Large-stroke micro-drive precision two-dimensional worktable

A large-stroke, micro-drive technology, applied in the direction of manufacturing tools, large fixed members, metal processing equipment, etc., can solve the problems of small strokes of flexible hinges, unfavorable workbench performance, hysteresis of piezoelectric ceramics, etc., to achieve large displacement range and output The effect of strong force and strong applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

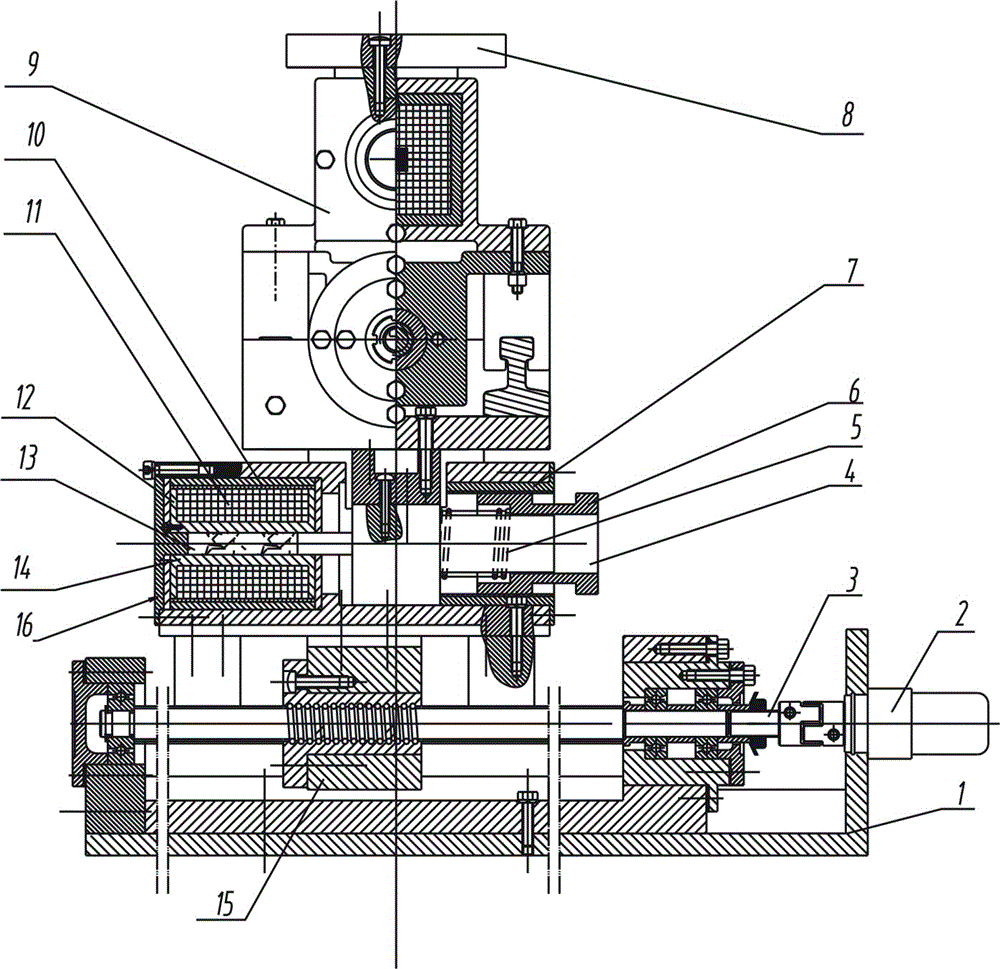

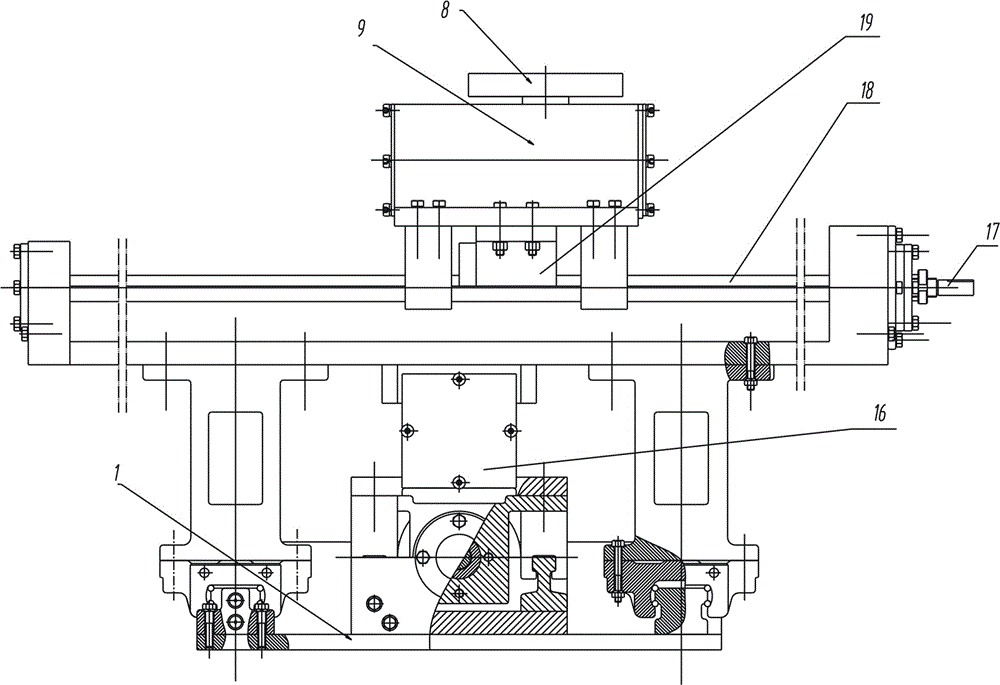

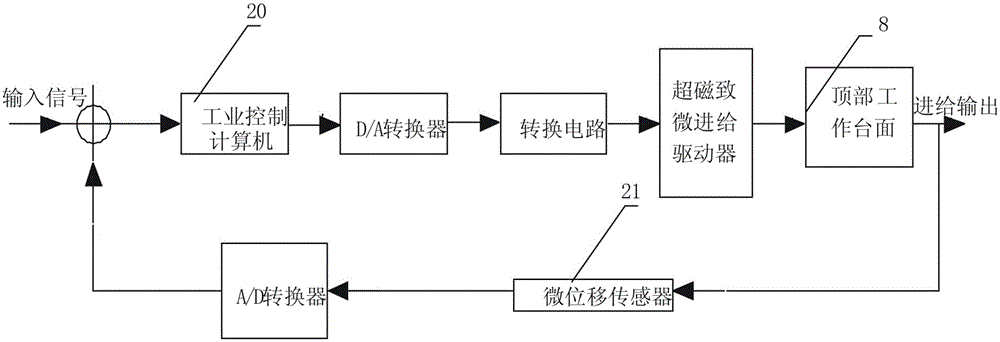

[0025] For a better understanding of the present invention, below in conjunction with the attached Figure 1-3 The technical solution of the present invention will be further described with specific embodiments.

[0026] Such as figure 1 , 2 The large-stroke micro-drive precision two-dimensional workbench shown is mainly composed of a base, X and Y two-way feeding devices perpendicular to each other in the two-dimensional plane, and a top working table 8 on the top of the feeding device, and the Y-direction feeding device Set on the X-direction feed device. The X-direction feed device includes the X-direction large-stroke feed device and the X-direction micro-feed device 16, and the Y-direction feed device includes the Y-direction large-stroke feed device and the Y-direction micro-feed device 9; the Y-direction large-stroke feed device 9; The device is arranged on the X-direction micro-feeding device 16 and can move with the feeding action of the X-direction micro-feeding d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com