth profile numerical control grinding process of the present invention comprises the following steps:

[0026] 1. If figure 1 As shown, put the wheel groove broach 2 on the sinusoidal magnetic table 1, use Picture 1-1 The shown grinding wheel 3 performs rough grinding and semi-fine grinding on the tooth shape of the wheel groove broach; artificial aging treatment is performed on the wheel groove broach to eliminate the internal stress of the wheel groove broach and reduce the damage caused by the strong grinding of the broach. out of shape.

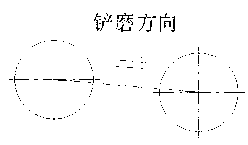

[0027] 2. Use Figure 4 shown and Figure 5 Fine grinding wheels with the tooth profile shown, fine grinding wheel groove broach tooth profile. On the CNC precision surface forming grinding machine, use a diamond roller or a dresser with a diamond pen to accurately trim the fine grinding wheel for the tooth profile of the groove broach, and control the error value of the tooth profile of the gr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com