disk device

A technology of guiding part and inserting port, which is applied in the direction of record information storage and instrumentation, and can solve problems such as poor disk delivery and easy collision of disks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

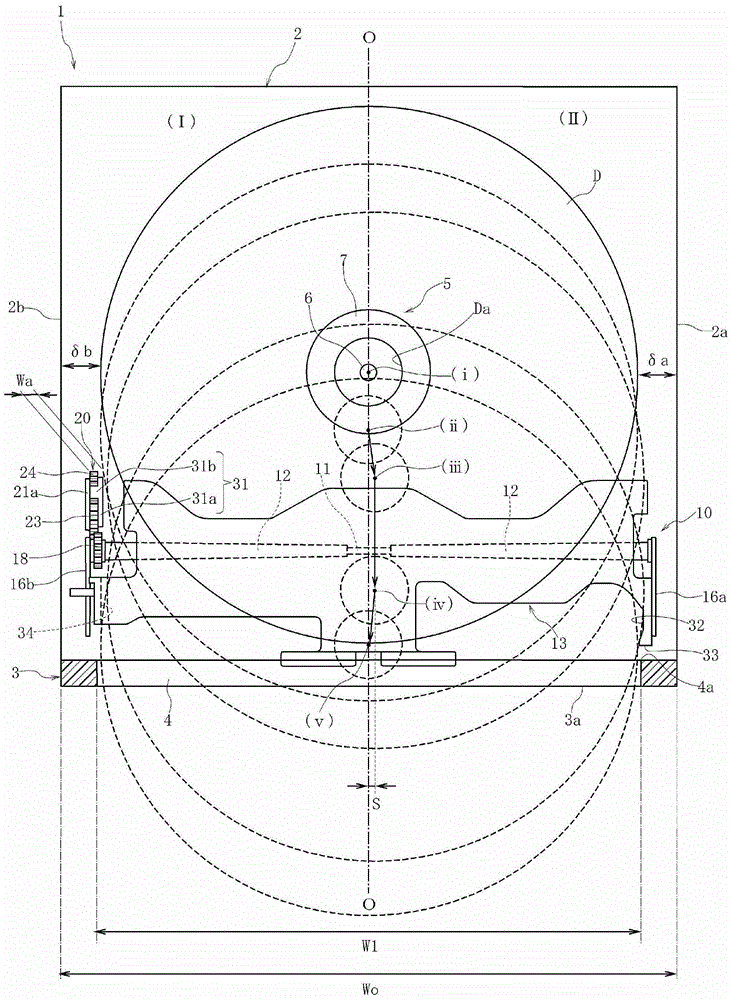

[0047] figure 1 The shown disk device 1 has a metal casing 2 and a synthetic resin panel 3 provided in front of the casing 2. On the panel 3, along the figure 1 There is an insertion port 4 in the shape of an elongated slit in the left-right direction opening. The casing of the disk device 1 is constituted by the housing 2 and the panel 3 .

[0048] The panel device 1 is for a vehicle, and the housing 2 is embedded in an instrument panel or instrument panel in a vehicle cabin, and is provided so that the panel 3 is exposed on the surface.

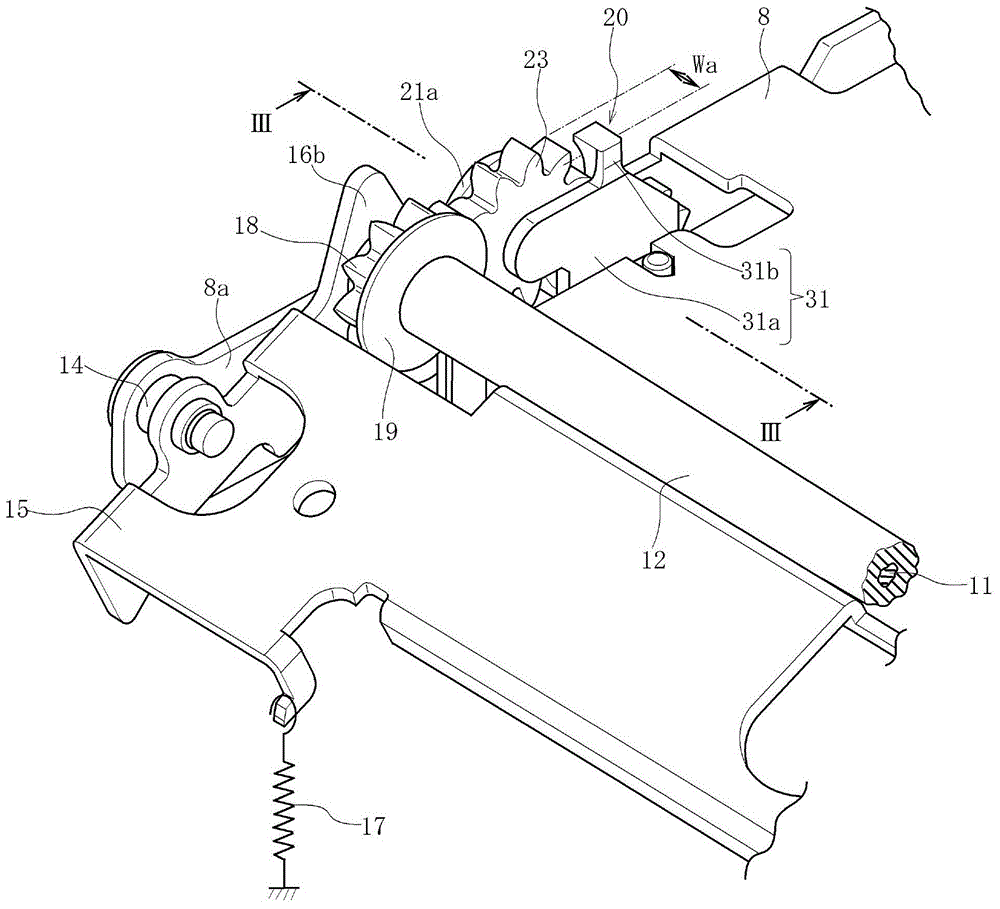

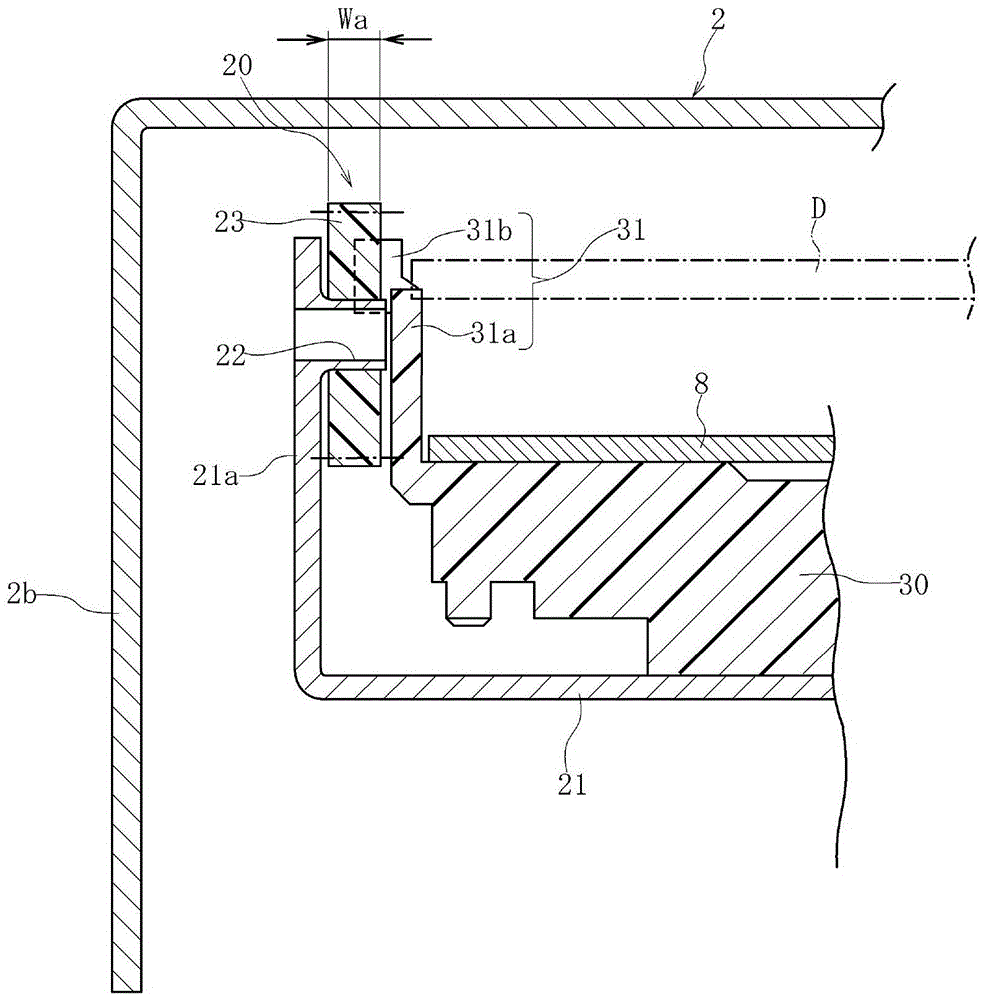

[0049] Inside the frame 2 there are figure 2 The mechanism base 8 is shown. The mechanism base 8 is supported by elastic members such as oil dampers and tension coil springs inside the frame body 2 . Such as figure 1 As shown, a rotation drive unit 5 is provided inside the frame body 2 . The rotary drive unit 5 includes a rotary shaft 6 , a turntable 7 fixed to the rotary shaft 6 , a spindle motor for rotating the rotary shaft 6 , an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com