Optical bonding member and touch display device

A technology for touch devices and display devices, applied in the direction of adhesives, film/sheet-like adhesives, etc., can solve the problems of rising production costs and increasing steps, avoiding specular reflection, reducing refraction and scattering, and avoiding cumbersome processes. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

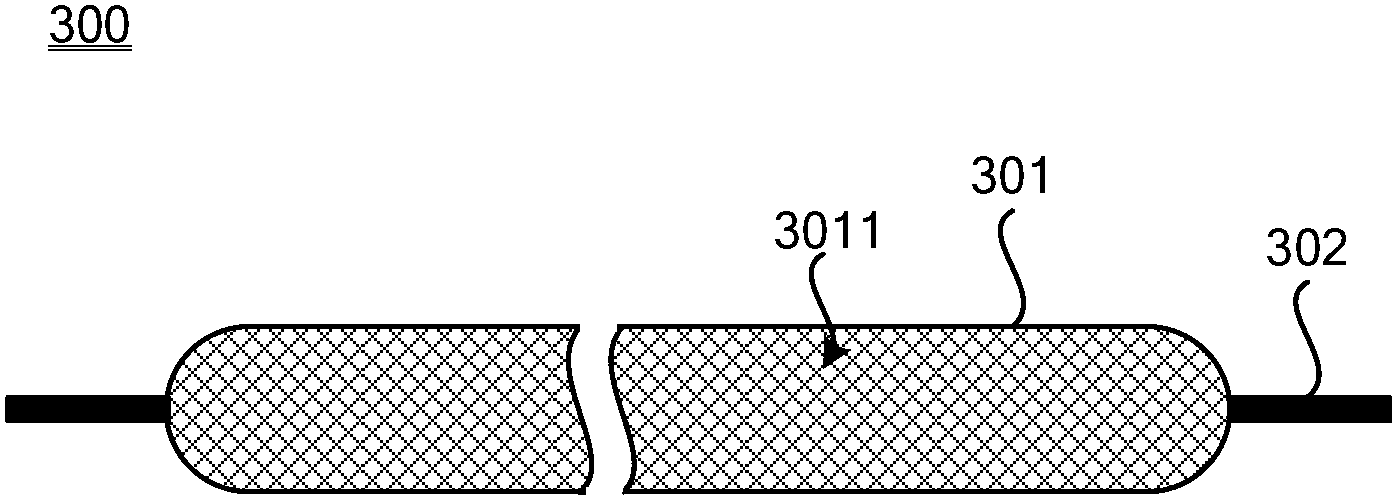

[0031] Such as image 3 As shown, the optical bonding member 300 of this embodiment is used for bonding a display device and a touch device. The optical bonding member 300 includes a capsule structure 301 and an adhesive annular sheet structure 302 located around the capsule structure 301 , wherein the capsule structure 301 is filled with liquid optical glue 3011 . The material for bonding the annular sheet structure 302 and the capsule structure 301 is, for example, PE or PET.

[0032] Such as Figure 4 As shown, when the optical adhesive 300 is bonding the display device 400 and the touch device 500, the capsule structure 301 is located between the display device 400 and the touch device 500, and corresponds to the display area AA of the display device 400 , the adhesive annular sheet structure 302 is located in the peripheral area of the display area AA of the display device 400 , and is used for bonding the display device 400 and the touch device 500 together.

[0033...

Embodiment 2

[0037] Such as Figure 5 As shown, the touch display device 600 of this embodiment includes: a display device 400, a touch device 500, and the optical bonding member 300, and the display device 400 and the touch device 500 are bonded through the adhesive annular sheet Structure 302 is glued together. The capsule structure 301 is filled with liquid optical glue 3011, and the thickness H1 of the capsule structure 301 after filling the liquid optical glue 3011 is 0.2mm˜0.3mm.

[0038] The optical adhesive in this embodiment is basically the same as the optical adhesive in Embodiment 1. The following only describes the differences between the optical adhesive in this embodiment and the optical adhesive in Embodiment 1. Other Part of it can refer to Example 1.

[0039] continue to refer Figure 5In order to ensure the stability of bonding of the touch display device 600 , after the touch display device 600 is assembled, the peripheral thickness H2 of the optical adhesive member ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com