Positioning bolt

A technology of positioning bolts and bolts, which is applied in the directions of engine components, mechanical equipment, valve devices, etc., can solve the problems of lax valve closing, low precision, over-position, etc., and achieve the effect of avoiding lax or over-positioning.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

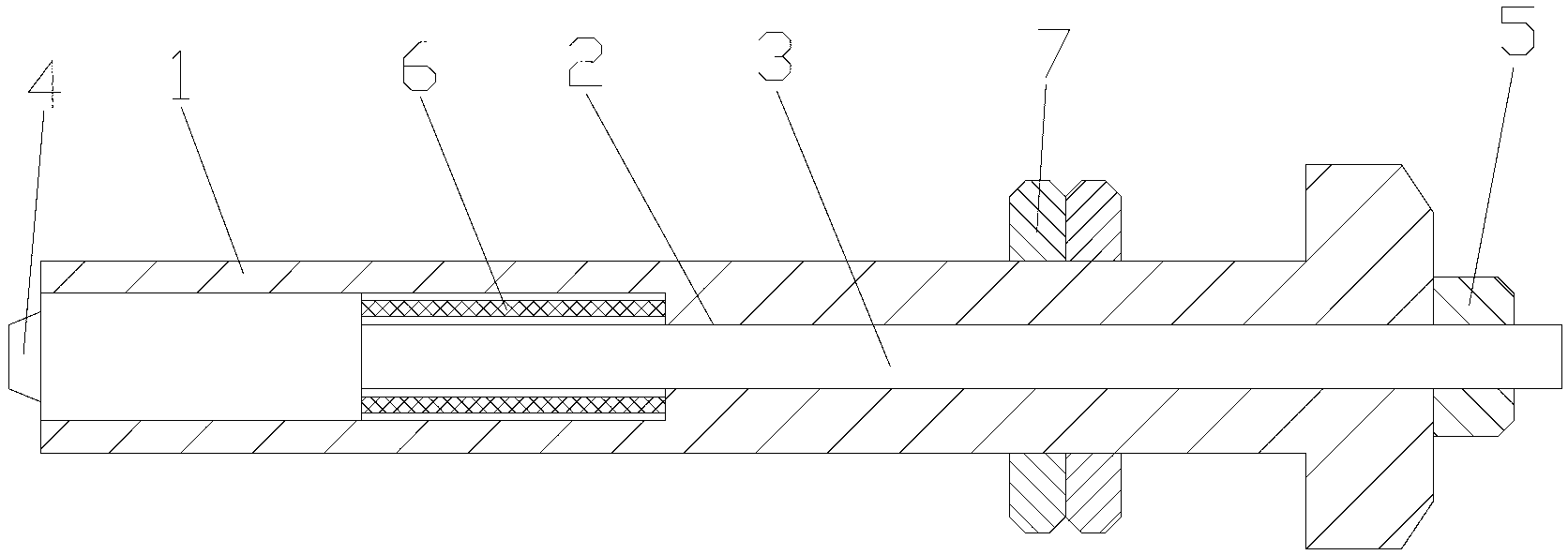

[0012] The present invention is described below in conjunction with accompanying drawing.

[0013] as attached figure 1 The shown positioning bolt of the present invention includes a bolt body 1, and a stepped hole 2 is opened in the bolt body 1; a thimble 3 matching the stepped hole 2 is provided in the stepped hole 2; The large-diameter end of the thimble 3 is flush with the tail end of the bolt body 1; the large-diameter end of the thimble 3 is provided with a boss 4; the boss 4 extends out of the bolt body 1; the small-diameter end of the thimble 3 Extend the head of the bolt body 1; the small diameter end of the thimble 3 is covered with an adjustment nut 5; the adjustment nut 5 is located outside the head of the bolt body 1 and is close to the head of the bolt body 1; the bolt body An elastic component is provided between 1 and the thimble 3; the elastic component is a spring 6; a self-locking nut 7 is also provided on the stem of the bolt body 1.

[0014] When the pos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com