Clamping tool for trimming wing leading edge covering

A technology for clamping tooling and leading edge skin, applied in workpiece clamping devices, manufacturing tools, etc., to achieve the effect of increasing the adjustment range, significant economic benefits, and reducing design and manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] In the following detailed description of the preferred embodiment, reference is made to the accompanying drawings which form a part hereof. The accompanying drawings show, by way of example, specific embodiments in which the invention can be practiced. The illustrated embodiments are not intended to be exhaustive of all embodiments in accordance with the invention. It is to be understood that other embodiments may be utilized and structural or logical changes may be made without departing from the scope of the present invention.

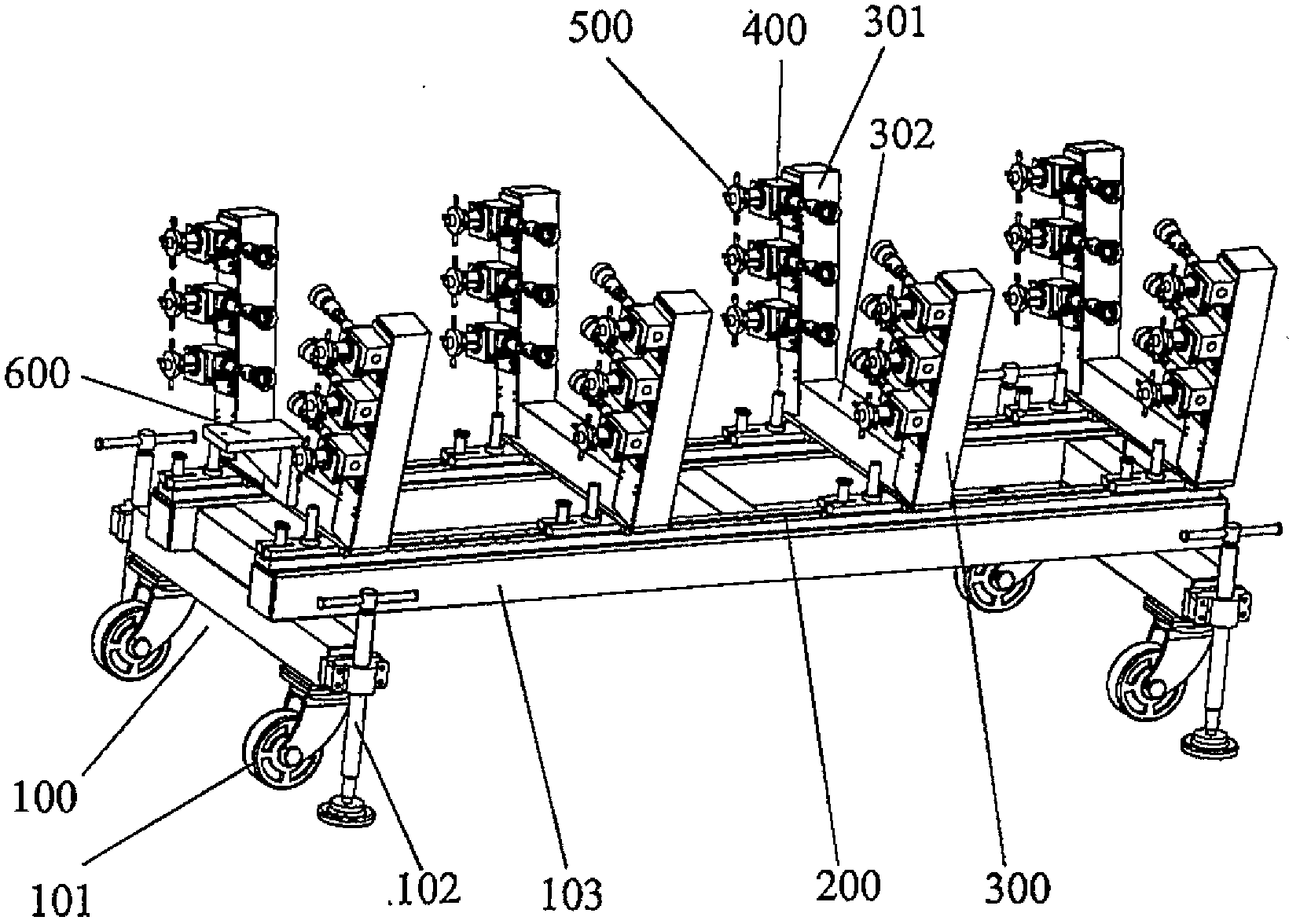

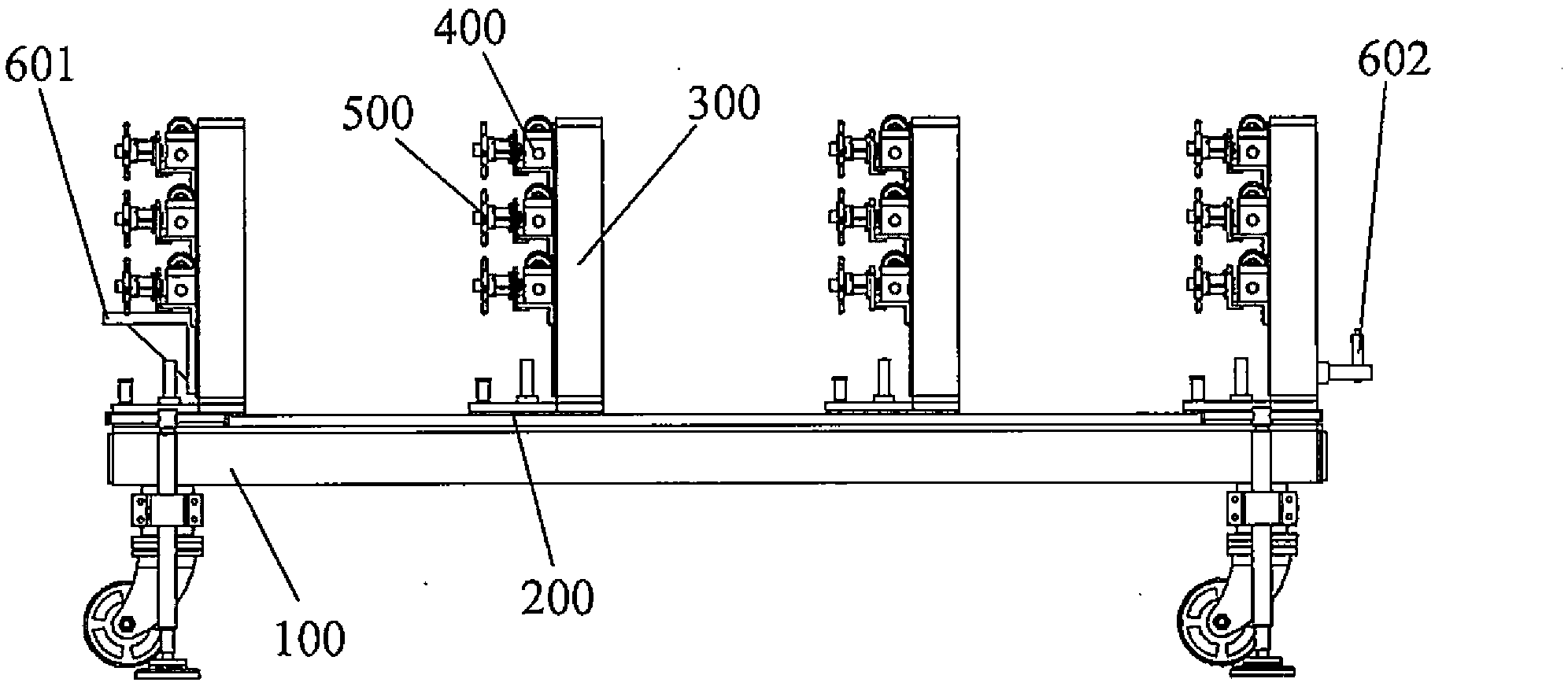

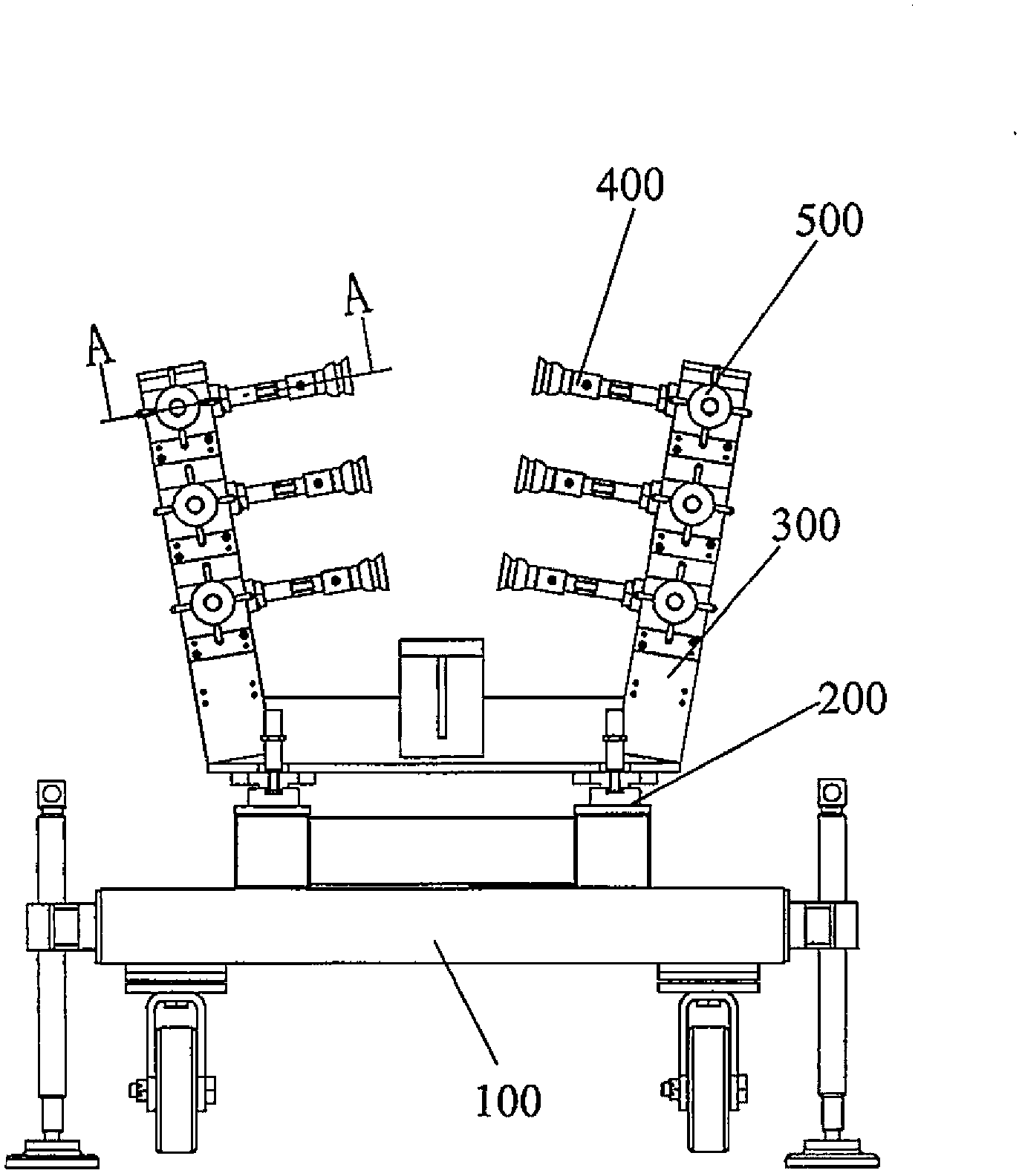

[0053] see Figure 1 to Figure 6 As shown, according to the present invention, the clamping tool for wing-type leading edge skin trimming includes a base 100, two sliding rail pairs 200, a plurality of U-shaped arms 300, a plurality of flexible clamping assemblies, and a plurality of quick positioning device 500 and skin positioner 600. Wherein, the sliding rail pair 200 is arranged on the base; each U-shaped arm 300 has two arm portions 30...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com