Linkage device for bridges

A linkage device and bridge technology, applied in bridges, bridge parts, bridge construction, etc., can solve the problems of long production and processing cycle, high price, leakage, etc., achieve good elasticity and damping, mature technology, and convenient adjustment Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

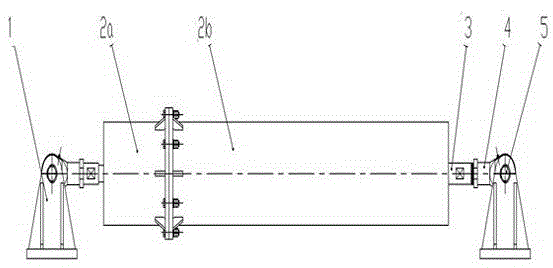

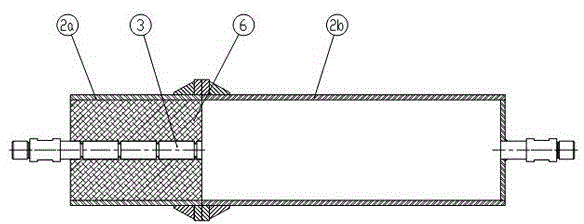

[0023] Embodiment 1: as figure 1 , 2 As shown, a linkage device for a bridge includes a detachably butted rubber casing 2a and a connecting cylinder 2b, the rubber casing 2a is filled with an elastomer material 6 and a connecting shaft 3 is arranged axially in the center , the elastomer material 6 is firmly bonded to the inner wall of the rubber casing 2a and the surface of the connecting shaft 3, and the connecting shaft 3 protrudes from the left end of the rubber casing 2a to thread the joint bearing 4, and the joint bearing 4 rotates through the pin shaft 5 Connected to the connecting lug 1, the right end of the connecting cylinder 2b is fixedly connected to the connecting shaft 3, the right end of the connecting shaft 3 is threaded to the joint bearing 4, and the joint bearing 4 is rotatably connected to the connecting lug 1 through the pin shaft 5.

[0024] The rubber-covered cylinder 2a and the connecting cylinder 2b are respectively provided with flanges at the ends, a...

Embodiment 2

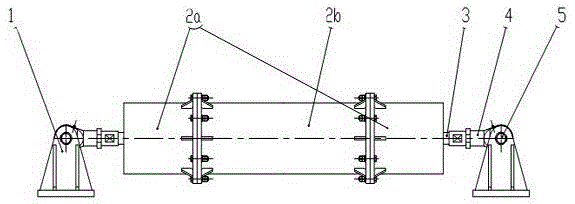

[0025] Embodiment 2: as image 3 , 4 As shown, a linkage device for a bridge includes a connecting cylinder 2b and two rubber casings 2a detachably butted at both ends of the connecting cylinder 2b, each rubber casing 2a is filled with an elastomer material 6 and in the center A connecting shaft 3 is arranged in the axial direction, and the elastomer material 6 is firmly bonded to the inner wall of the rubber casing 2a and the surface of the connecting shaft 3, and the connecting shaft 3 extends out of the left end of the rubber casing 2a on the left and the rubber covering on the right. The right end of the cylinder 2a is then threaded on the protruding end of the joint bearing 4, and the joint bearing 4 is rotatably connected to the connecting lug 1 through the pin shaft 5.

[0026] Both ends of the connecting cylinder 2b and one end of the two rubber-coated cylinders 2a are provided with flanges, and bolts are used to fix the flanges on the ends of the connecting cylinder ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com