Railway vehicle bogie center disk automatic height adjusting device

An automatic adjustment device, a technology for railway vehicles, which is applied in the direction of the device for lateral relative movement between the underframe and the bogie, and can solve the problems of easy breakage of the coupler, shortened service life, and inability to effectively reduce the force of wheel-rail action.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

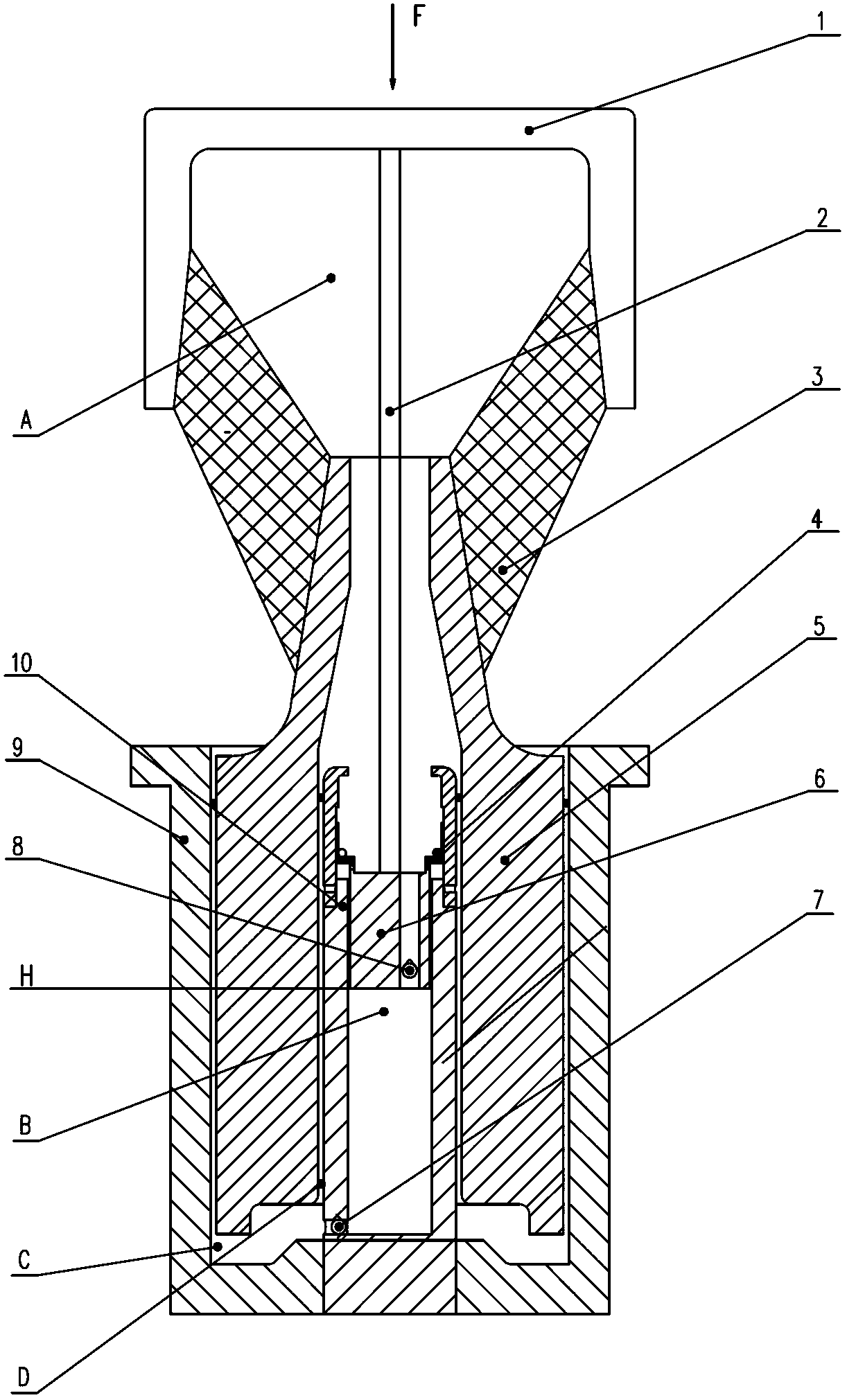

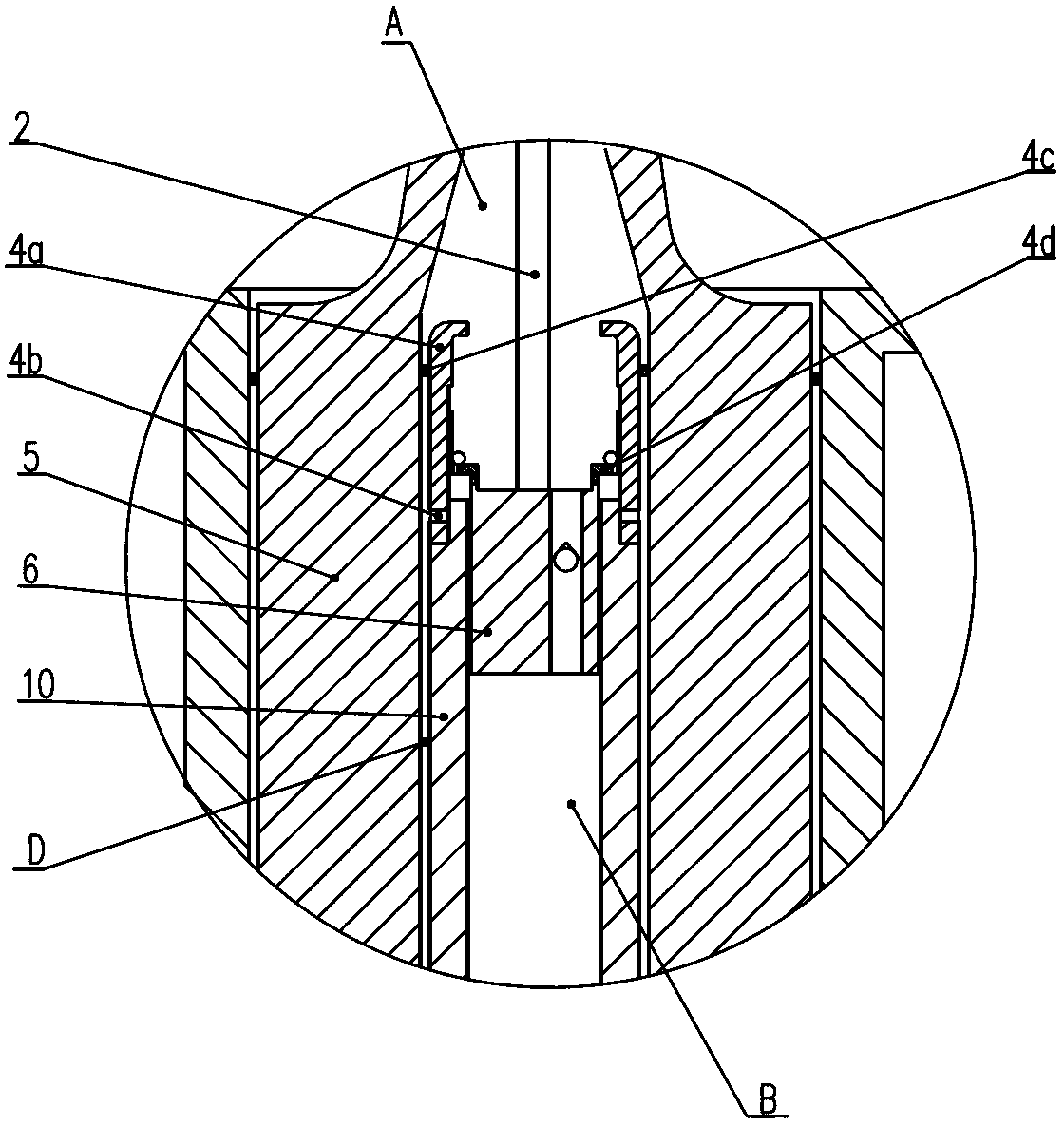

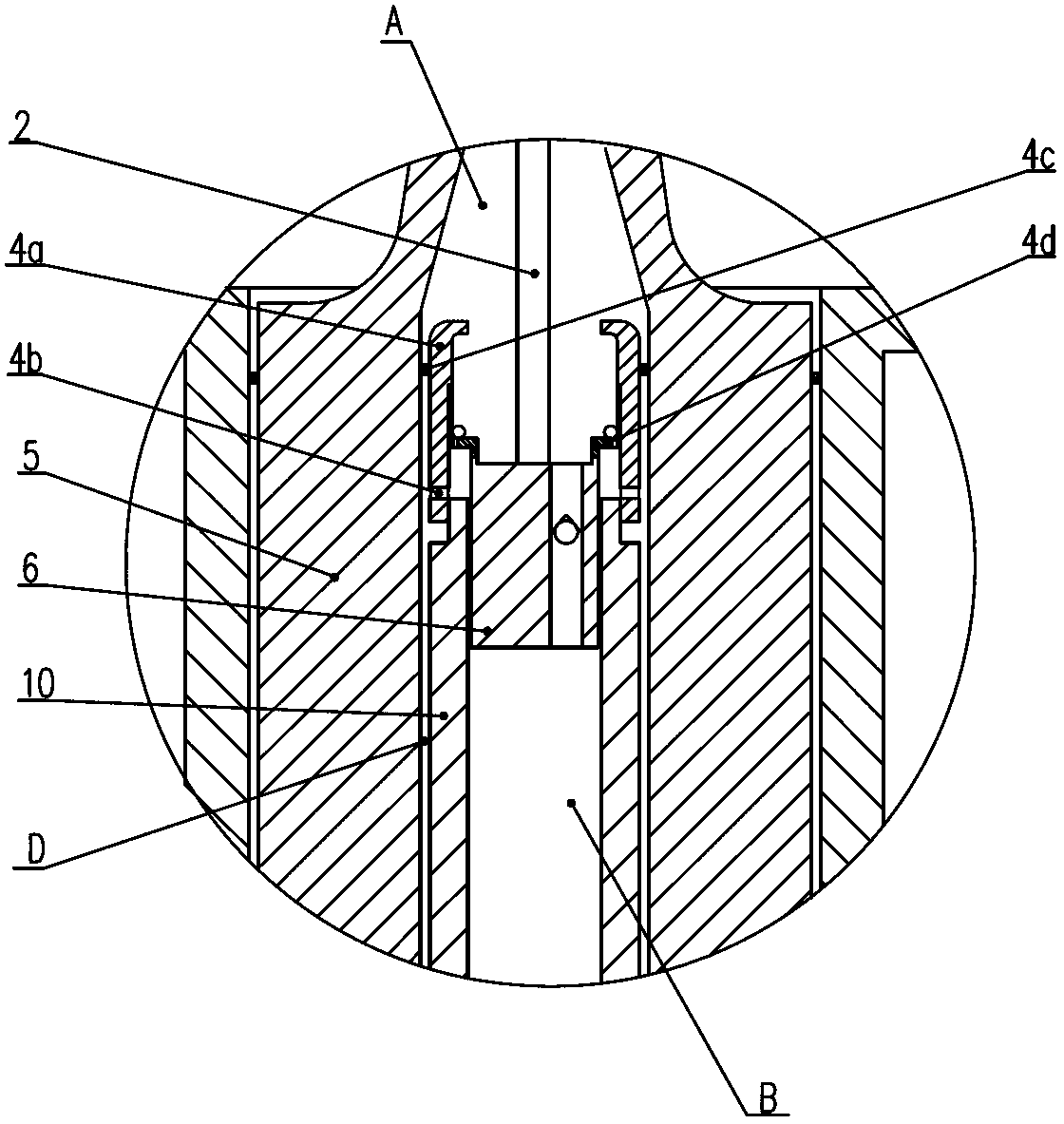

[0039] Such as Figure 1~4 The first type of automatic adjustment device for the height of the center plate of the railway vehicle bogie shown has an outer cylinder 9 that also serves as a mounting base. The outer cylinder 9 is provided with an outer piston 5, the outer piston 5 has a cavity structure, and the top of the outer piston 5 The outer cylinder 9 extends out and is connected to the bearing top cover 1 through a rubber bearing spring 3 in the shape of a hollow revolving body. In this embodiment, the load-bearing top cover 1 is in the shape of an inverted cup, the top profile of the outer piston 5 protruding out of the outer cylinder 9 is in the shape of a frustum, and the rubber load-bearing spring 3 is in the shape of a hollow revolving body with a rhombus in cross section. The revolving surface is vulcanized and combined with the inner wall of the inverted cup carrying the top cover 1 and the inner revolving surface of the lower part is vulcanized and combined with th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com