Oil film stiffness and damping testing method based on experimental table of slide bearings

A sliding bearing, oil film stiffness technology, used in mechanical bearing testing and other directions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

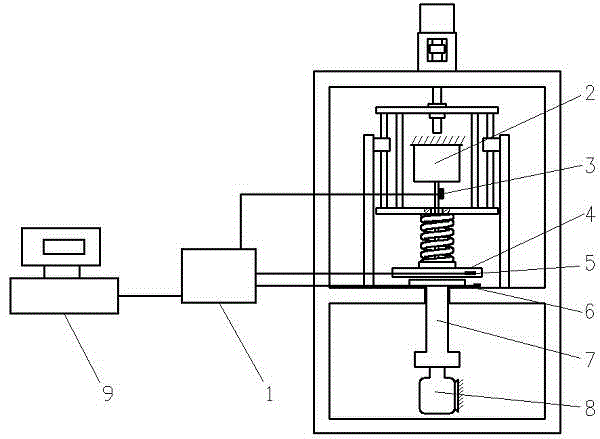

[0021] The present invention will be further described in detail below in conjunction with the accompanying drawings. The present embodiment uses a thrust bearing test bench for testing.

[0022] A test method for oil film stiffness and damping based on a sliding bearing test bench, comprising the following steps:

[0023] The first step, with reference to the accompanying drawings, put the sliding bearing 4 to be measured on the bearing seat of the sliding bearing test bench, the bearing seat is installed with a relative displacement sensor 5 and an absolute displacement sensor 6, and the relative displacement sensor 5 and the absolute displacement sensor 6 are used for measuring Relative displacement of sliding bearing 4 and absolute displacement Install the force sensor 3 on the exciter 2 to measure the exciting force, connect the relative displacement sensor 5, the absolute displacement sensor 6 and the force sensor 3 with the data acquisition card 1 respectively, and t...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap