Central Suspension Self-Leveling Bogie for Railway Vehicles

A railway vehicle and suspension type technology, which is applied in the field of suspension type self-heightening bogies, can solve the problems of wheel and rail maintenance workload and maintenance cost increase, affecting the safety of vehicle operation, wheel and rail wear and so on.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

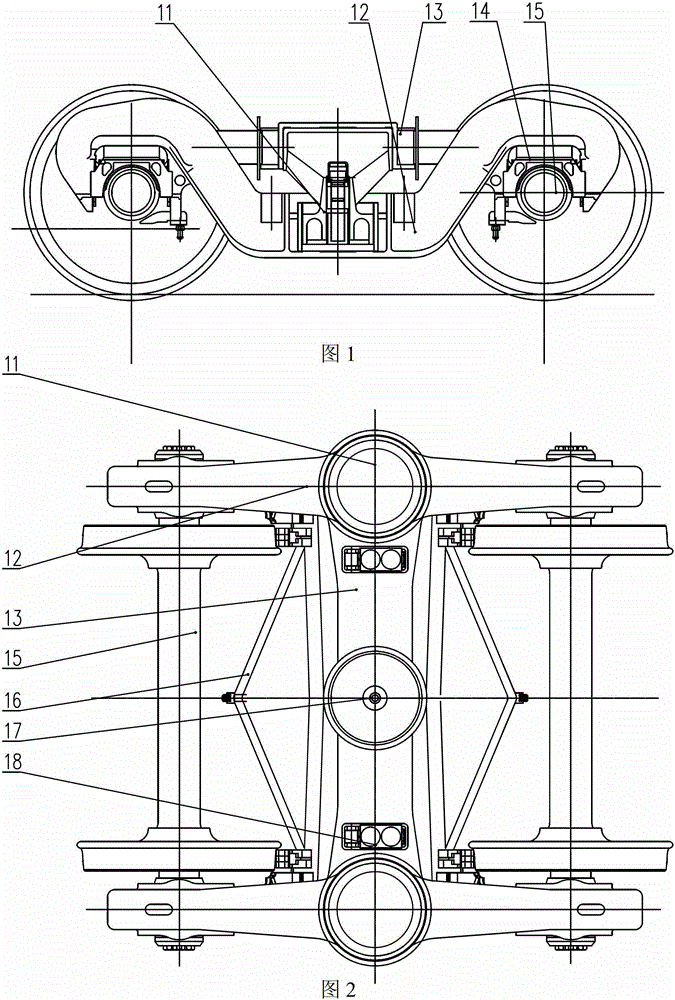

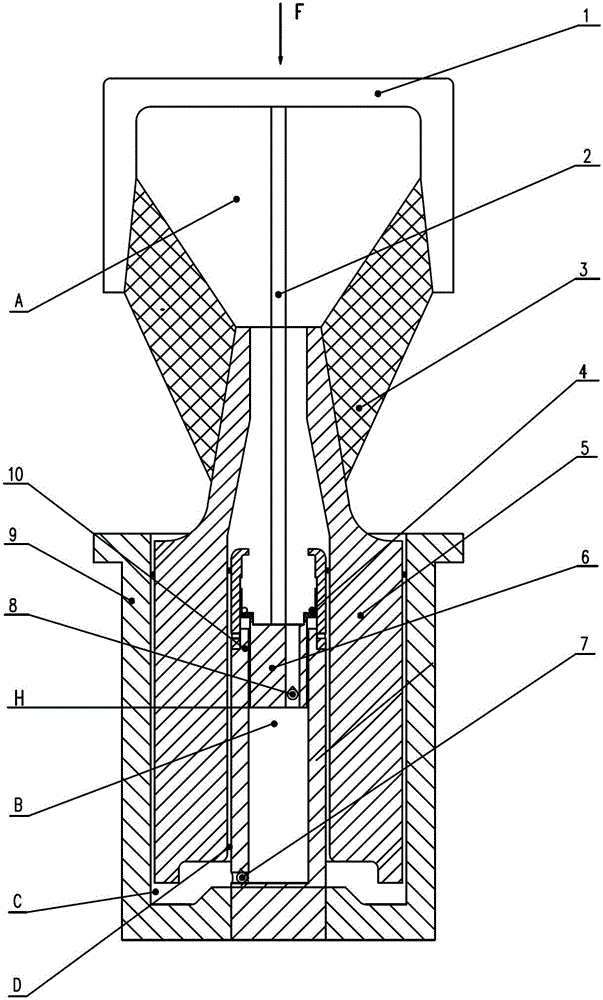

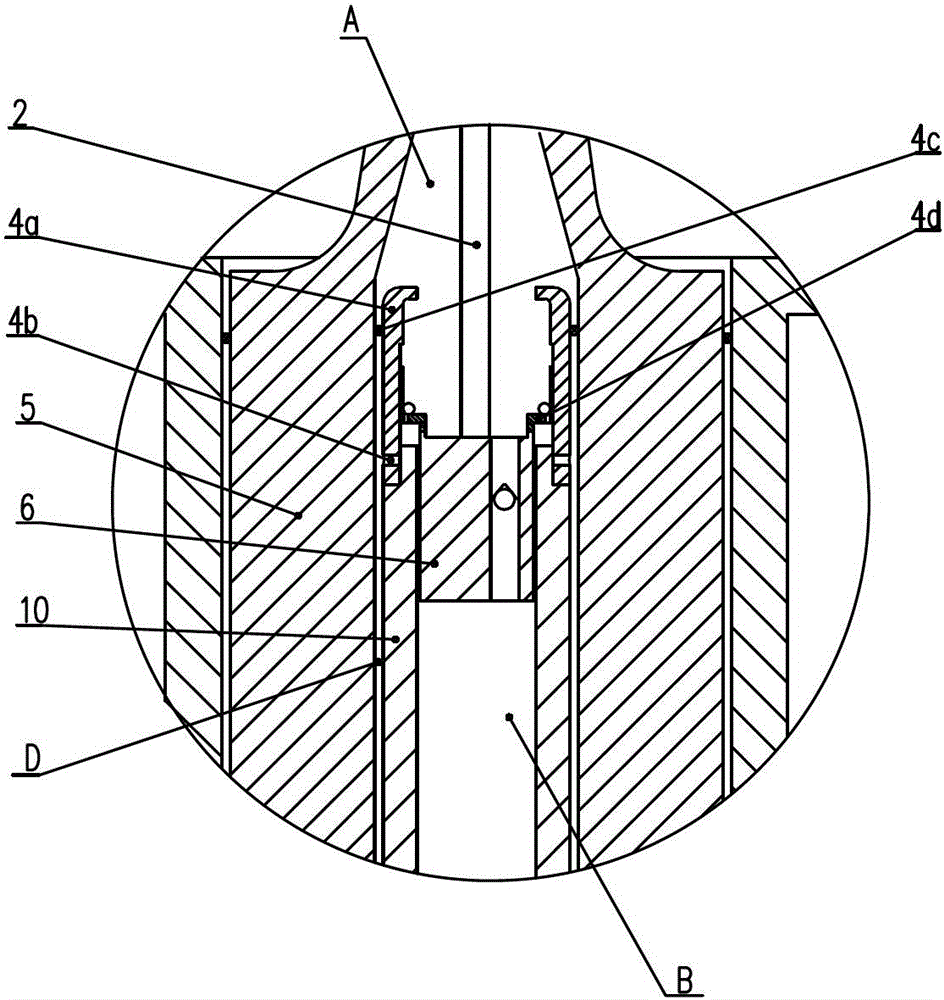

[0041] Such as Figure 1~2 The centrally suspended self-heightening bogie of a railway vehicle as shown includes a wheel axle composition 15, a side frame composition 12, a bolster 13, and a corresponding foundation braking device 16, and the pedestals at both ends of the side frame composition 12 are suspended through the axle boxes The device 14 is placed on the wheel shaft assembly 15, the center of the bolster 13 is provided with a lower center plate 17, the two sides of the bolster 13 are provided with lower side bearings 18, the two ends of the bolster 13 and the side frame form the central frame of 12 A spring deflection automatic adjustment device 11 is arranged between them, and the spring deflection automatic adjustment device 11 can choose a variety of structural forms, two of which are specifically introduced below.

[0042] Such as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com