Semisteel steelmaking method

A molten steel and converter technology, applied in the manufacture of converters, etc., can solve the problems of slow slag incoming, high iron content in final slag, and difficulty in slag melting, and achieve the effects of reducing costs and solving slow incoming slag

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

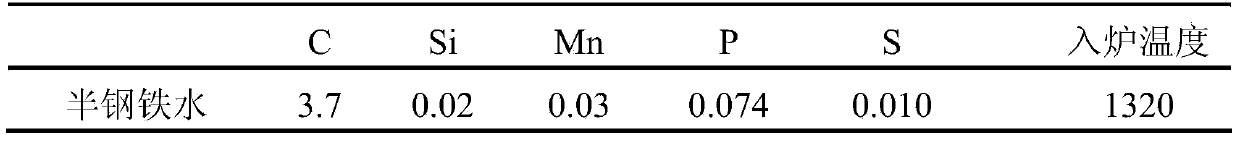

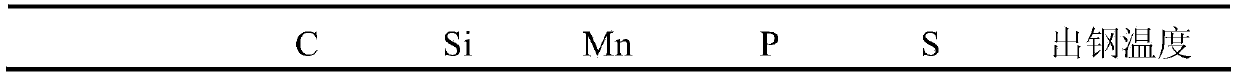

[0030] The steel for SS(R) rails is smelted on a 120t converter in a steel factory. The actual weight of half-steel molten iron in the furnace is 138.8t, and the weight of the steel is 140.17t. The actual oxygen blowing volume is 6210m 3 . Dolomite is added after steel is tapped from the converter and the furnace is protected by slag splashing. The composition and temperature of molten iron and steel entering the furnace are shown in Table 1.

[0031] Table 1 Composition (%) and furnace temperature (°C) of molten iron and steel entering the furnace

[0032]

[0033]Dolomite is added after the converter is tapped and slag splashed to protect the furnace. The amount of dolomite added is 32kg / t steel. After waiting for 10 minutes, the semi-steel molten iron is loaded to start oxygen blowing steelmaking. After the semi-steel converter oxygen blowing starts Add active lime and slagging agent to the converter within 2 minutes, wherein the amount of active lime (containing 85% ...

example 2

[0040] Steel for SS(R) rails is smelted on a 120t converter in a steel plant. The actual weight of molten iron and steel entering the furnace is 135t, the weight of the steel is 136.54t, and the actual oxygen blowing volume is 6400m 3 . Dolomite is added after steel is tapped from the converter and the furnace is protected by slag splashing. The composition and temperature of molten iron and steel entering the furnace are shown in Table 3.

[0041] Table 3 Composition (%) and furnace temperature (°C) of molten iron and steel entering the furnace

[0042]

[0043] Dolomite is added after the converter is tapped and slag splashed to protect the furnace. The amount of dolomite added is 31kg / t steel. After waiting for 10 minutes, the semi-steel molten iron is loaded to start oxygen blowing steelmaking, and the oxygen blowing in the semi-steel converter starts. Add active lime and slagging agent to the converter within the last 2 minutes, wherein the adding amount of active li...

example 3

[0049] 45 types of steel are smelted on a 120t converter in a steel factory. The actual weight of molten iron and steel entering the furnace is 134t, the weight of the steel is 134.42t, and the actual oxygen blowing volume is 6600m 3 . Dolomite is added after steel is tapped from the converter and the furnace is protected by slag splashing. The composition and temperature of molten steel in the furnace are shown in Table 5.

[0050] Table 5 Composition (%) and furnace temperature (°C) of molten iron and steel entering the furnace

[0051]

[0052]

[0053] Dolomite is added after the converter is tapped and slag splashed to protect the furnace. The amount of dolomite added is 30kg / t of steel. After waiting for 10 minutes, the semi-steel molten iron is loaded to start oxygen blowing steelmaking, and the oxygen blowing in the semi-steel converter starts. Add active lime and slagging agent to the converter within the last 2 minutes, wherein the adding amount of active lim...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| burnout rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com