Tray array one-time conveying device

A conveying device, a one-time technology, applied in the direction of conveyors, mechanical conveyors, transportation and packaging, etc., can solve the problems of time-consuming, insufficient loading and transportation efficiency, and achieve the effect of increasing loading efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

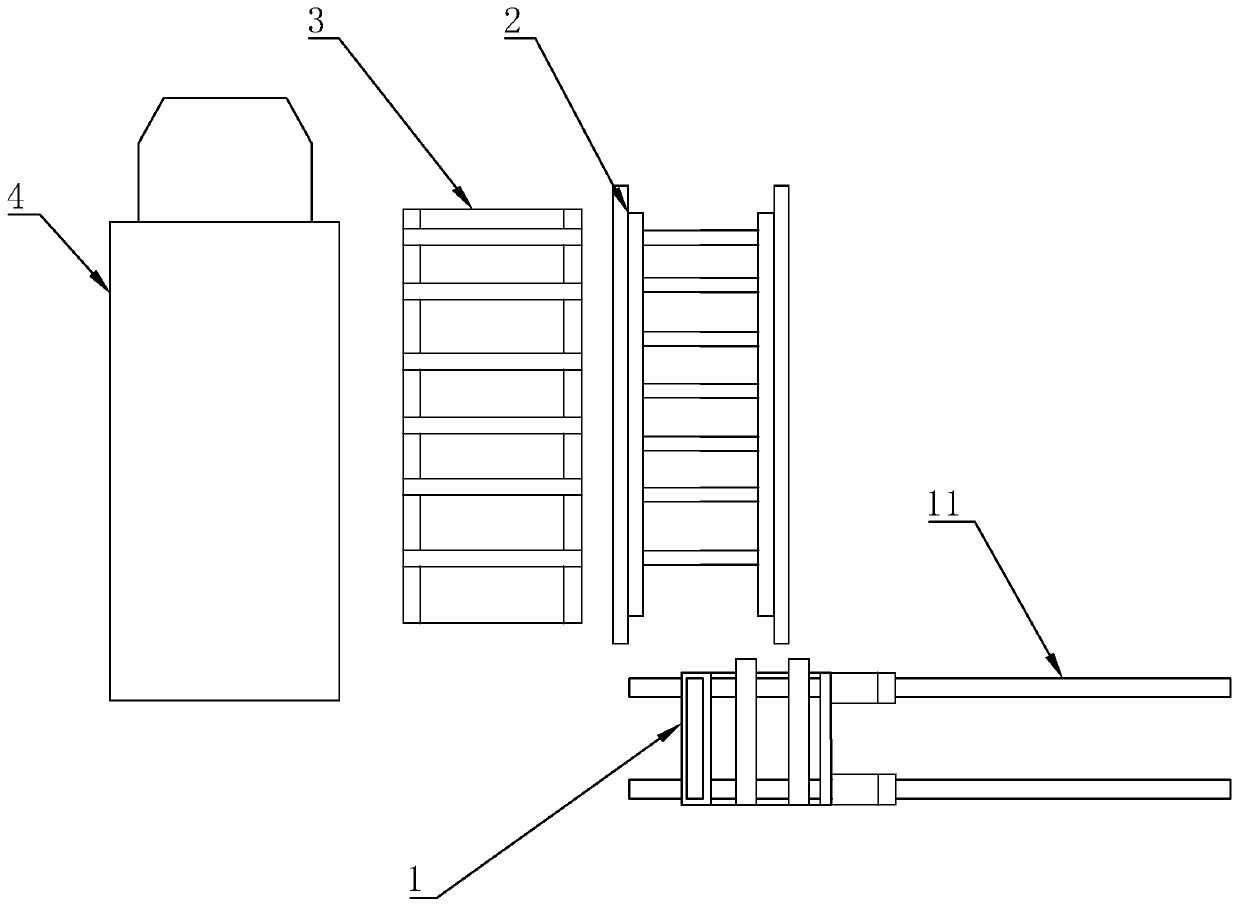

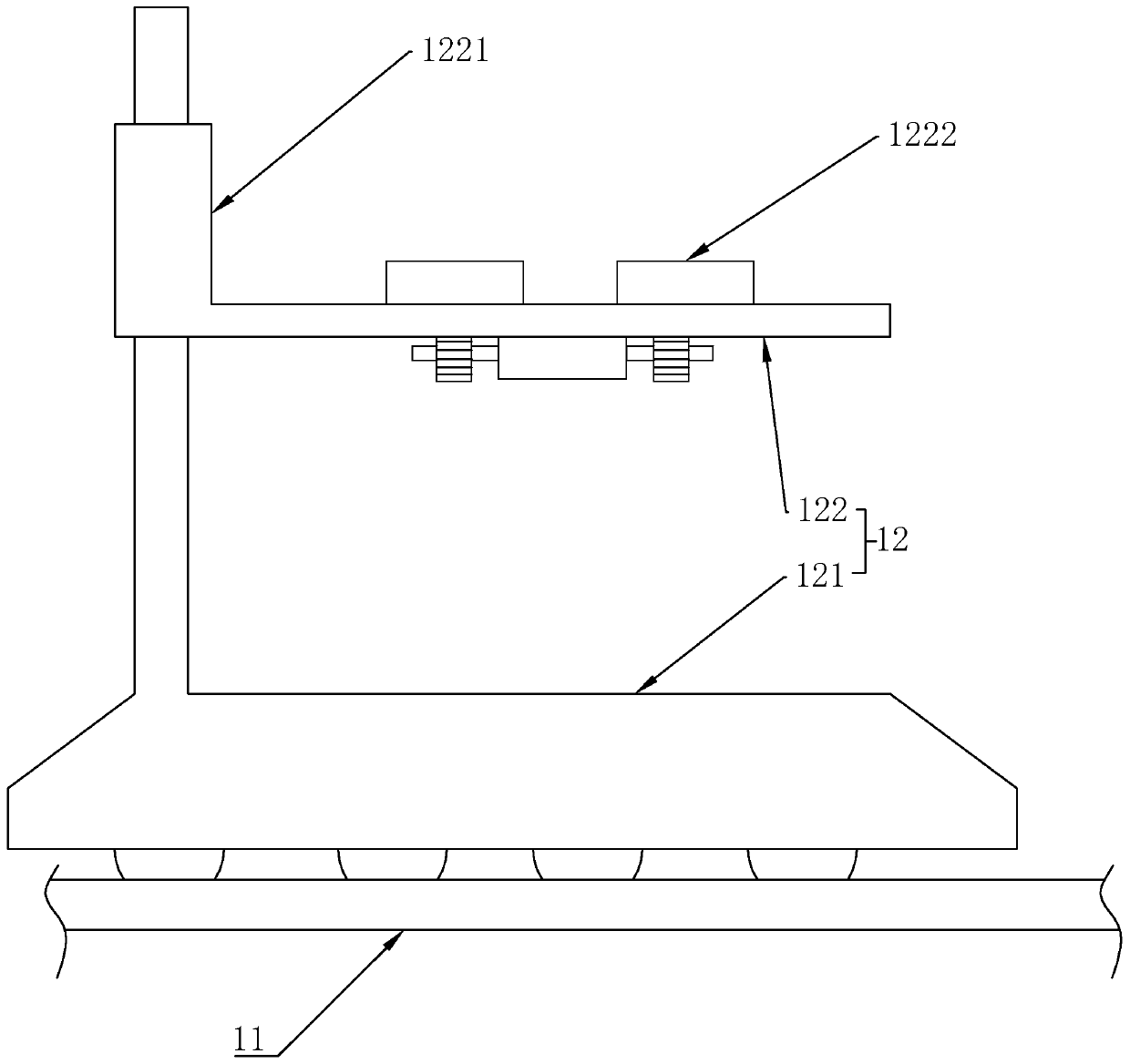

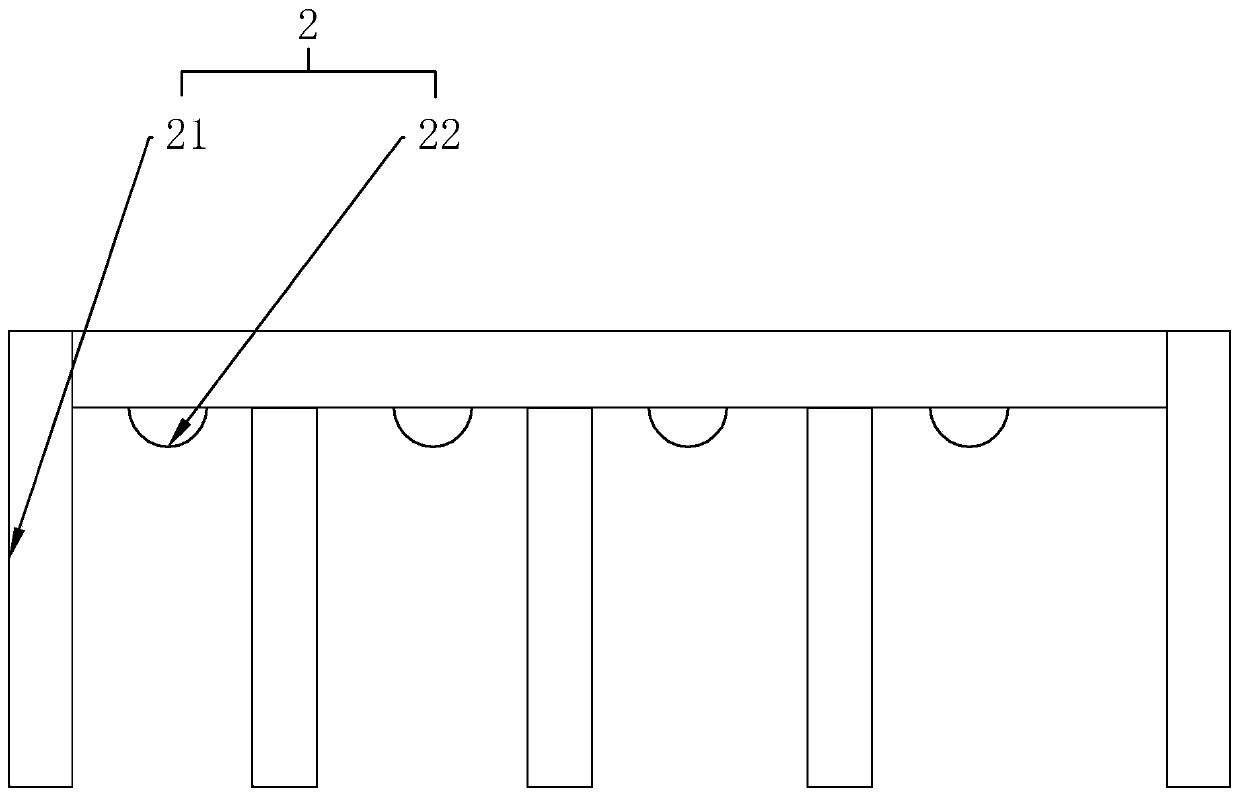

[0023] As an improved specific embodiment, the array loading mechanism 3 includes a loading frame 31 and a loading platform 32 arranged on the loading frame 31, and the loading frame 31 is provided with a loading platform 32 for driving the loading frame. The up and down loading lift assembly 6 and the loading translation assembly 5 set on the loading platform 32. When the cargo modules are arrayed on the conveyor belt 22 to form a cargo module array, the loading translation assembly 5 grabs the cargo module array to load After that, the loading translation assembly 5 drives the cargo module array to move into the cargo hopper of the transport vehicle 4, and the loading elevator assembly 6 drives the loading platform 32 to descend to place the cargo module array in the cargo hopper of the transport vehicle 4 and pass The setting of the loading frame 31 and the loading platform 32, the loading lift assembly 6 and the loading translation assembly 5 can effectively realize the effe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com