Chassis drive system control method and device

A control method and a technology of a control device, which are applied in the field of vehicles, can solve problems such as driver misoperation and flameout, and achieve the effects of reducing operator fatigue, better energy-saving performance, and improving the degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Embodiments of the invention are described in detail below, but the invention can be practiced in many different ways as defined and covered by the claims.

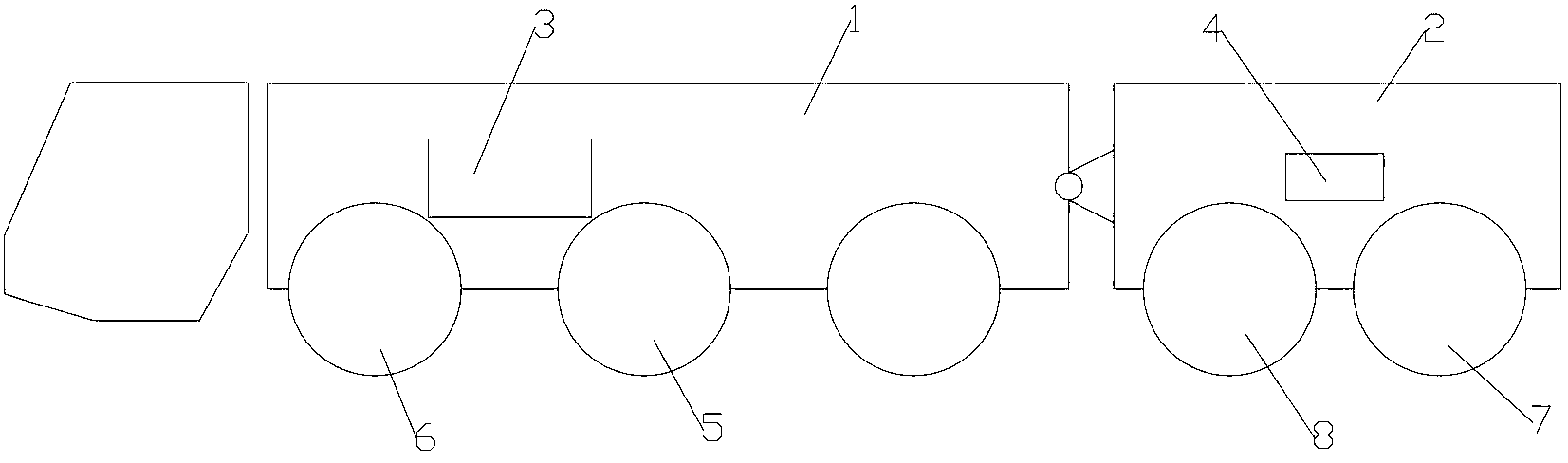

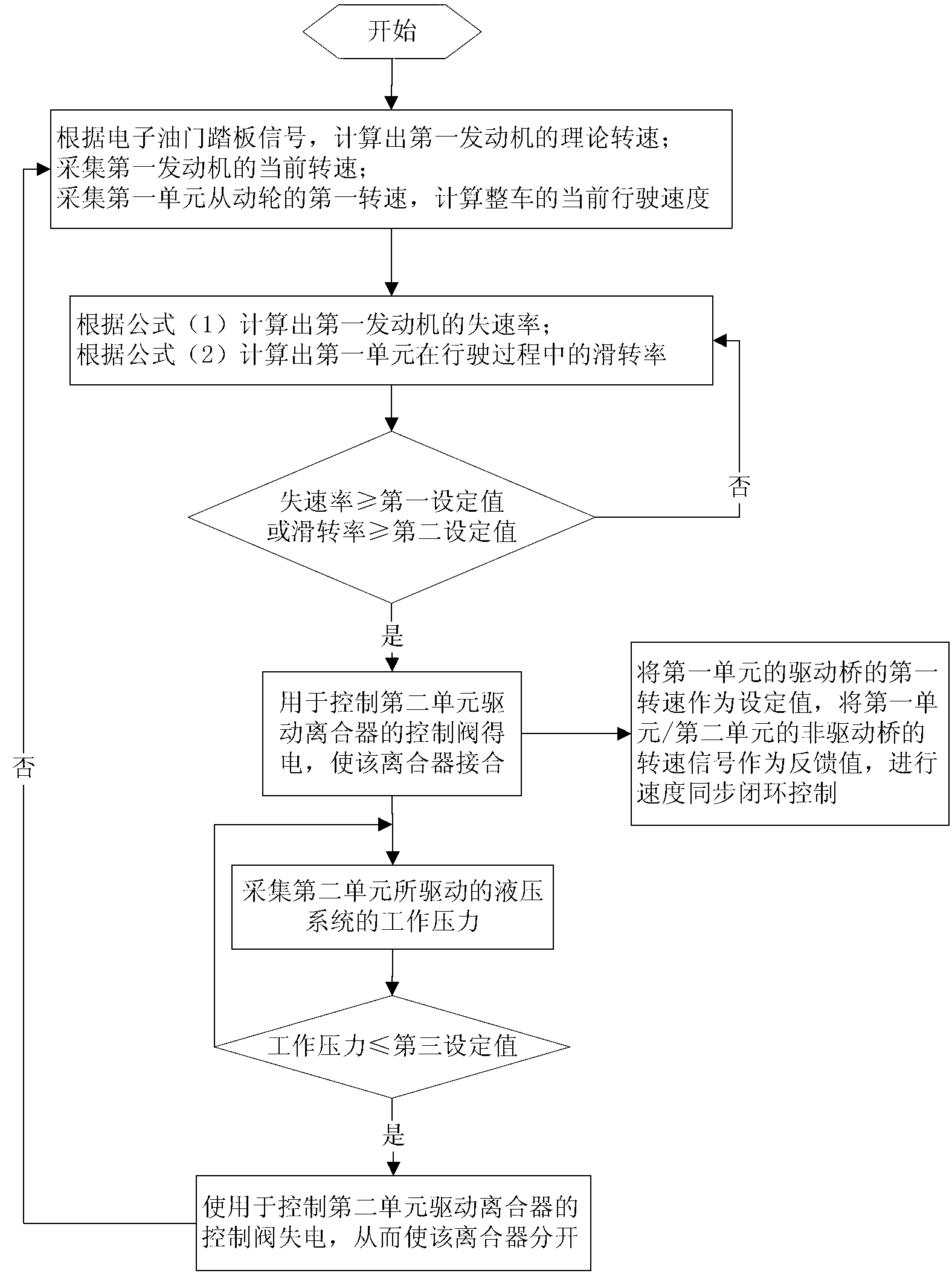

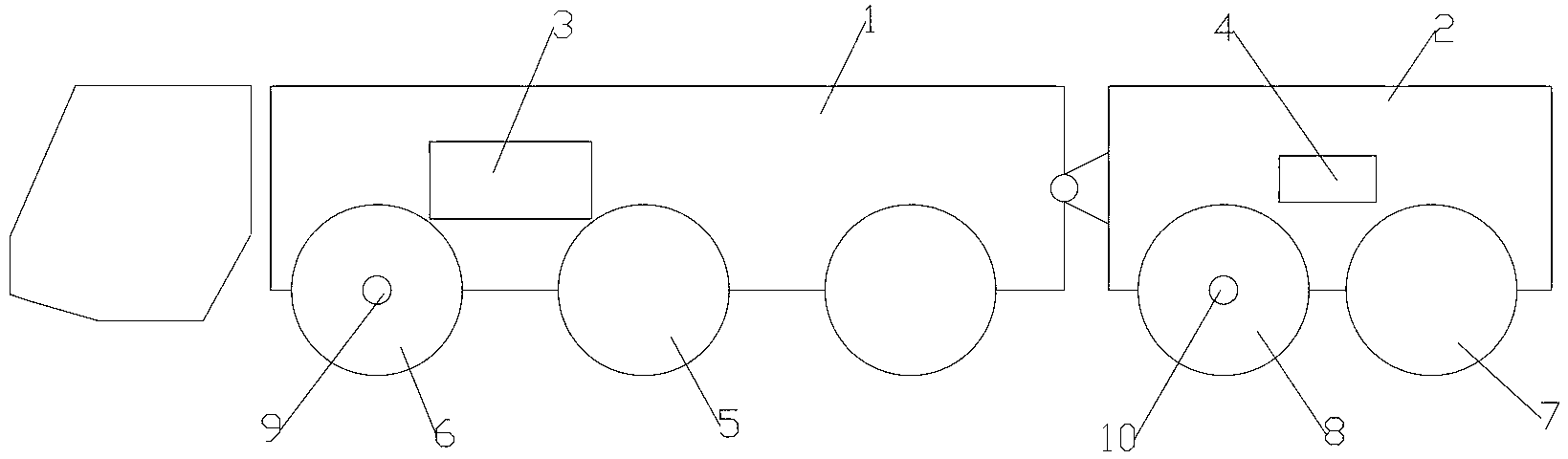

[0025] In some vehicles (such as super-large-tonnage all-terrain cranes, etc.), because the engine manufacturer does not have a matching engine, or because the matching engine installation size is limited, or for energy-saving considerations, dual-power (first engine and the second engine), in which the main power source (the first engine) is arranged in the first unit for driving the vehicle on a smooth road, and the auxiliary power source (the second engine) is arranged in the second unit, It is used to provide auxiliary power for the first unit in the uphill working condition of the whole vehicle or on rough roads. The present invention provides an automatic control method and device for the realization of separation and separation of main and auxiliary power sources and speed synchronization according to the ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com