Indoor dry powder intelligent fire extinguishing system

A fire-extinguishing system and dry powder technology, applied in the field of fire-extinguishing systems, can solve problems such as inability to spray water, inability to extinguish flames, and limited fire-extinguishing effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

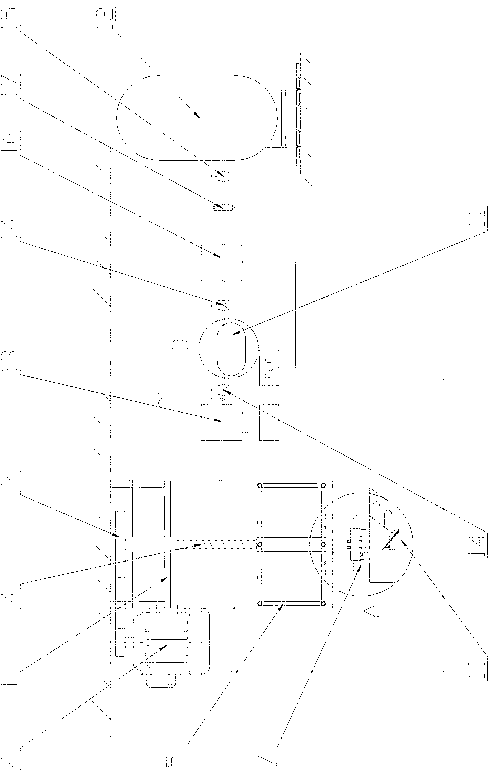

[0019] The specific implementation manner of the present invention will be described below with reference to the accompanying drawings. Such as figure 1 , figure 2 , image 3 , Figure 4 Shown: an indoor dry powder intelligent fire extinguishing system, the fire extinguishing system includes a fixed frame 1, the fixed frame 1 is set at a high place indoors (such as in the ceiling), and a lifting motor 2 is arranged on the fixed frame 1, the The output end of the lifting motor 2 is connected with the lifting gear 3 through the gear transmission pair, and the lifting gear 3 can rotate coaxially with the lifting screw 4. The lifting screw 4 is covered with a lifting frame 5 matching its thread. The lower end is provided with a turntable 7, which is controlled by a rotating motor 6. On the turntable 7, an infrared thermometer 8, an infrared range finder 9 and a telescopic nozzle 10 are arranged, wherein the telescopic nozzle 10 passes through the pipeline and the dry powder co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com