Crane provided with folding arm and beams

A crane and girder technology, which is applied in the field of folding arm girder cranes, can solve problems such as reducing the reliability of the crane, and achieve the effect of increasing the reliability of the system and ensuring the stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with specific embodiments and accompanying drawings, but the protection scope of the present invention should not be limited thereby.

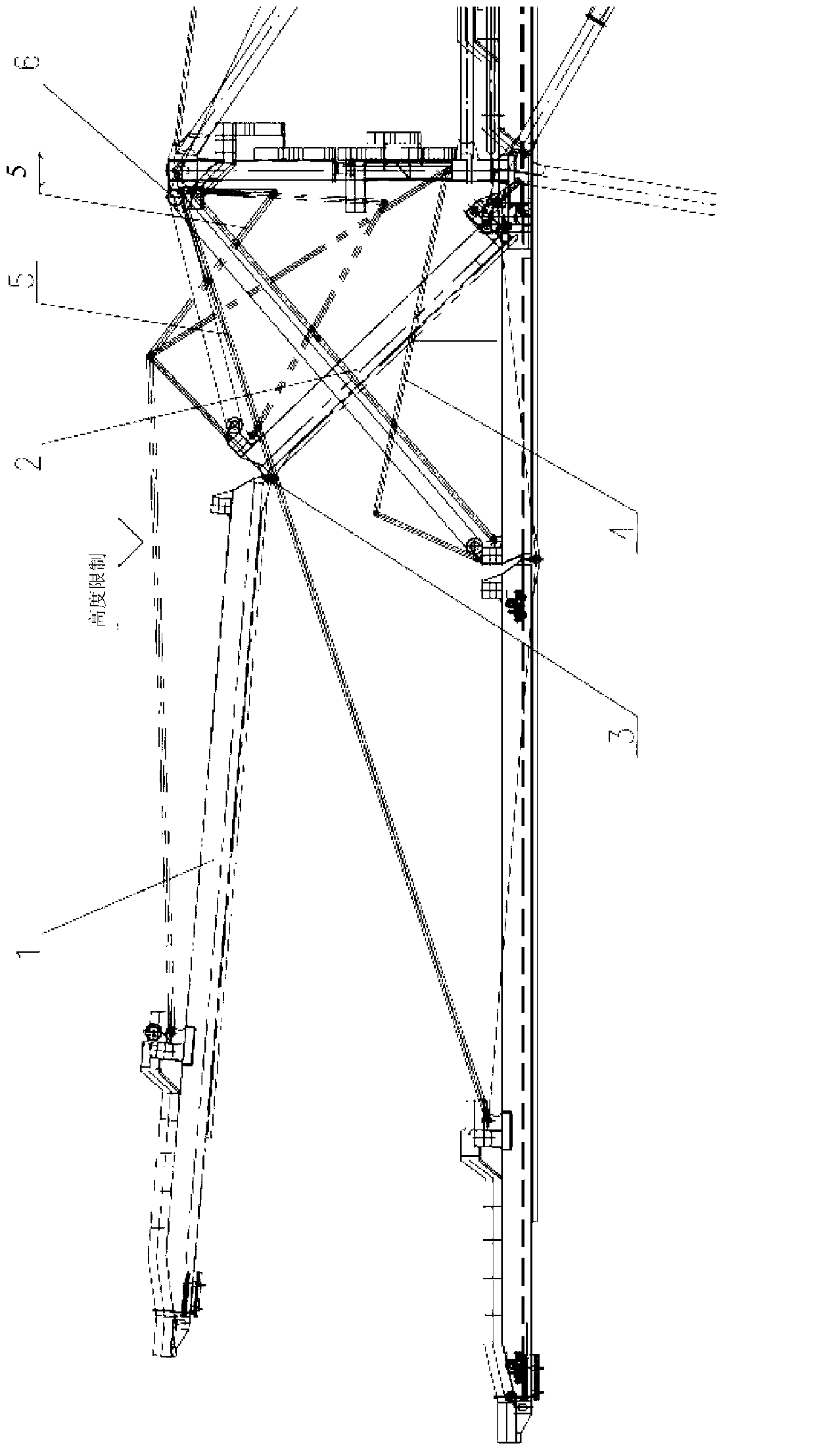

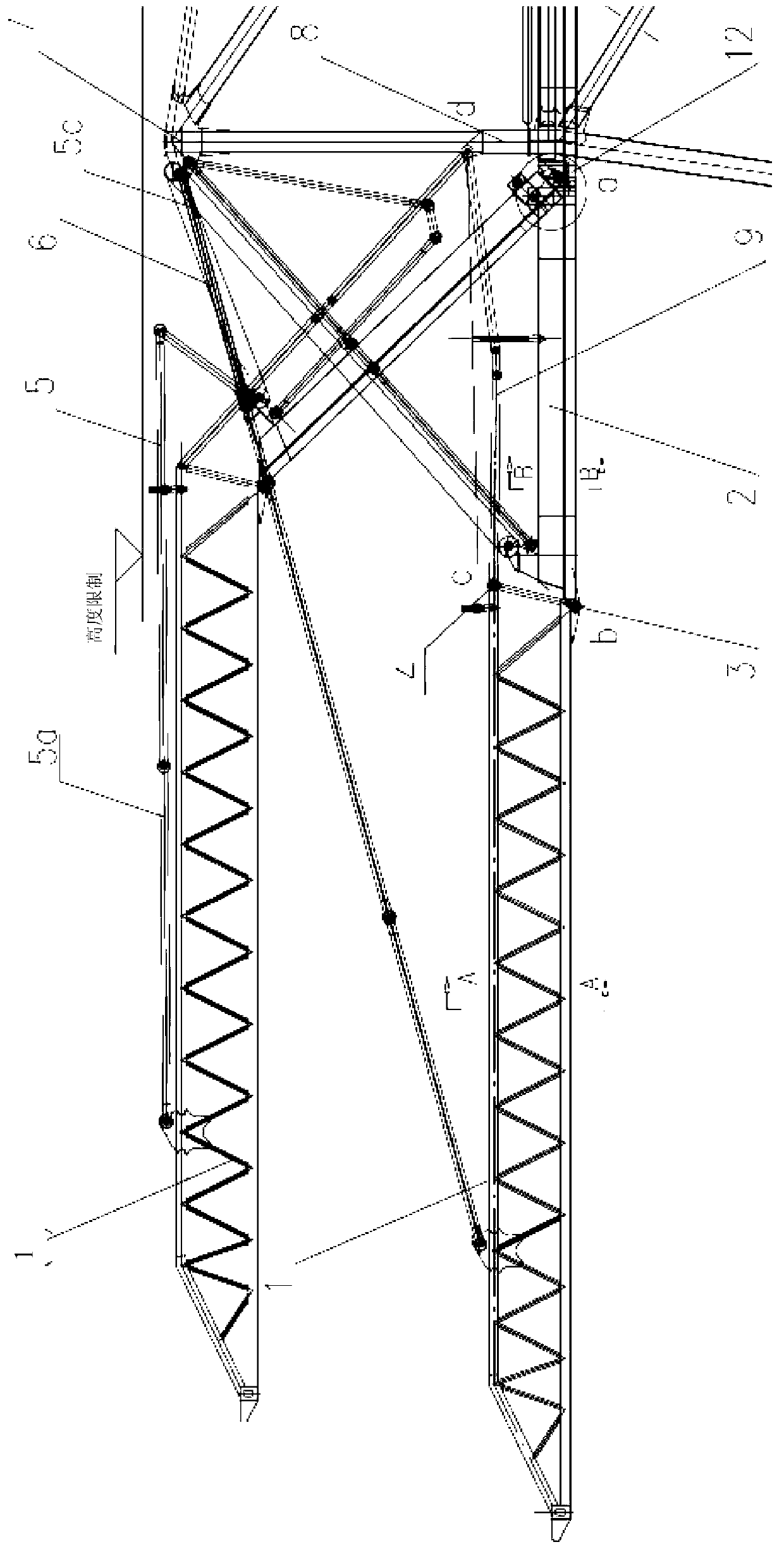

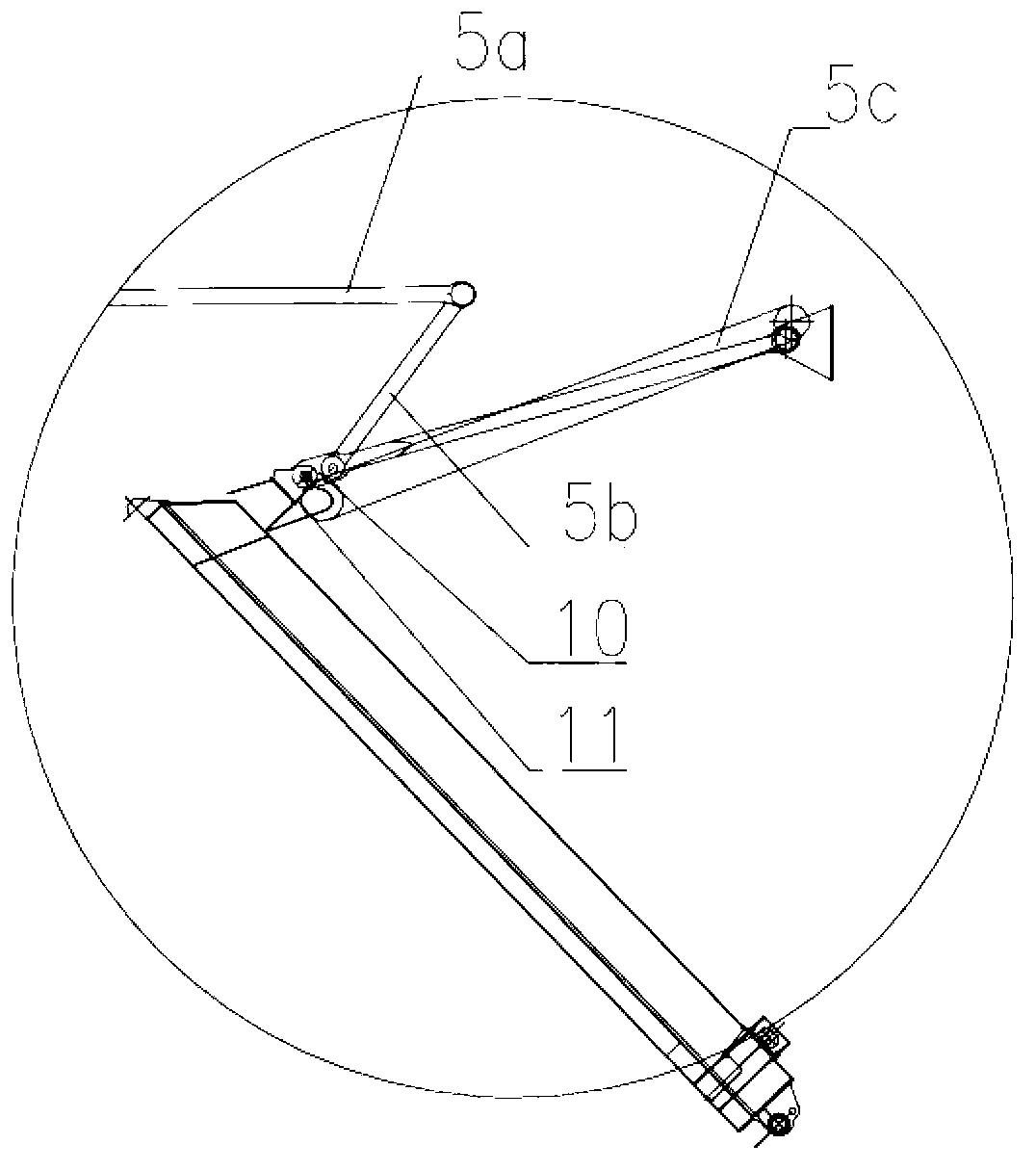

[0030] refer to figure 2 , in this embodiment, the folding arm girder of the folding arm girder crane includes the folding arm inner section girder 2 and the folding arm outer girder 1 connected thereto. In addition, the folding arm girder crane of this embodiment also includes a working tie rod system 5, a pitching wire rope Winding system 6, sea-side trapezoidal frame 7, sea-side upper beam 8, pitching gooseneck pull rod 9. It should be noted, figure 2 The figure shows the two states of the folding arm girder, the pitch and the supine.

[0031] Wherein, the outer girder 1 of the folding arm is a truss structure, and the inner girder 2 of the folding arm can still maintain a double-box trapezoidal girder structure. While ensuring the rigidity of the girder, the t...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap