Large vehicle shipping crawling ladder

A technology for climbing ladders and vehicles is applied in the field of large-scale vehicle delivery, which can solve the problems of restricting the development of large-scale vehicle user units, increasing transportation costs, and reducing delivery efficiency, and achieves the effect of avoiding difficulties in loading, quick installation and use, and convenient management.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] This embodiment will be described in detail below in conjunction with the accompanying drawings.

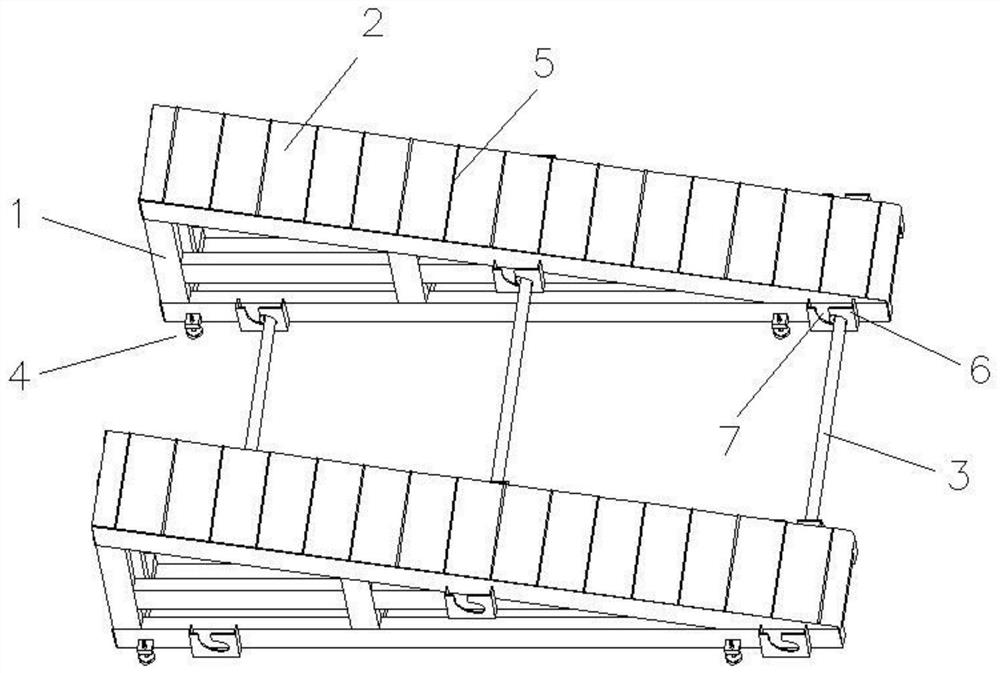

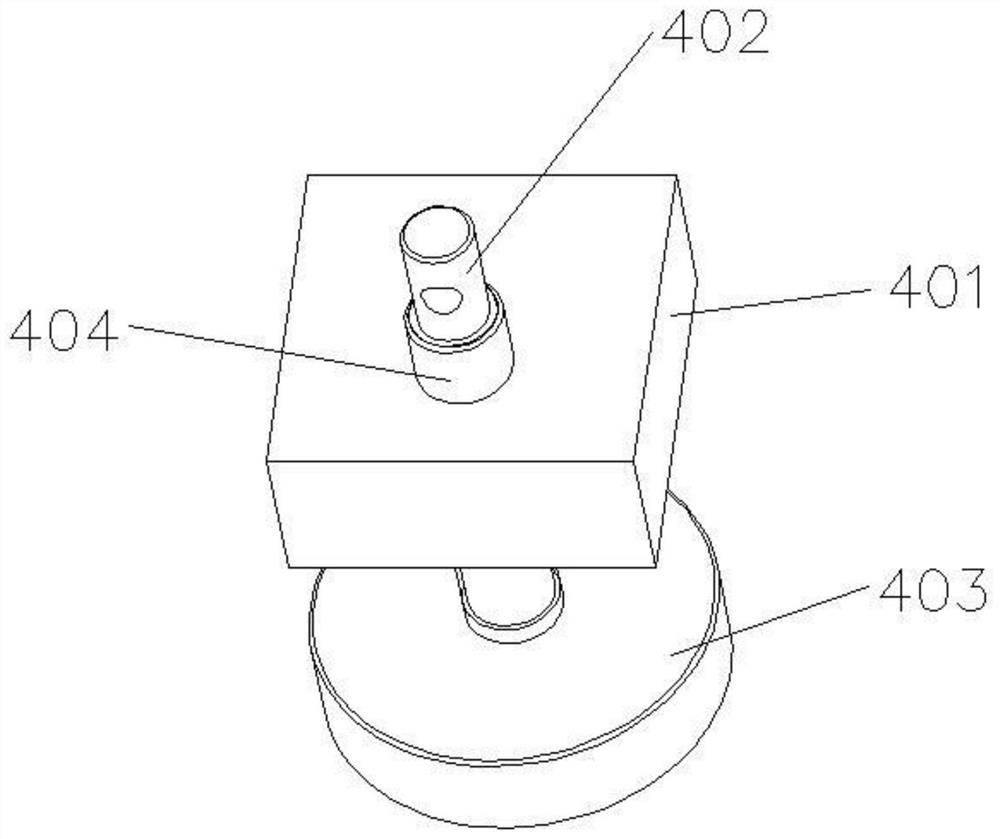

[0021] Such as figure 1 , figure 2 As shown in a large vehicle delivery ladder, the left and right projections of the ladder are triangles with the same shape and size, including a ladder frame 1, a supporting steel plate 2, a connecting rod 3, a leveling mechanism 4 and an anti-skid steel bar 5. The ladder frame 1 has Two groups, two sets of ladder skeletons 1 are arranged in parallel and connected by connecting rods 3. The ladder skeletons 1 are fixedly connected by beams, longitudinal beams and columns. The supporting steel plates 2 are fixed on the top of the ladder skeletons 1, and the supporting steel plates 2 The slope is 12°, the leveling mechanism 4 has multiple groups, symmetrically fixed on the bottom of both sides of the ladder frame 1, and the anti-skid steel bar 5 is evenly fixed on the supporting steel plate 3 parallel to the short side of the supporting s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com