Prefabricated bridge concrete rainproof mobile pouring trolley

A concrete and trolley technology, applied in the direction of manufacturing tools, auxiliary molding equipment, ceramic molding machines, etc., can solve the problems of concrete quality impact and troubles, and achieve the effect of reducing equipment investment, flexible transfer, and good rainproof function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The specific embodiment of the present invention will be further described in conjunction with the accompanying drawings.

[0032] 1 Prefabricated bridge concrete rainproof mobile pouring trolley structure

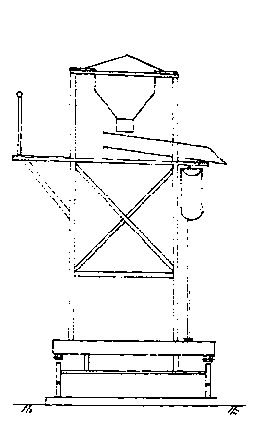

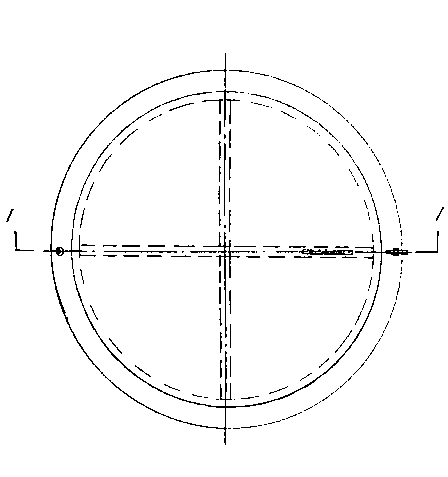

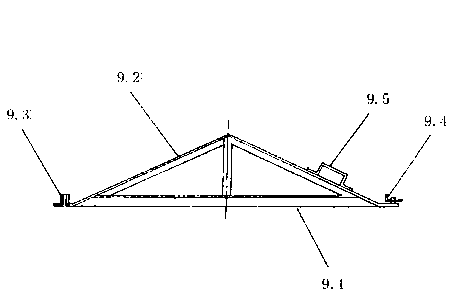

[0033] The prefabricated bridge concrete rainproof mobile pouring trolley consists of five parts: traveling trolley, support platform, receiving hopper, fixed chute, and rotating chute. See attached figure 1 .

[0034] 1. Walking trolley

[0035] The traveling trolley is an electric track flatbed, driven by batteries. Walking on the track laid by the steel rails inside the bridge formwork, it can unload materials between each segment in the length direction of the bridge. There are two rail clamps at each end of the trolley. The rail clamp is a pincer structure. It consists of two splints and an adjusting screw. There are connecting screw holes on the top of the splint, and the rail clamp is installed on the horizontal rotating shaft under the traveling t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com