A kind of multi-layer bubbling foil dynamic pressure gas thrust bearing

A technology of thrust bearings and bubble foils, applied in the field of multilayer bubble foil dynamic pressure gas thrust bearings, can solve problems such as frictional damage of bearings and rotors, excessive friction on bearing surfaces, and restrictions on the application of turbomachinery, etc., to achieve Effects of increased load carrying capacity, improved stiffness characteristics, improved stiffness distribution and assembly characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in detail below in conjunction with the accompanying drawings.

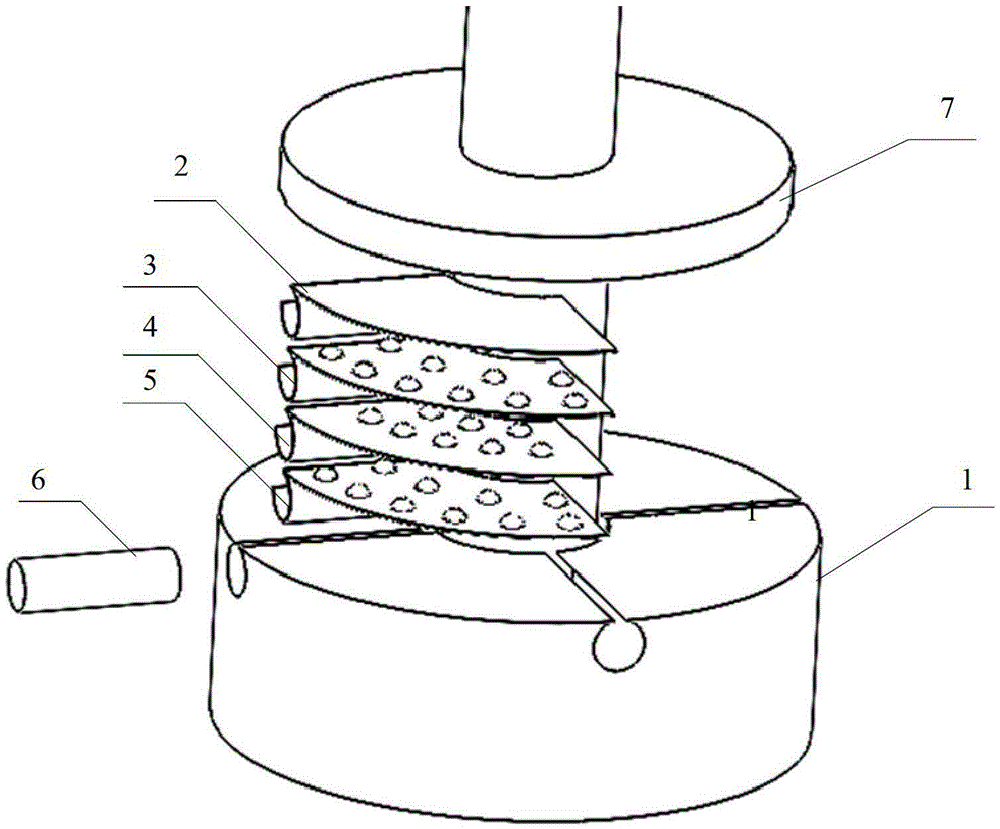

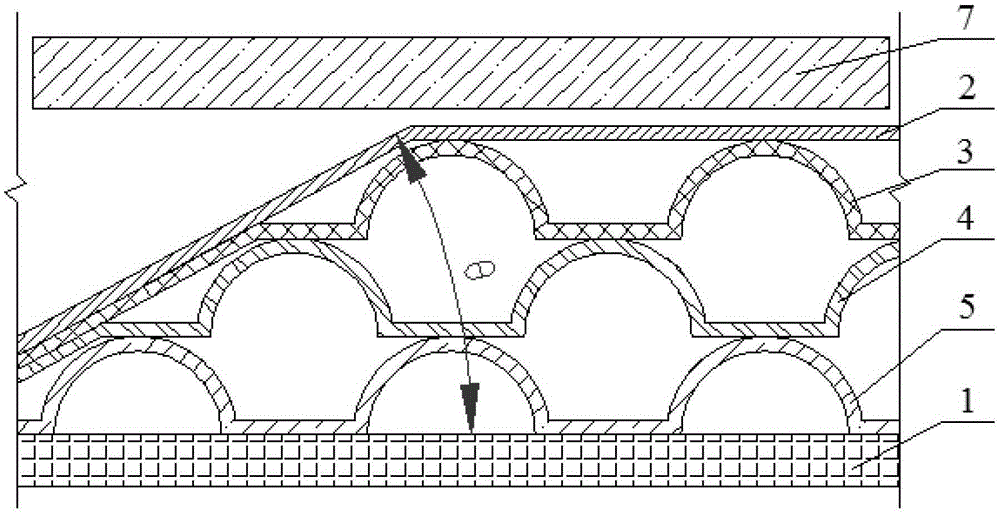

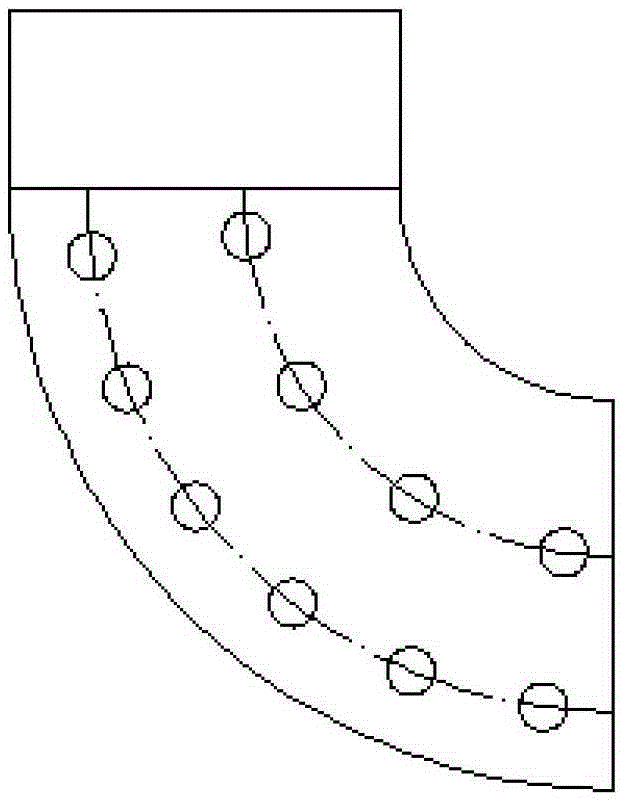

[0024] see figure 1 As shown, the present invention provides a multilayer bubbling foil dynamic pressure gas thrust bearing, comprising a bearing housing 1 and a shaft with a rotor thrust plate 7 arranged in the bearing housing 1, the bearing housing 1 and the rotor thrust plate Several groups of elastic elements with the same structure are arranged between the plates 7, and the elastic elements are evenly arranged along the circumference of the bearing seat 1; The flat foil foil 2 between the blade and the rotor thrust plate 7, the flat foil foil 2 is attached to the elastic bubbling foil; each layer of bubbling foil is provided with a bubbling protrusion; one end of the elastic element passes through the positioning element 6 is fixed on the bearing seat 1, and the other end is free so that it has space for deformation and sliding. Specifically, the positioning el...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com