Friction dampers for reducing elevator car movement

An elevator car and damping technology, which is applied to elevators in buildings, lifting equipment in mines, winch devices, etc., can solve problems such as noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

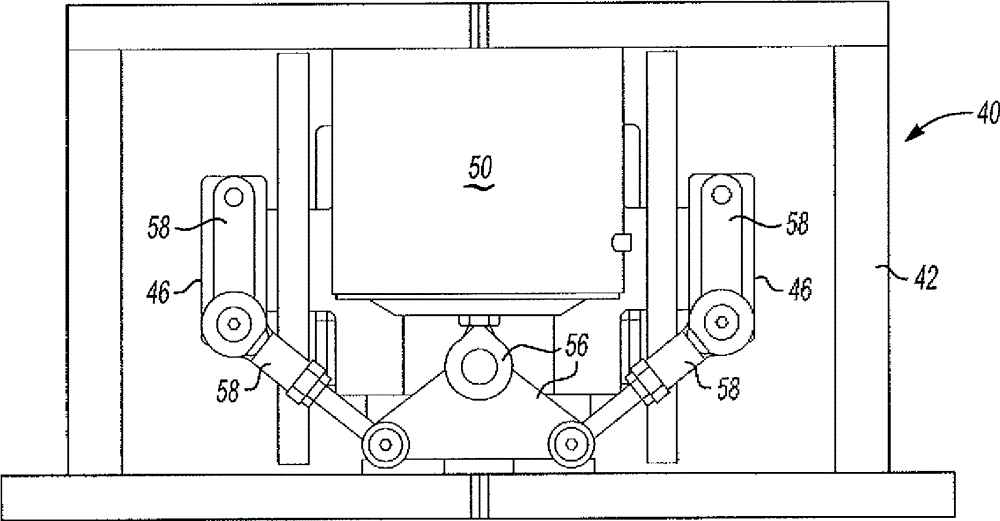

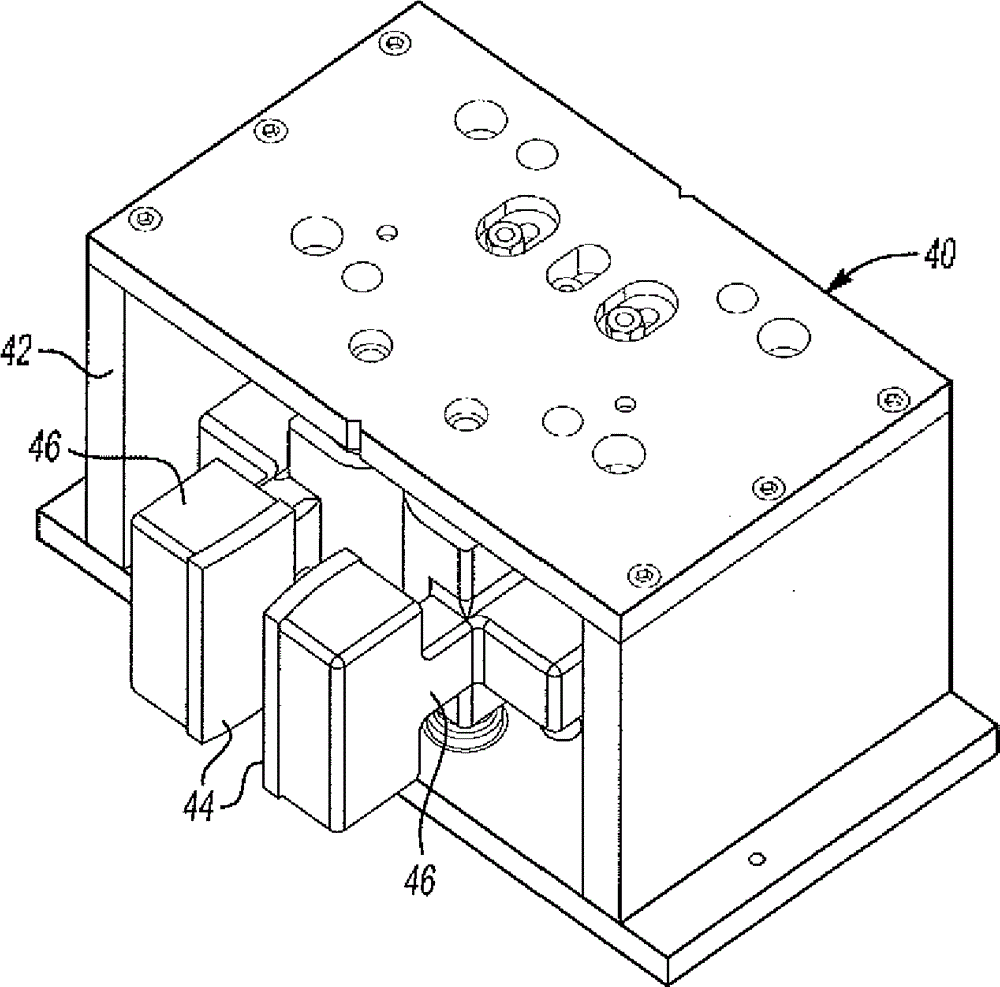

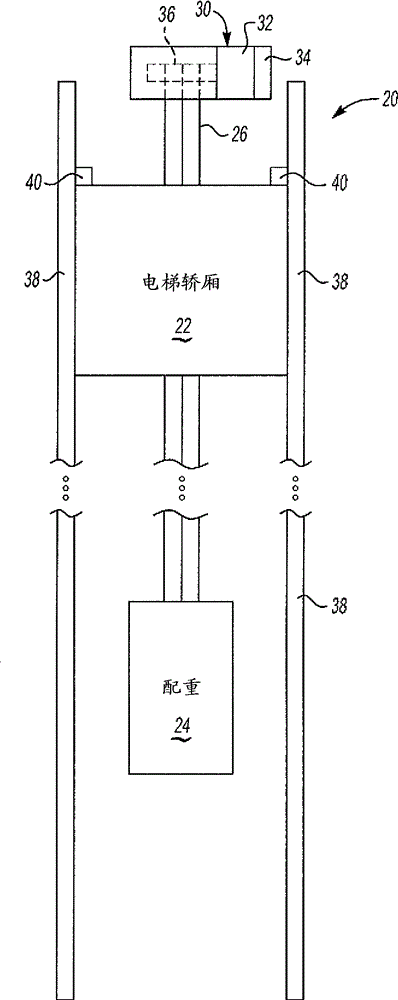

[0014] figure 1 Selected portions of exemplary elevator system 20 are shown schematically. Elevator car 22 is coupled with counterweight 24 . A plurality of load bearing members 26 serve as lanyard arrangements for suspending the load of the elevator car 22 and counterweight 24 . In one example, load bearing member 26 includes a flat belt.

[0015] Elevator machine 30 includes motor 32 and brake 34 to control movement of traction sheave 36 . Traction between load bearing member 26 and traction sheave 36 provides control over the movement and position of elevator car 22 . For example, motor 32 causes rotation of traction sheave 36 , which rotation causes movement of load bearing member 26 to achieve the desired movement of elevator car 22 along guide rail 38 .

[0016] A brake 34 is used to prevent rotation of the traction sheave 36 in order to stop the elevator car 22 at a desired vertical position along the guide rail 38 . In one example, load bearing member 26 is of a c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com