Tool for manufacturing stay wire

A technology of special tools and wire clips, which is applied in the field of special tools for pulling wires, and can solve problems such as easy damage to the anti-corrosion layer of wire clips, difficulty in grasping the size of the curvature, and affecting the installation quality of wire clips, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

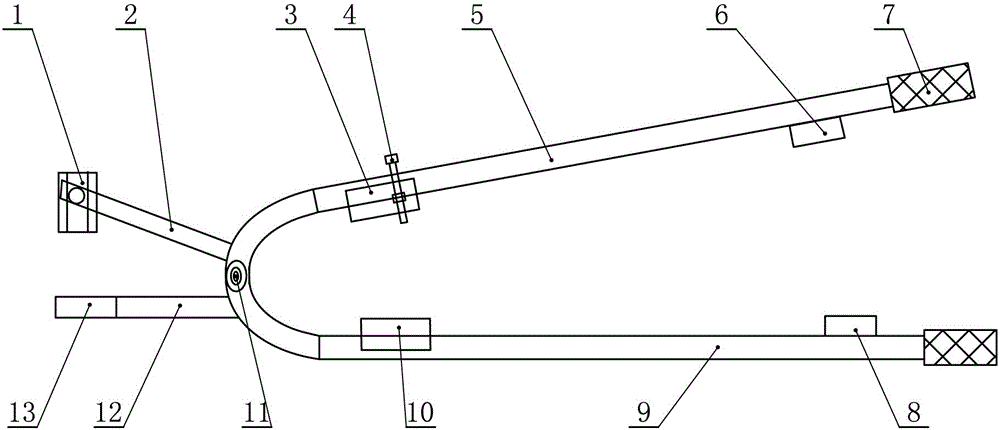

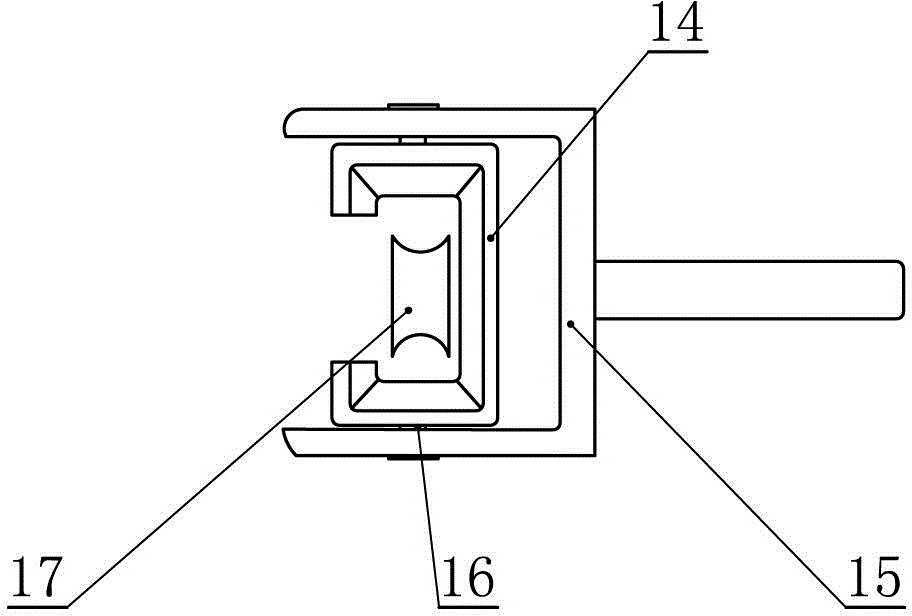

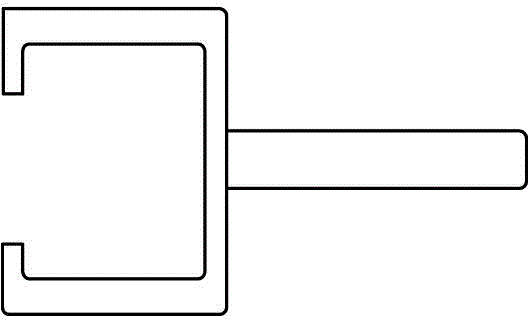

[0018] The present invention as figure 1 , 2 , shown in 3, 4, 5, 6, a kind of backguy making special tool, comprises upper steel pipe 5 and lower steel pipe 9, last steel pipe 5 and lower steel pipe 9 are connected by pin 11, the connecting end of upper steel pipe 5 and lower steel pipe 9 It is arc-shaped, and it is characterized in that: the inner side of the right part of the upper steel pipe 5 and the lower steel pipe 9 is fixedly connected with the upper positioning pipe 6 and the lower positioning pipe 8, and the left parts of the upper steel pipe 5 and the lower steel pipe 9 are respectively fixedly connected with an upper steel hinge line Seat 3 and lower steel hinge line seat 10. In this embodiment, the left side of the connecting end of the upper steel pipe 5 and the lower steel pipe 9 is respectively fixedly connected with a cable clip co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com