System for kinetic model test of ballastless track subgrade of high-speed railway

A dynamic model, ballastless track technology, applied in the directions of roads, tracks, roads, etc., can solve the problems of uncontrollable geological conditions and environmental conditions, and the inability to repeat the production of track and roadbed models, achieving easy burial and simple test operations. , Monitoring the overall effect of the system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

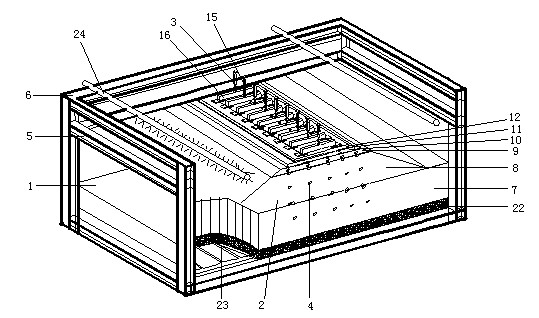

[0030] Such as figure 1 As shown, the system consists of a model test chamber 1, a high-speed railway ballastless track subgrade model 2, an excitation system 3 and a monitoring system 4; among them:

[0031] 1) Model test chamber 1: a rectangular steel structure model tank composed of main steel structure beams and columns 5 and main structure side steel plates 6, with dimensions of 15m long x 5m wide x 6m high;

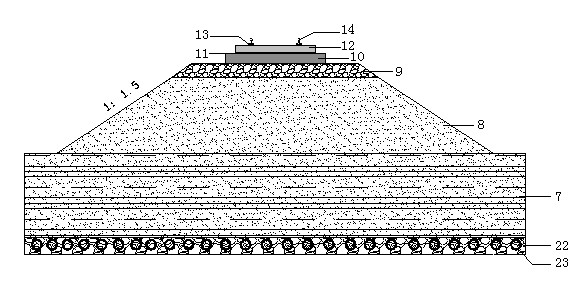

[0032] 2) High-speed railway ballastless track subgrade model 2: gravel and sand cushion 22, foundation 7, subgrade bed bottom layer 8, subbed surface layer 9, concrete base 10, CA Mortar 11, track plate 12, fastening system 13 and two steel rails 14, such as figure 2 As shown; two rails 14 are connected on the track plate 12 by fastener system 13, and the bottom layer 8 of the bed and the surface layer 9 of the bed form a trapezoid with a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com