Preparation method of physical model test device for large-cycle accelerated loading of railway subgrade

A physical model, a technology of railway subgrade, applied in the direction of using repetitive force/pulse force to test the strength of materials, etc., which can solve the difficulty in simulating changes in the dynamic performance of transportation infrastructure, uncontrollable geological conditions and environmental conditions, and inability to model the track and subgrade. Realize problems such as reproducibility, and achieve the effects of real-time monitoring, easy burying, and simple test operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

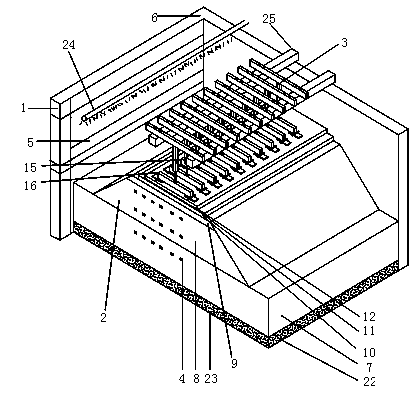

[0042] The present invention will be further described below in conjunction with drawings and embodiments. The preparation process of device among the present invention is as follows:

[0043] 1. The construction of model test chamber 1: such as figure 1 As shown, model test chamber 1: a rectangular steel structure model tank composed of main steel structure beams and columns 5 and main structure side steel plates 6. The specific size can be determined according to the required model size. In this example, the size used is 15m×long Width 5m x height 6m;

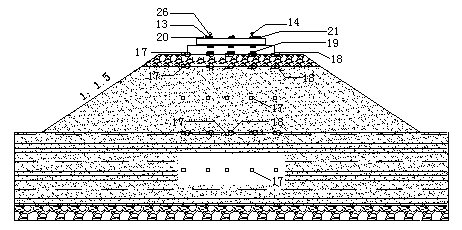

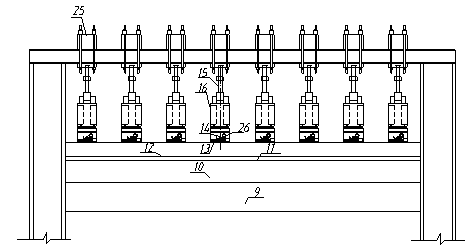

[0044] 2. The construction of the high-speed railway ballastless track subgrade model 2 and the monitoring system 4: lay gravel and sand cushion 22 on the bottom plate of the model test box 1. On the gravel and sand cushion layer 22, the foundation 7, the bottom layer of the foundation bed 8 and the surface layer of the foundation bed 9 are layered. During the filling process, the middle thickness of the foundation 7, the ju...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com