Electromagnetic hoisting equipment of minibus total roof skin

A roof skin and hoisting equipment technology, applied in the direction of motor vehicles, transportation and packaging, etc., can solve the problems of four U-shaped parts occupying space, four U-shaped parts fully welded, affecting production safety, etc., to achieve lifting and The effect of stable and convenient placement, improved assembly process, and easy production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to describe the technical content of the present invention more clearly, further description will be given below in conjunction with specific embodiments.

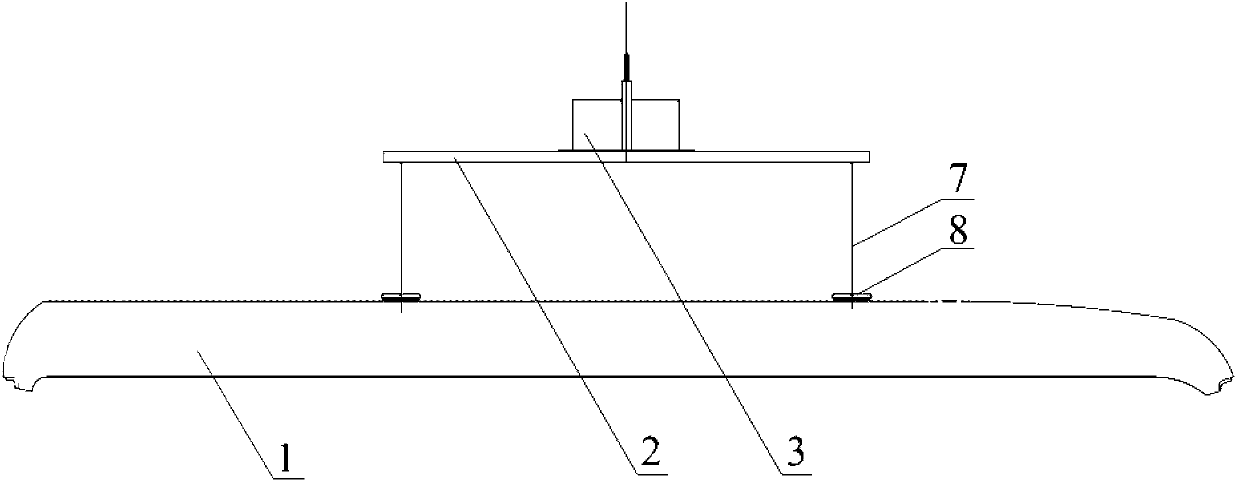

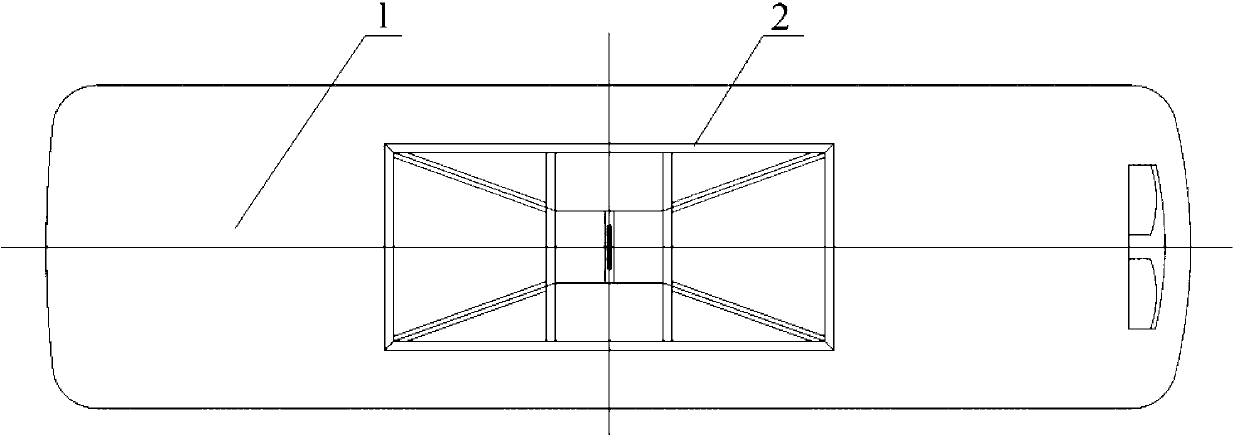

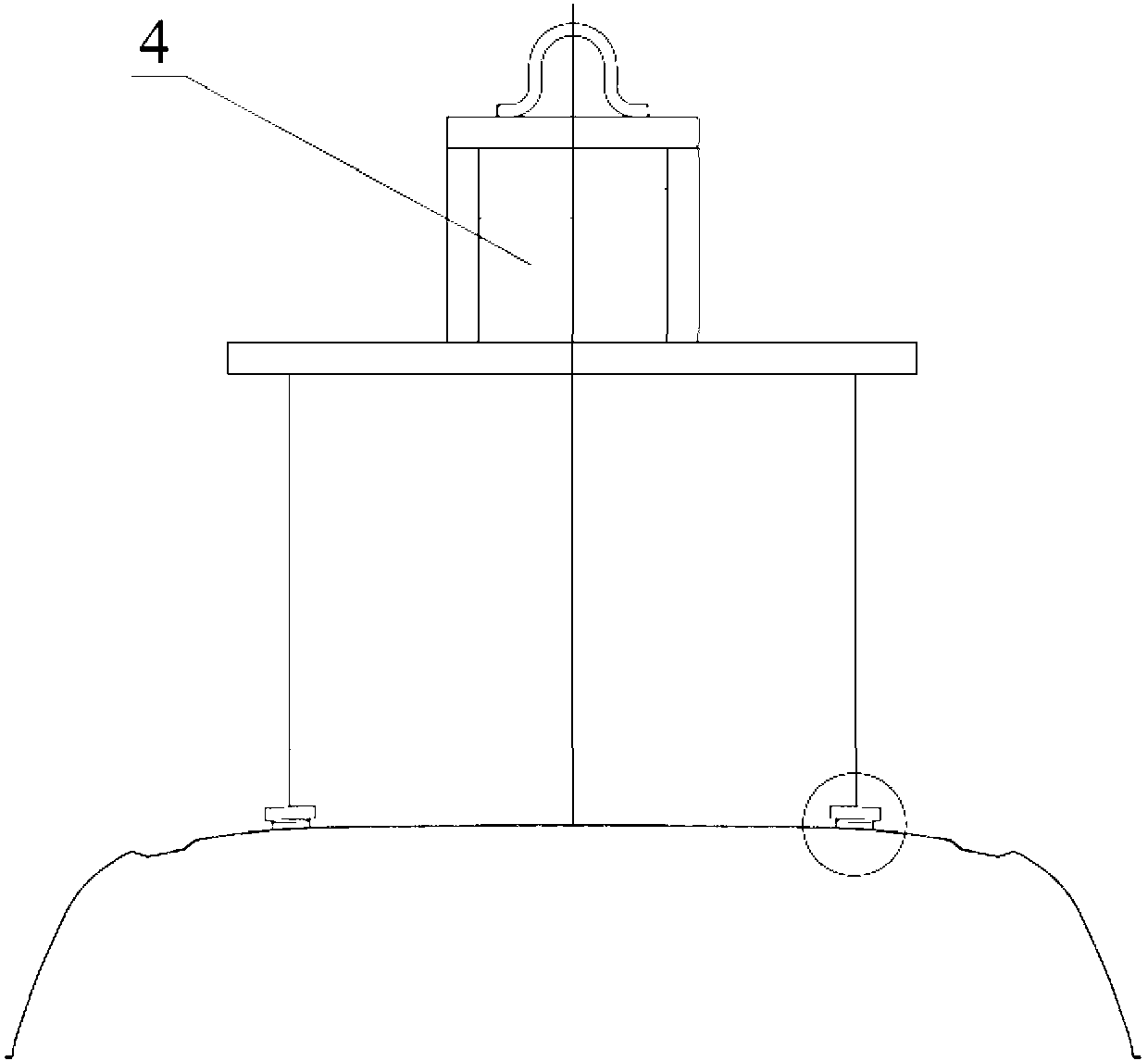

[0027] The present invention is designed according to meeting the needs of vehicle manufacturers with medium-sized passenger cars and other vehicles with large arch skins in the hoisting and assembling link of the roof skin, so that the hoisting is stable and the operation is convenient. If necessary, it can also be used for hoisting other equipment according to the needs of use. It only needs to modify the structural shape of the electromagnet assembly in the present invention according to the invented design method so that it can reach stable contact with the hoisted parts.

[0028] In order to solve the above-mentioned deficiencies in the prior art, the present invention invents a high-efficiency roof skin hoisting device used on the production line of medium-sized passenger cars by utilizing the principl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com