Glasses

A glasses and split ring technology, applied in glasses/goggles, optics, instruments, etc., can solve the problems of difficult to replace parts, high manufacturing cost, and unfavorable widespread use by consumers, and achieve the effect of simplified structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

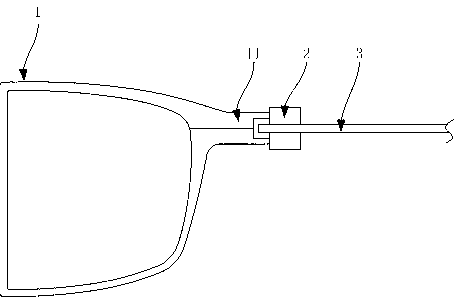

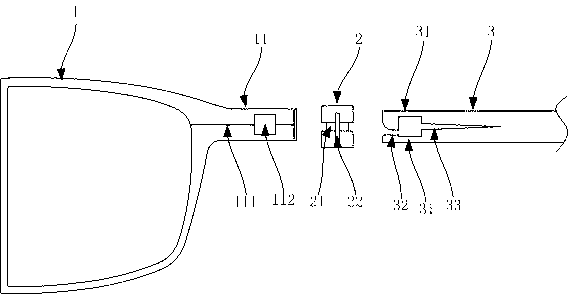

[0028] Such as Figure 1 to Figure 7 Shown, a kind of glasses, comprise Zhuang head 11, foot plate 3 and connector 2; Zhuang head 11 has a through hole 112; Foot plate 3 has a split ring 31, connector 2 has a rotating post 21 and a groove 22; Zhuang The end of the head 11 is correspondingly inserted into the groove 22 , and the split ring 31 is sheathed on the rotating column 21 and passes through the through hole 112 . The head 11 is directly embedded in the connector 2, the split ring 31 of the foot plate 3 is sleeved on the rotating column 21 of the connector 2, and passes through the through hole 112 of the head 11 to realize the hinge function and the structure is simplified.

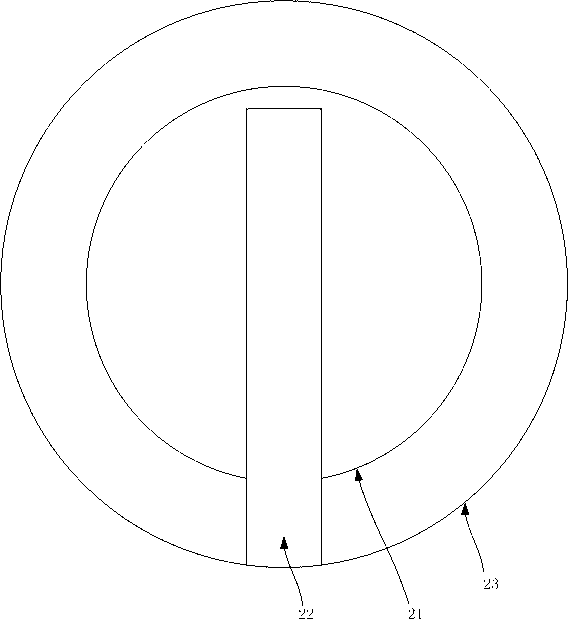

[0029] The section of the rotary column 21 is circular, and correspondingly, the inner frame of the split ring 31 is circular. When the rotating column 21 is a cy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com