Car carpet forming and punching integrated equipment

A car carpet and integrated technology, which is applied to vehicle parts, special positions of vehicles, transportation and packaging, etc., can solve the problems of large space occupation, large energy consumption, and high labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in further detail below in conjunction with accompanying drawing embodiment:

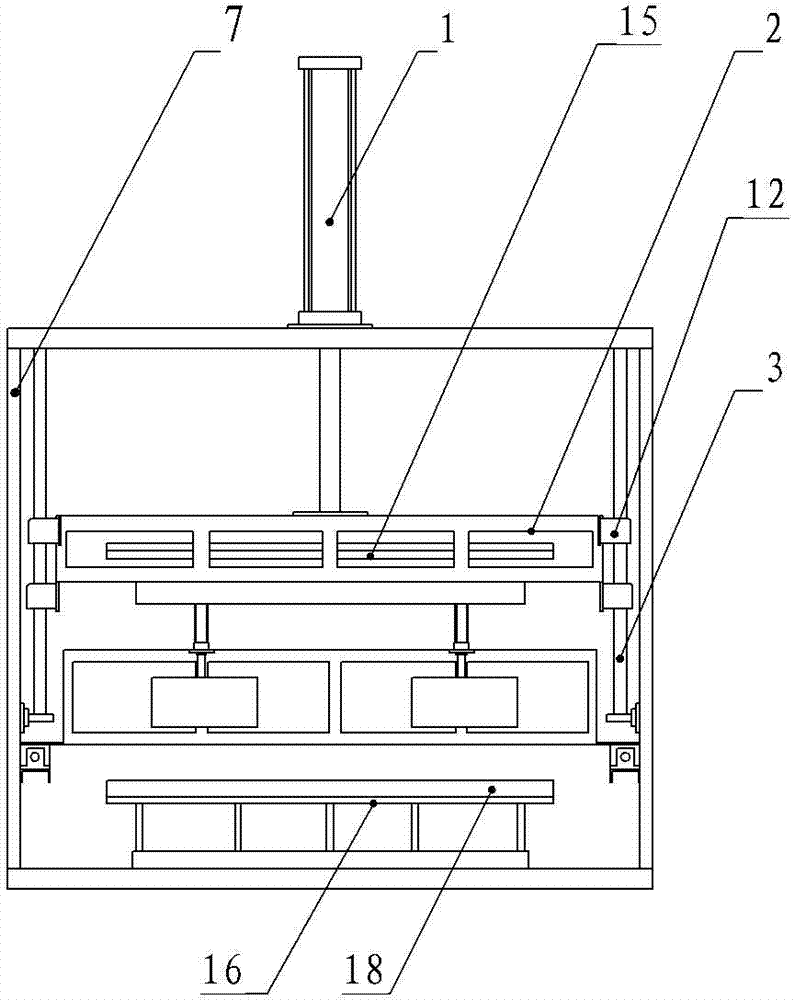

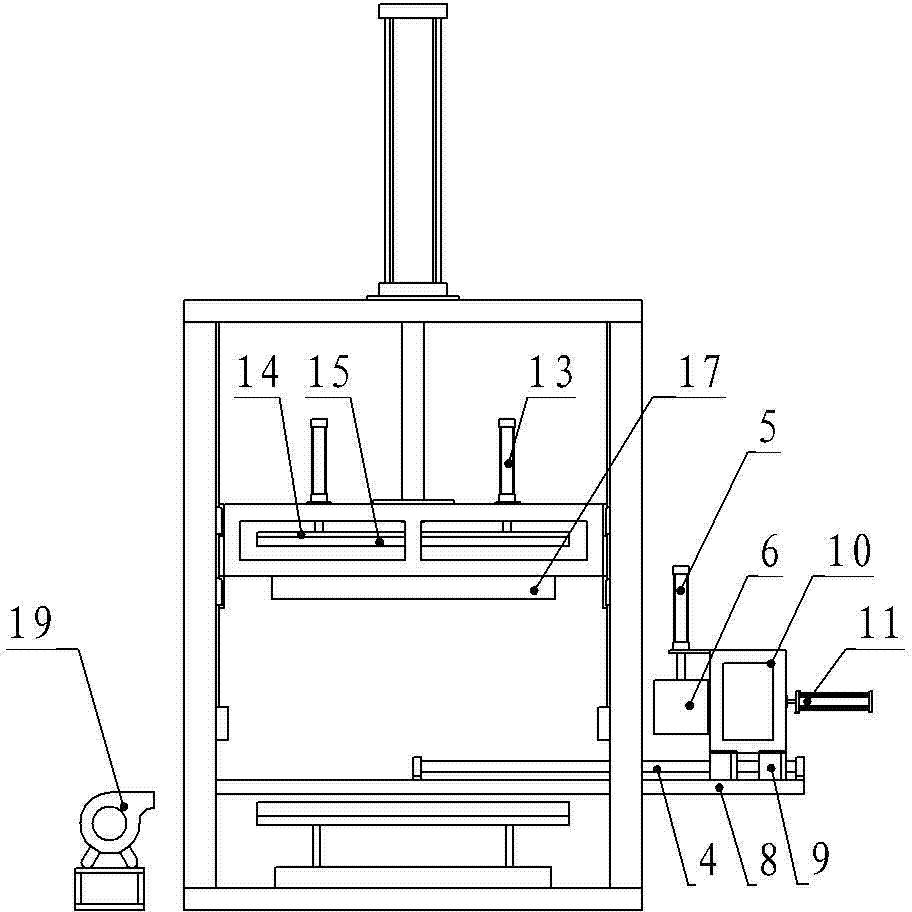

[0021] Such as Figure 1~2 The present embodiment shown, it comprises profiling device, heating device, cooling device and blanking device, and profiling device is mainly made up of frame 7, upper moving beam 2, cylinder one 1, longitudinal guide column 3, longitudinal guide sleeve 12, Forming upper die 17, lower mold frame 16 and pressing lower die 18 are formed, frame 7 is a support with four columns and a cuboid structure of upper and lower beams, cylinder one 1 is fixed on the upper beam of frame 7, and its piston rod and The upper movable beam 2 is connected and fixed; the pressure type upper die 17 is fixed on the lower plane of the upper movable beam 2; four vertical guide columns 3 are fixed on the four columns of the frame 7, and eight vertical guide columns 3 are fixed on the four corners of the upper movable beam 2 A longitudinal guide sleev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com