Patents

Literature

38results about How to "Guarantee the safety of hoisting" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

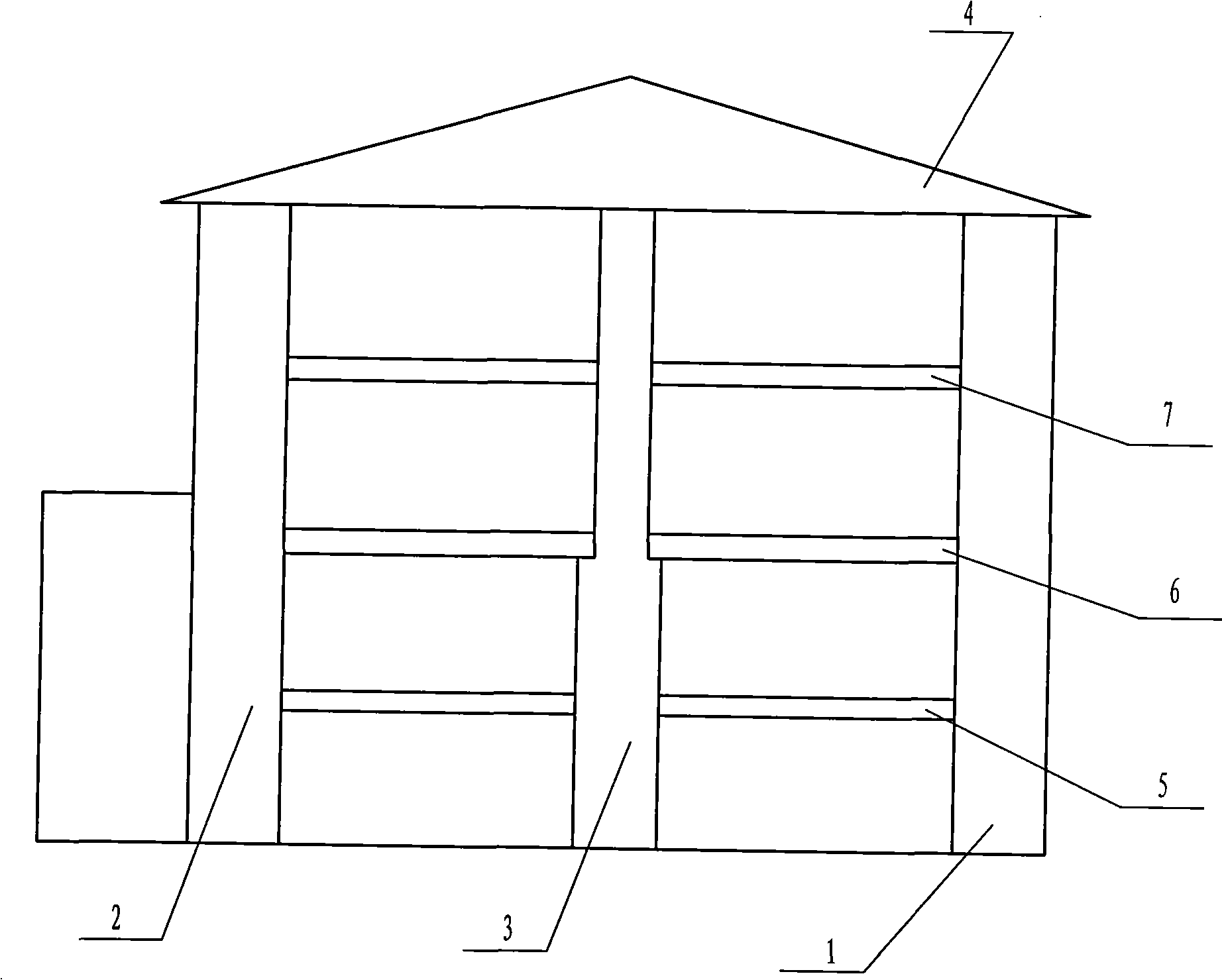

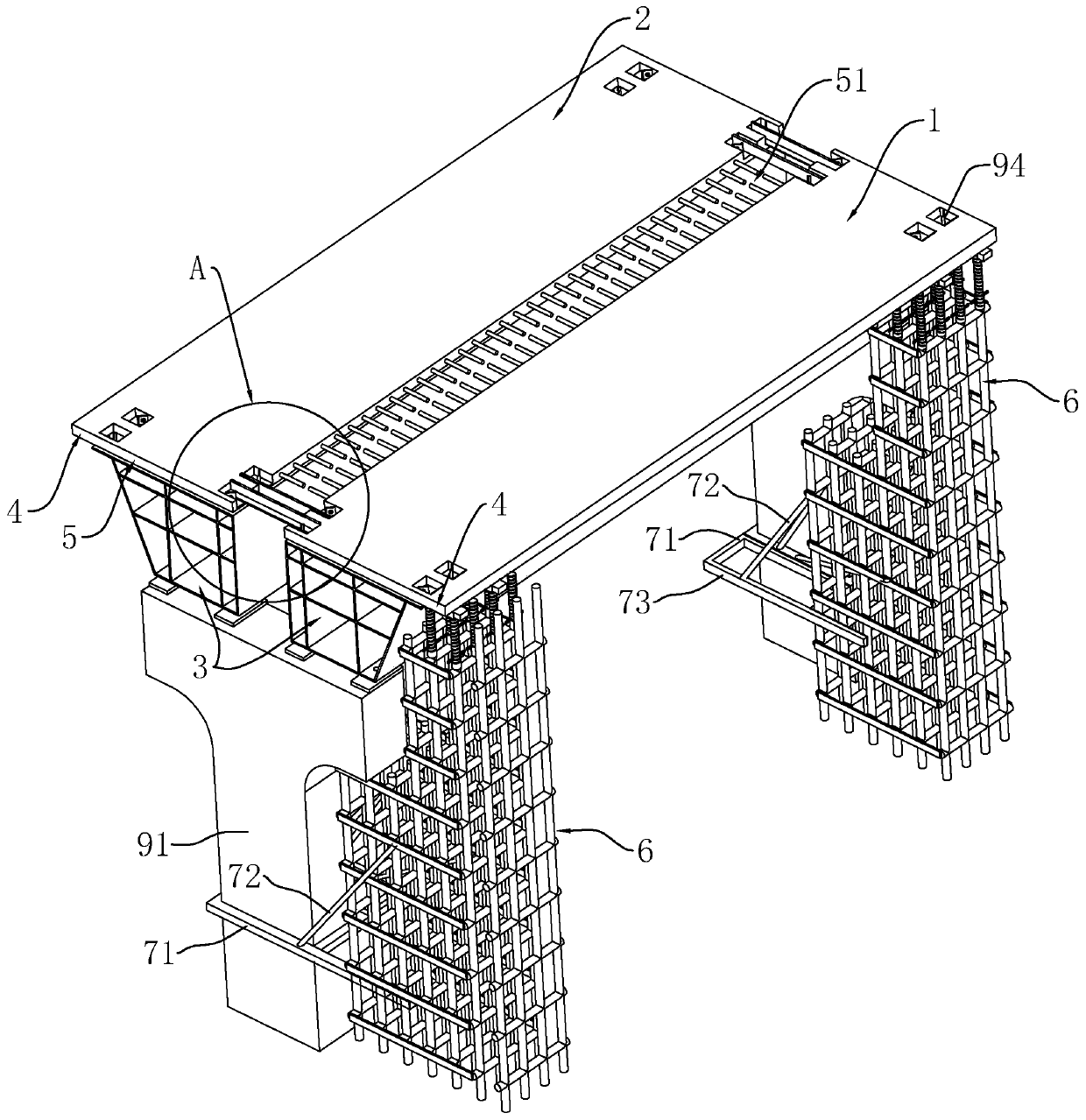

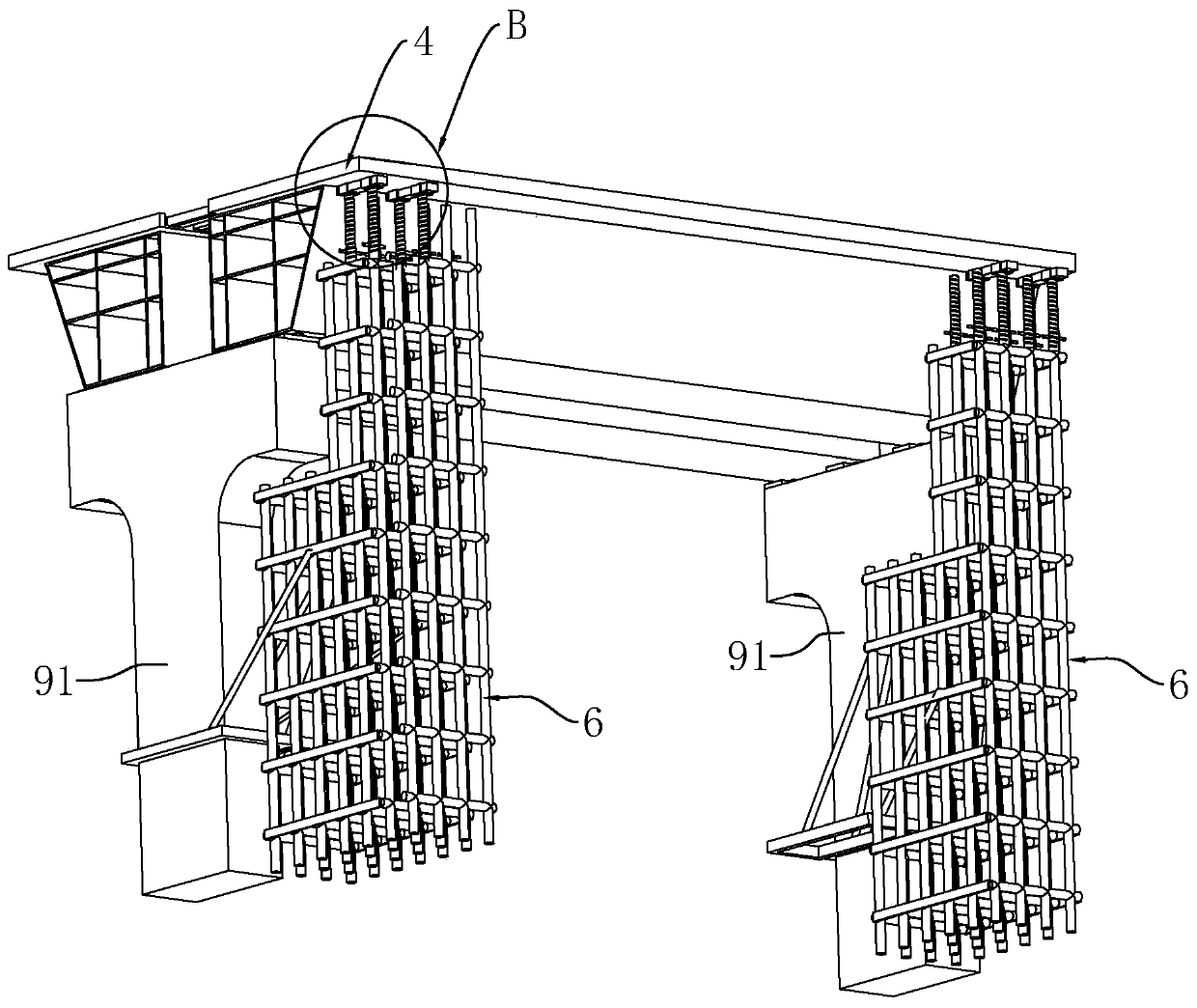

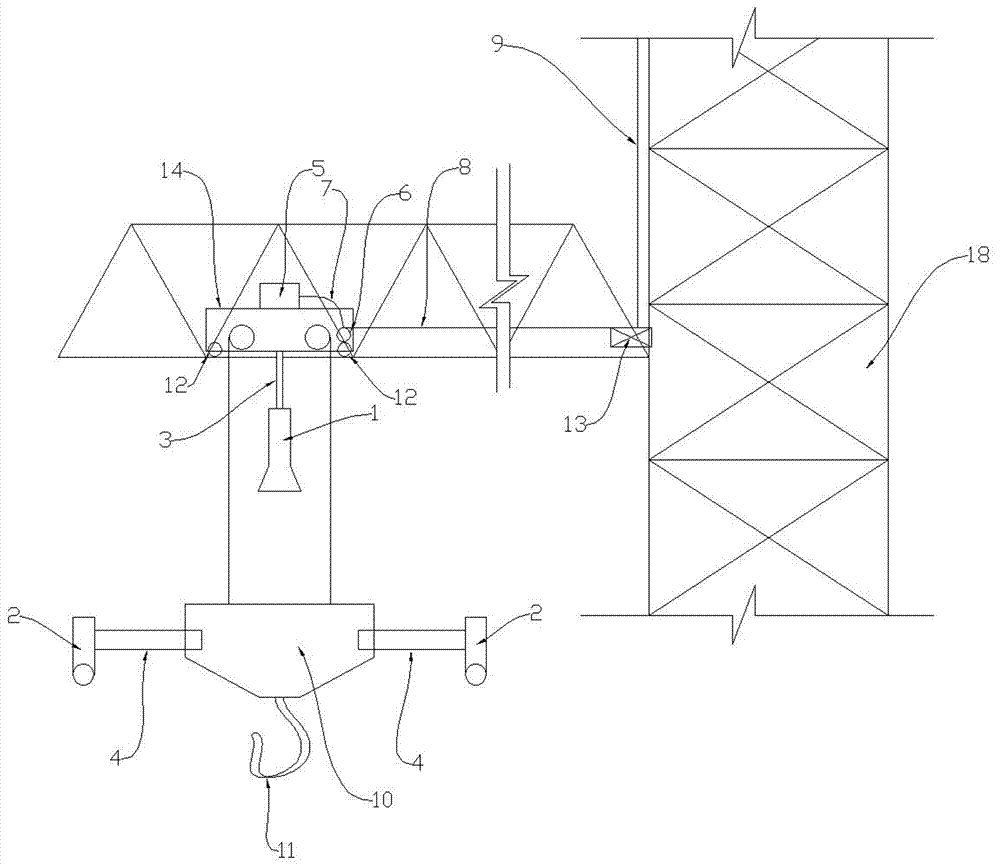

Reinforced concrete building top-down method construction process

InactiveCN101324088AGuaranteed structural constructionShorten the construction periodForms/shuttering/falseworksFoundation engineeringReinforced concreteSteel frame

The invention discloses a reinforced concrete building topdown method construction process, comprising the steps as follows: 1: the foundation, foundation and independent pile foundation construction is carried out; 2: a left supporting concrete column, a right supporting concrete column and a middle supporting concrete column of steel frame are established; 3: the areas between the left supporting concrete column and the middle supporting concrete column and areas between the right supporting concrete column and the middle supporting concrete column are used as hoisting passages of hoisting steel frame; each steel frame is hoisted onto the left supporting concrete column, the right supporting concrete column and the middle supporting concrete column; 4: all steel frames are hoisted on the left supporting concrete column, the right supporting concrete column and the middle supporting concrete column; after the connection and fixing operation, all steel frames are used as the roof of the reinforced concrete building; 5: in the roof, the indoor concrete frame structure is constructed. The method of the invention firstly constructs the side frame and the middle frame column structure, subsequently carries out the hoisting of the steel frame, and constructs the reinforced concrete structure in the clean area after the roof surface has no water, thus saving the construction period, reducing the cost, ensuring the safety hoisting, overcoming the effect of weather and ensuring the construction period and the construction quality.

Owner:CHINA METALLURGICAL CONSTR ENG GRP

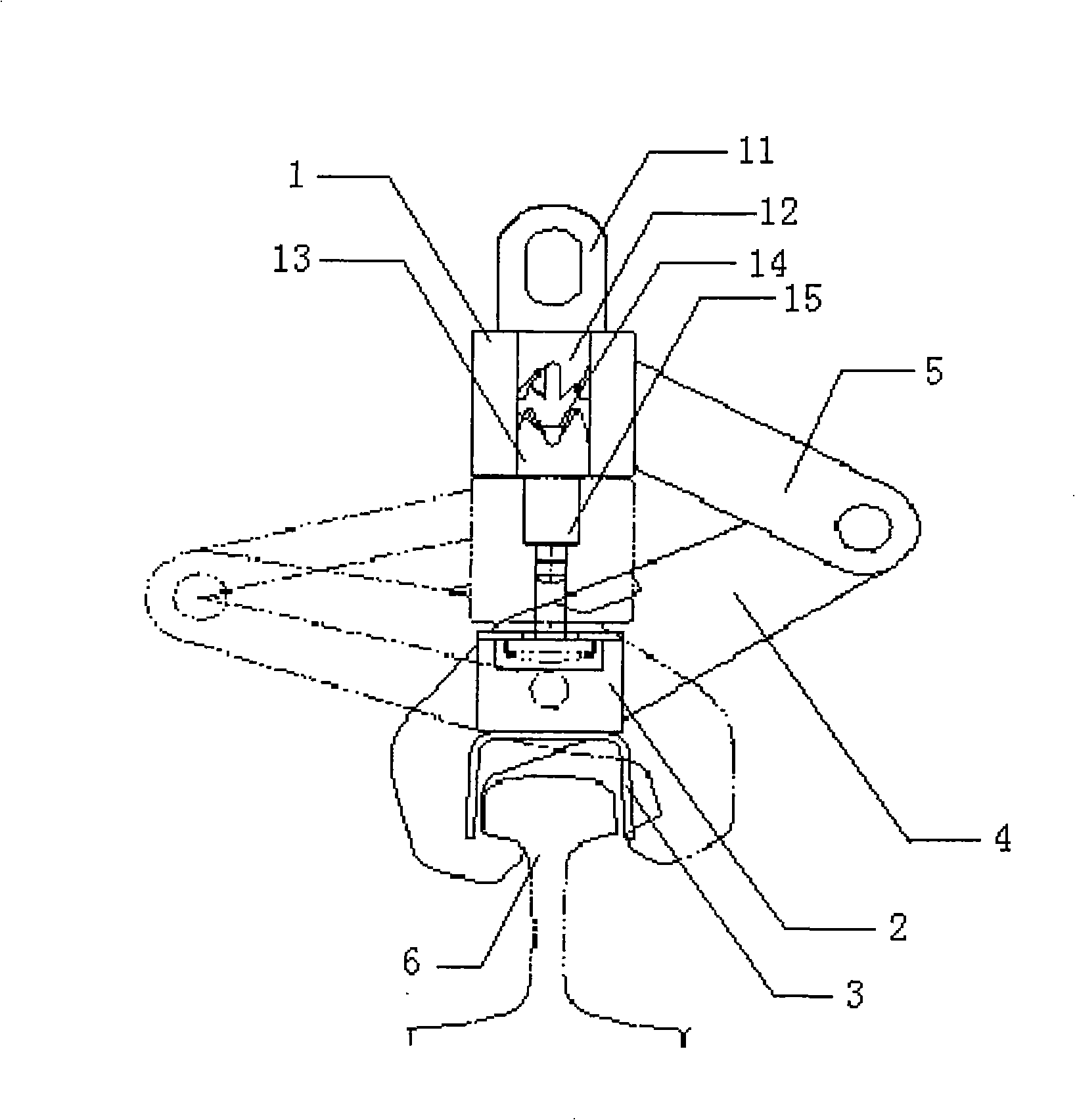

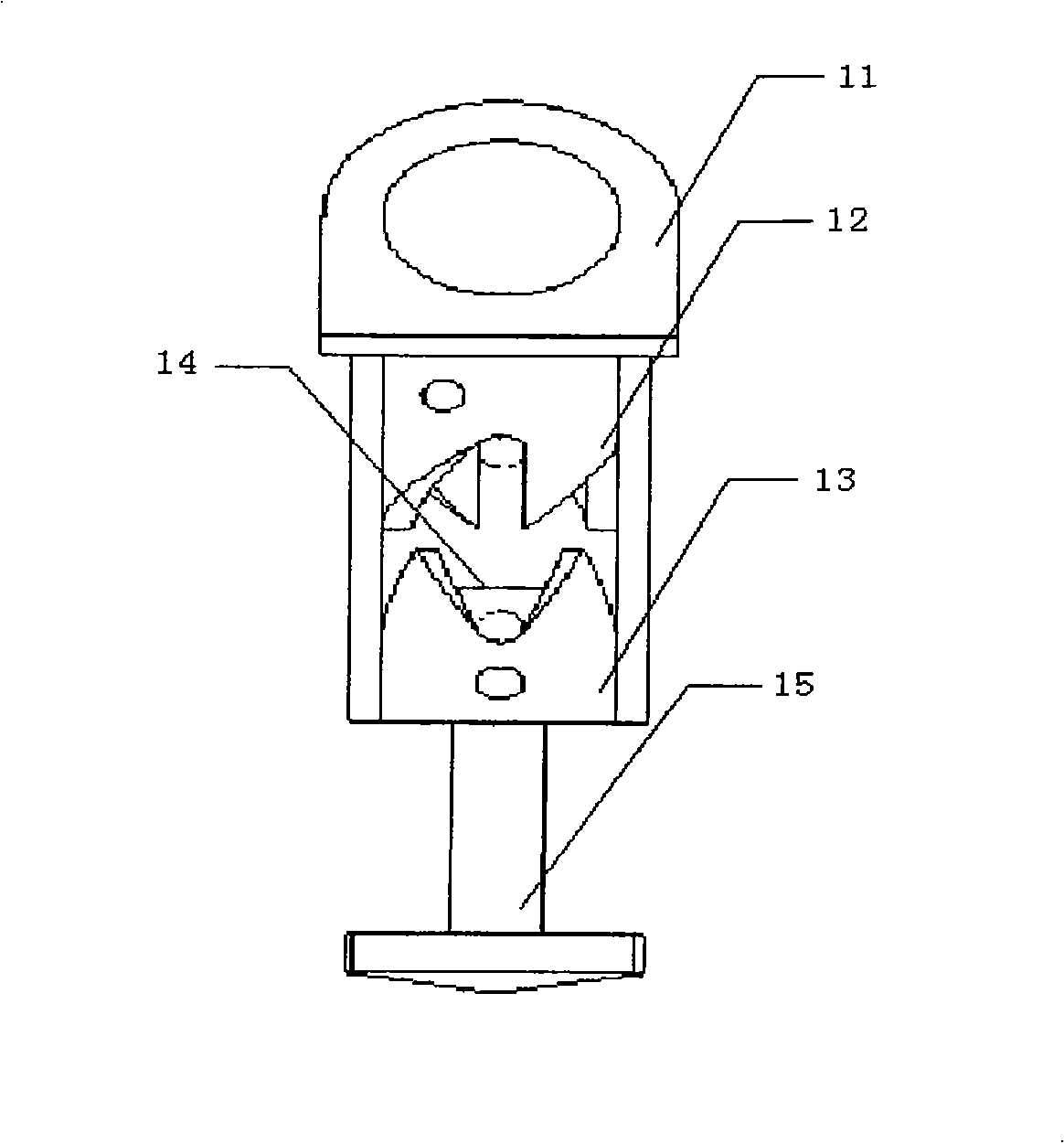

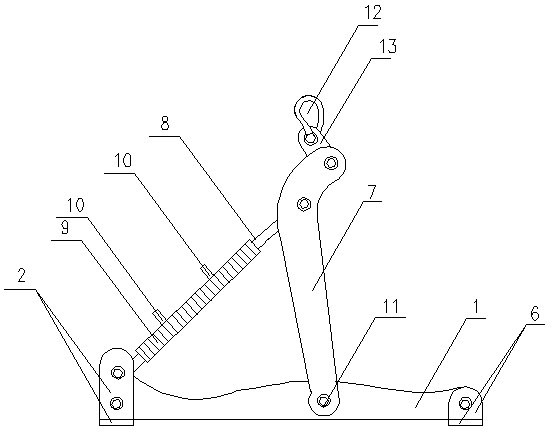

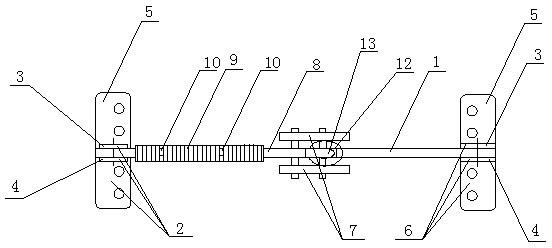

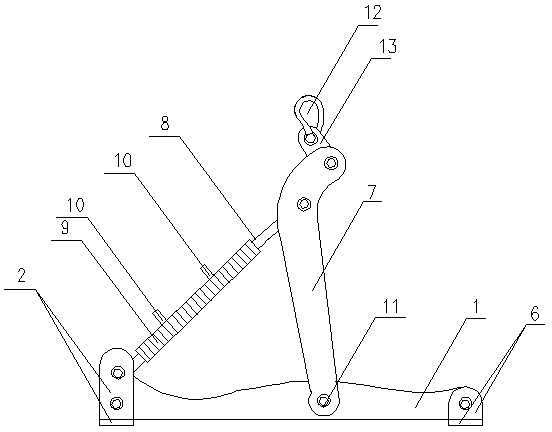

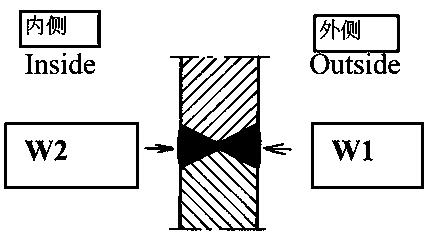

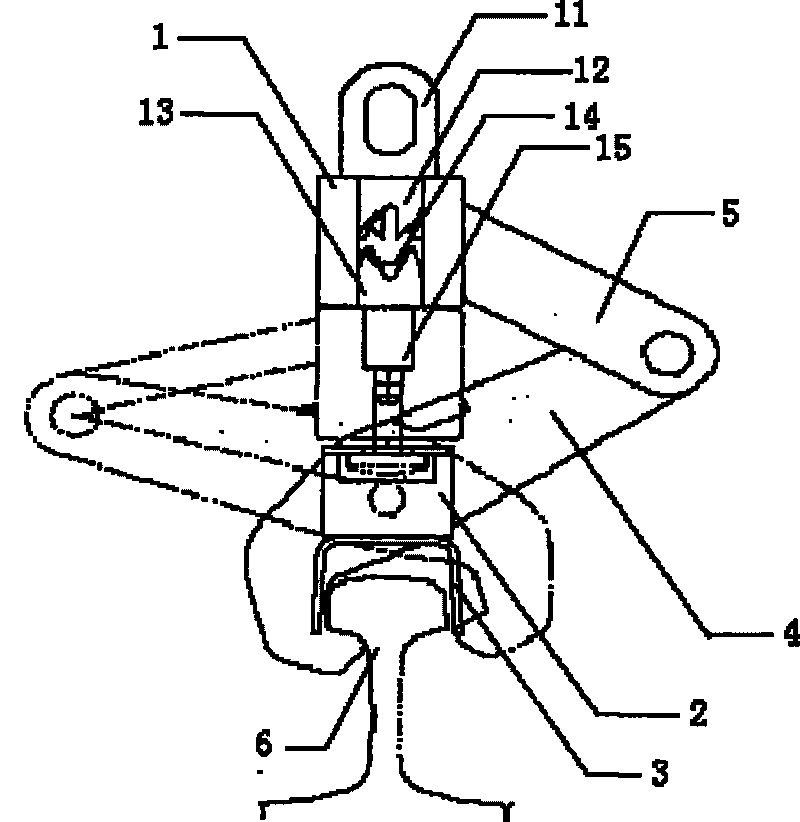

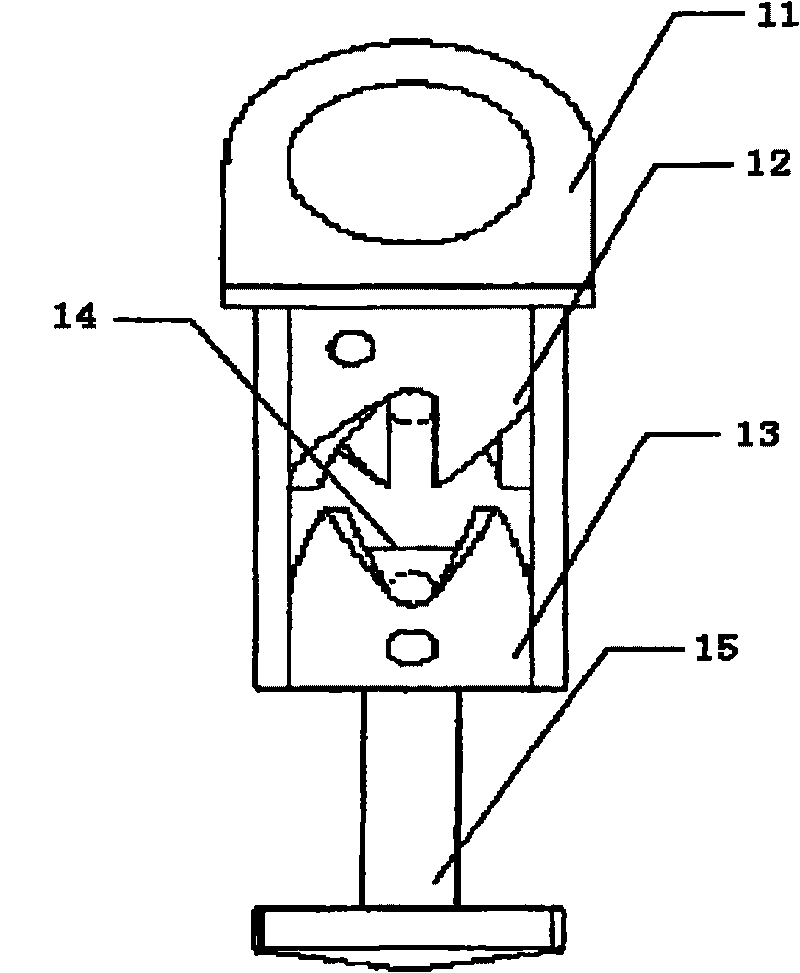

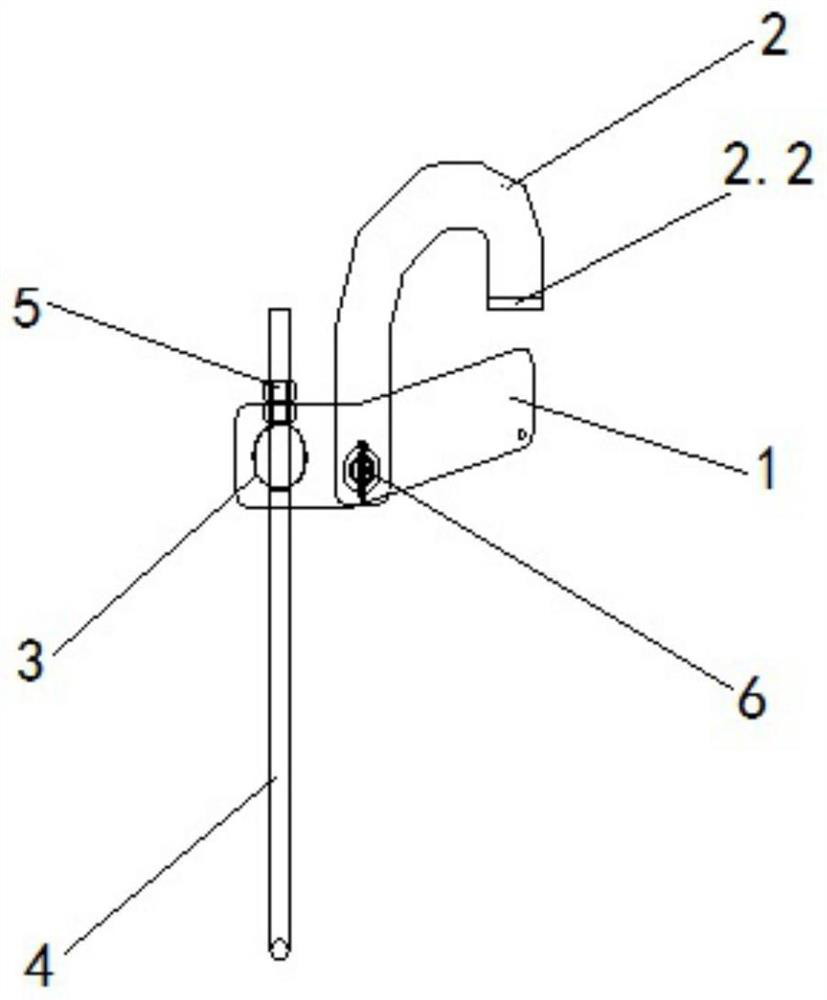

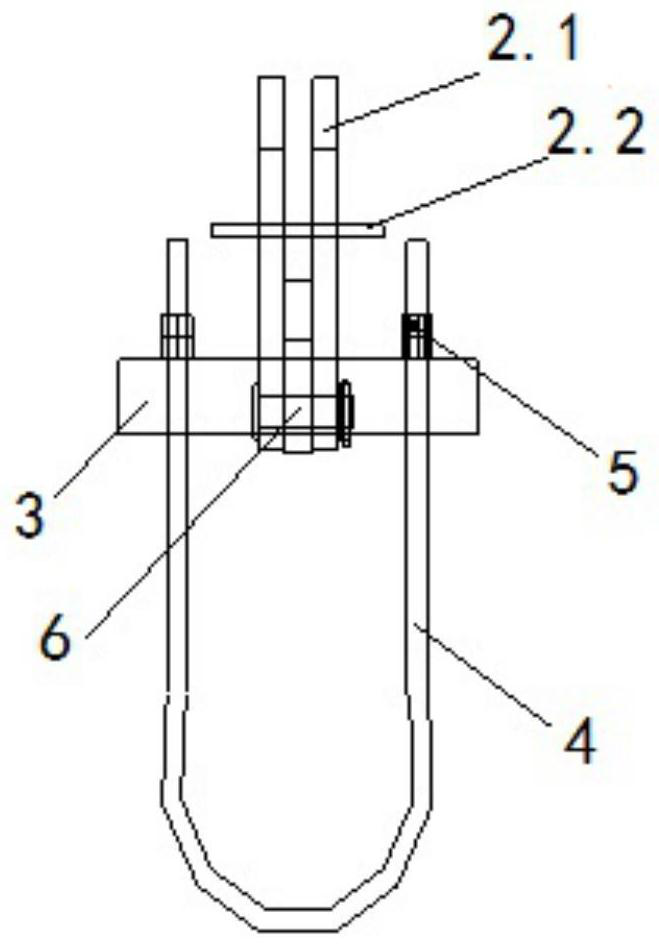

Mechanical type automatic rail gripping apparatus

InactiveCN101327889AImprove securitySimple, lightweight and reliableLoad-engaging elementsSelf lockingWorking environment

Owner:武汉凯盟机电工程有限公司

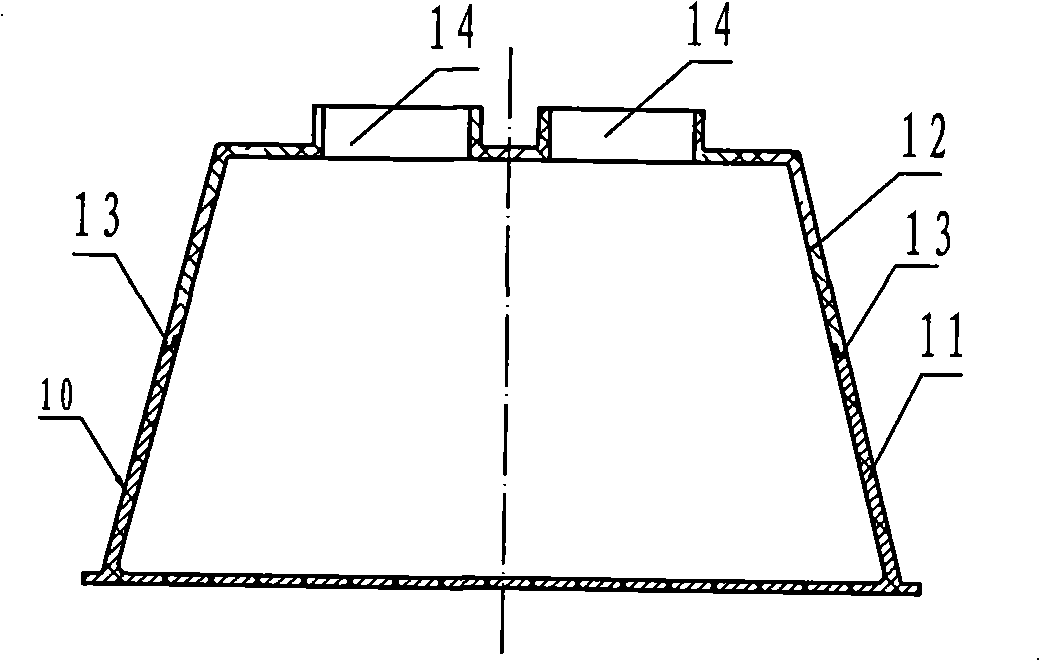

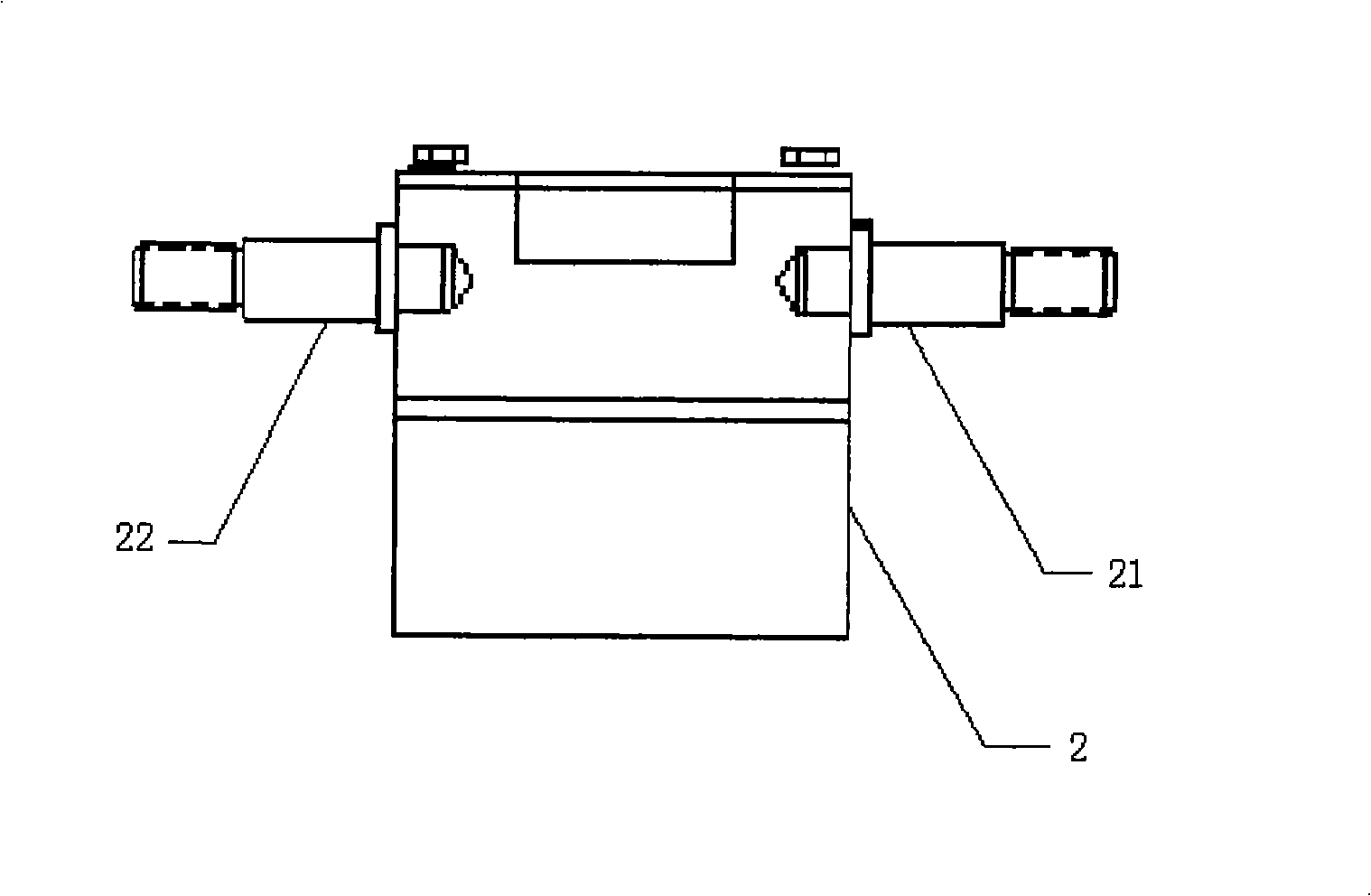

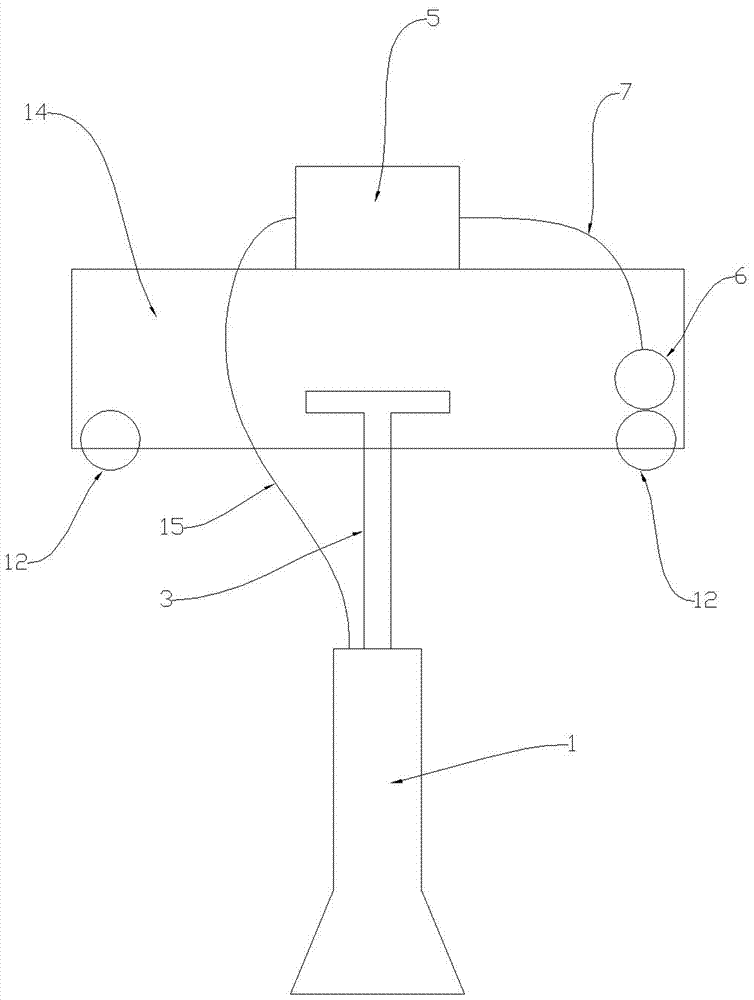

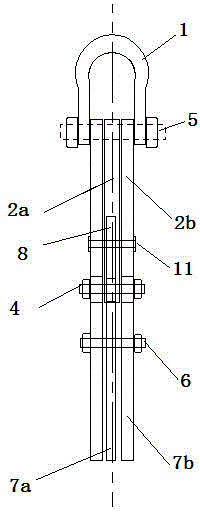

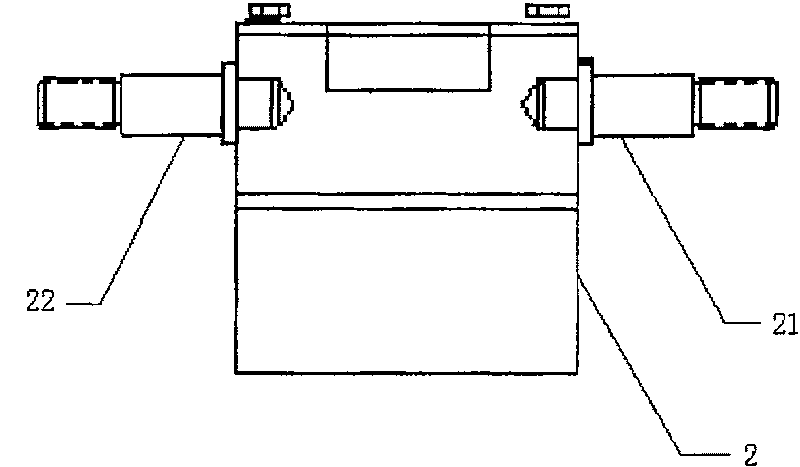

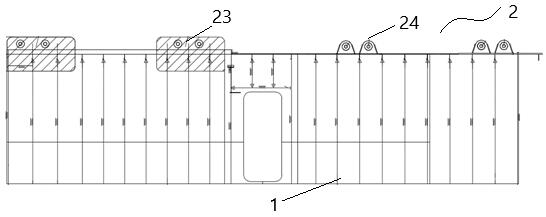

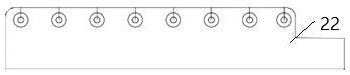

Hydraulic adjustable hub sling for wind-driven generator

The invention relates to a hydraulic adjustable hub sling for a wind-driven generator and belongs to a mounting sling for the wind-driven generator. The hydraulic adjustable hub sling is characterized by mainly comprising a main suspension arm, adjusting arms, a left connecting seat board, a right connecting seat board, a hoisting board and a shackle, wherein the main suspension arm is a long strip-shaped vertical panel which is laterally arranged; connecting holes are respectively formed in the left end part, the right end part and the middle of the main suspension arm; the left connecting seat board and the right connecting seat board are fixedly arranged in the connecting holes in the left end part and the right end part of the main suspension arm; the left connecting seat board and the right connecting seat board are mainly formed by welding a base plate and front vertical plates as well as rear vertical plates; holes are formed in the upper parts of the front and rear vertical plates of the left connecting seat board; hydraulic oil cylinders are hinged in the holes of the front and rear vertical plates of the left connecting seat board by pin rolls; two bolt holes are respectively formed in the base plate; front and rear adjusting arms are hinged in the connecting hole in the middle of the main suspension arm by using pin rolls; holes are formed in the upper sections of the front and rear adjusting arms; a piston rod is hinged in the holes of the front and rear adjusting arms by using pin rolls; holes are formed in the upper end sections of the front and rear adjusting arms; the hoisting plate is hinged in the holes in the upper end sections of the front and back adjusting arms by using pin rolls; the shackle is arranged on the hoisting plate; and the mounting angle of a hub is adjusted to be accurately aligned with a cabin.

Owner:CHINA MCC17 GRP

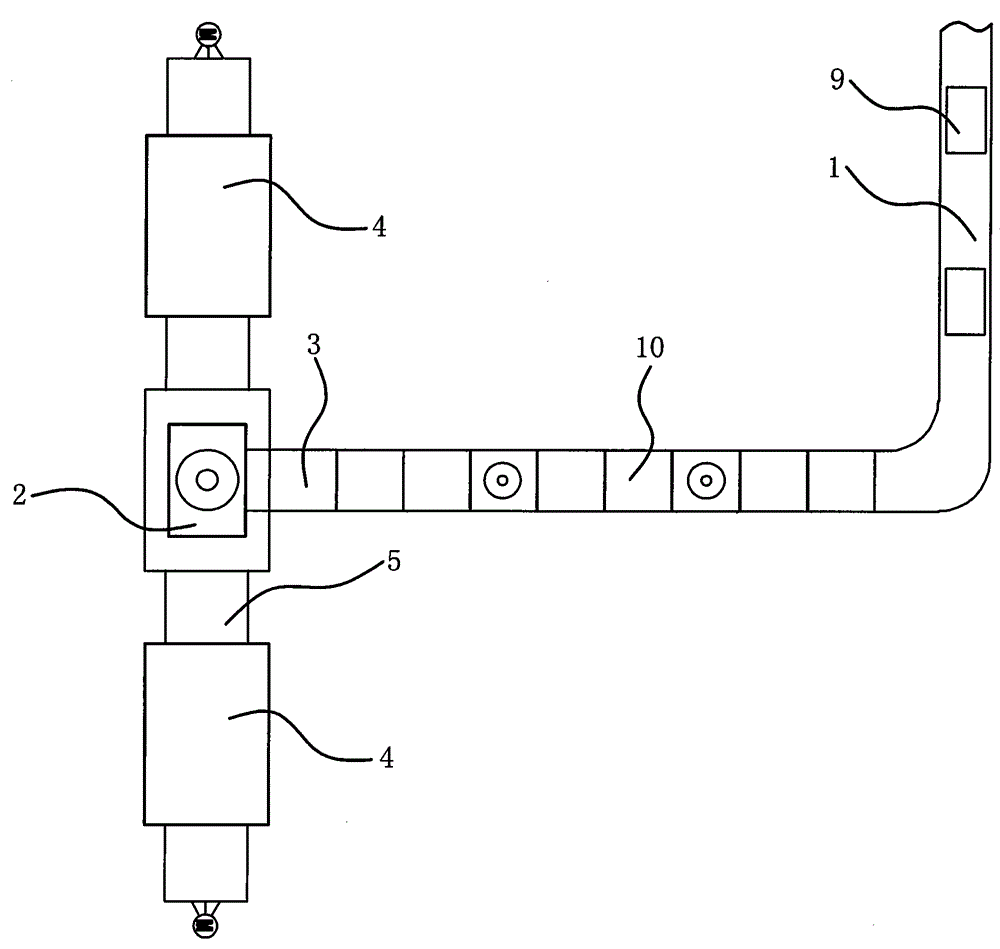

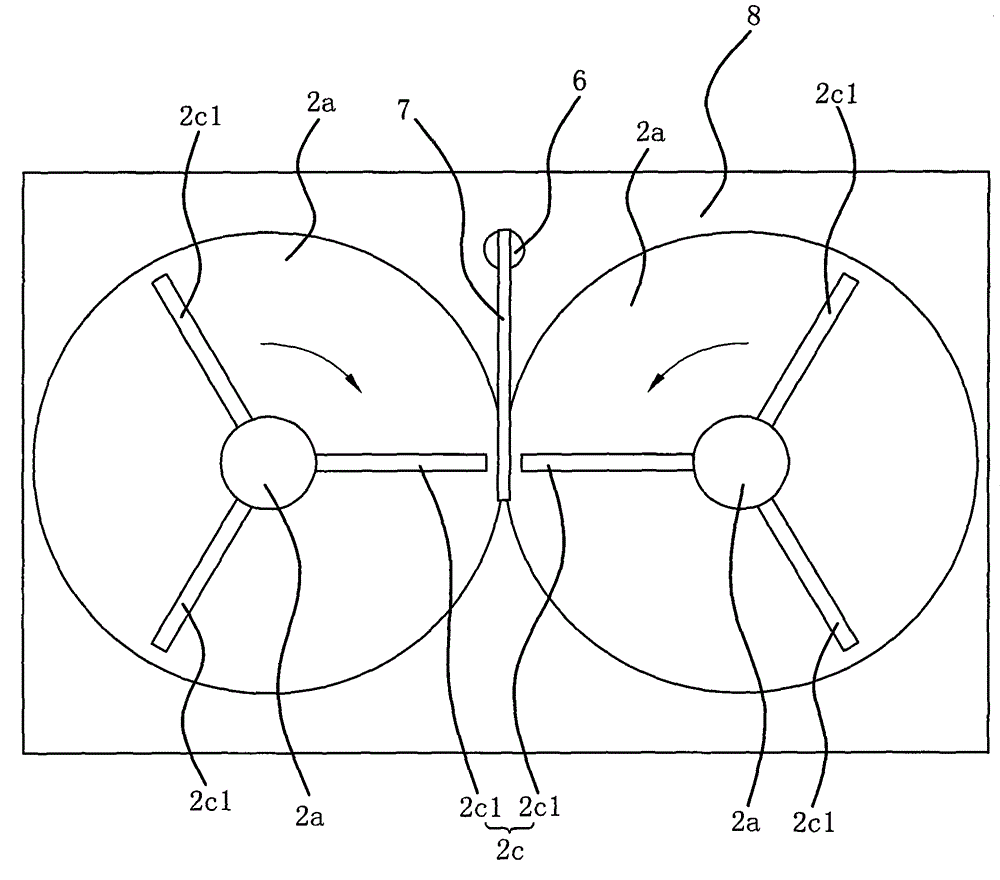

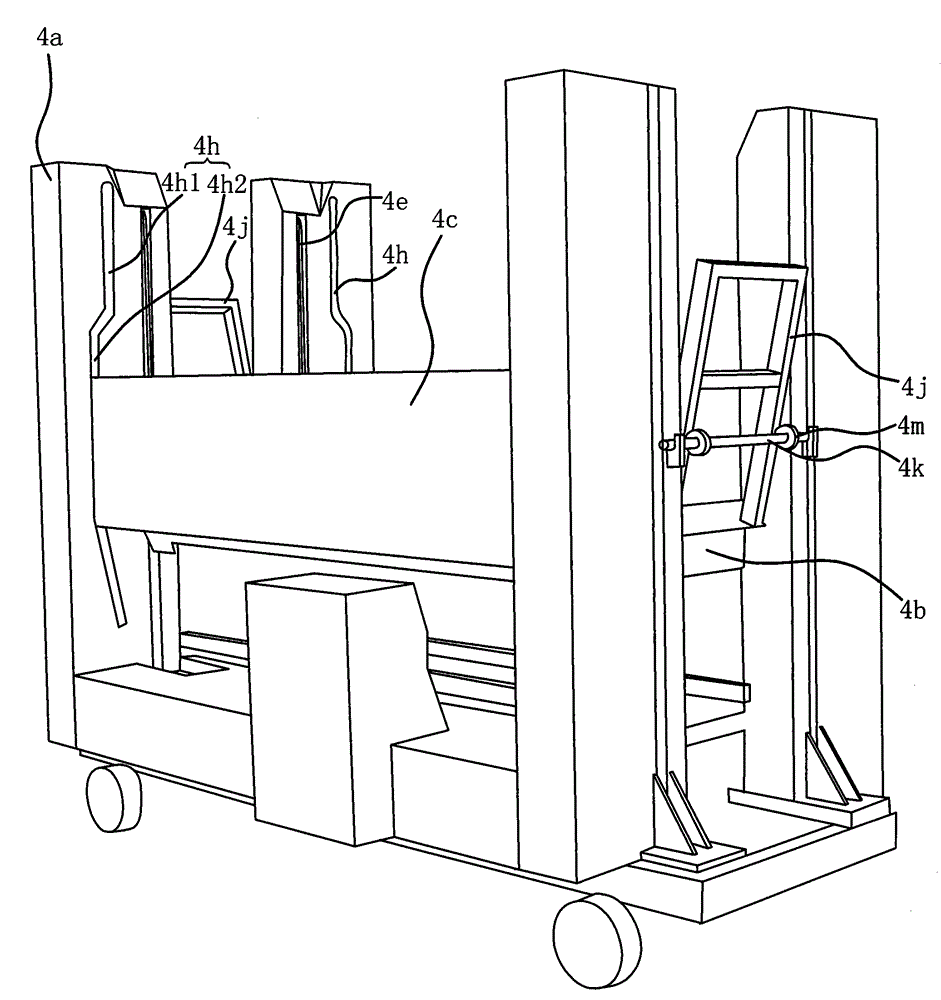

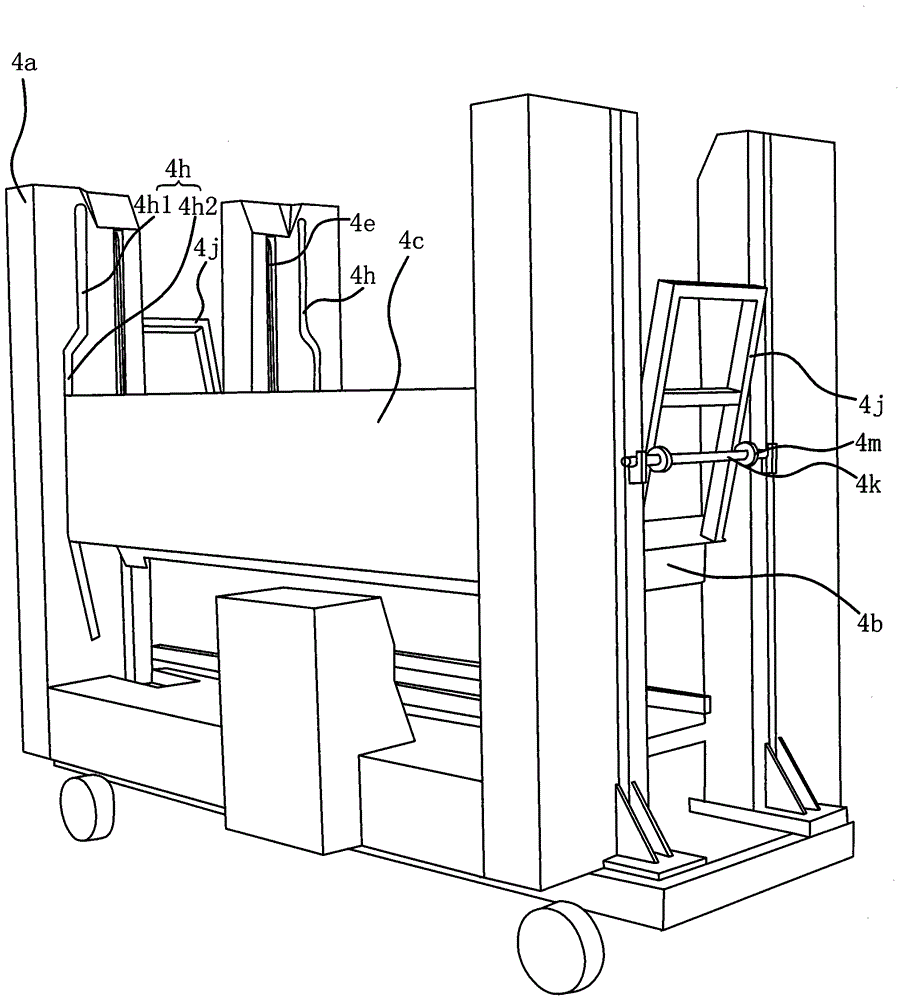

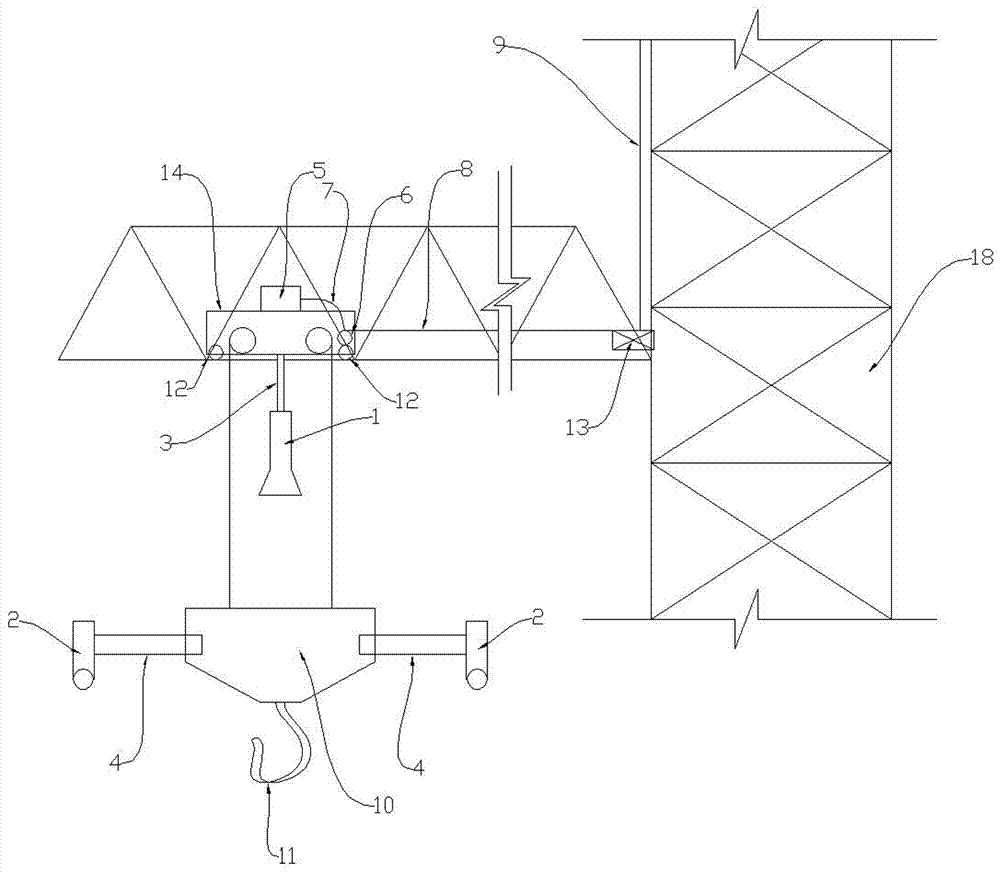

Automatic bag folding and integrated packaging system

InactiveCN104787584AReduce mechanical failureLower the altitudeStacking articlesEngineeringPackaging machine

The invention provides an automatic bag folding and integrated packaging system, and belongs to the technical field of works. The automatic bag folding and integrated packaging system solves the problems that an existing bag folding and integrated packaging machine is low in working efficiency, and many workers are needed. The automatic bag folding and integrated packaging system comprises a rack and a bag folding trolley. The rack is provided with a horizontal roller conveying line, a falling control device with a supporting plate and used for controlling falling of bags and a high-speed conveying line connected with the roller conveying line in series and capable of conveying the bags to fall on the supporting plate. The bag folding trolley is located below the falling control device. According to the automatic bag folding and integrated packaging system, the roller conveying line can adjust the postures and intervals of the bags automatically, and workers in the corresponding processes are saved; the high-speed conveying line guarantees that the bags totally fall on the supporting plate, and the postures of the bags falling on the supporting plate are the same, and thus the corresponding adjusting personnel is saved; at the bag folding trolley, only one lifting worker is needed to arrange a hook ring for lifting the bags in a lifting hook of a lifting device in a sleeving mode, and the automatic bag folding and integrated packaging system has the advantage that the workers required by operation are less.

Owner:林文彬

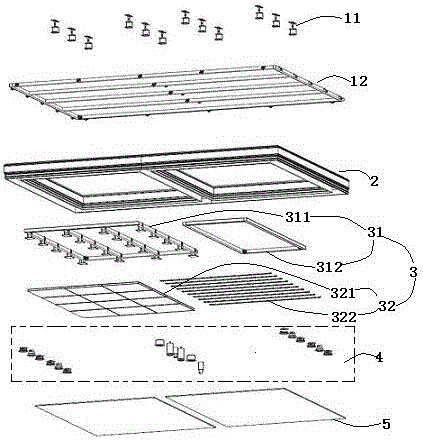

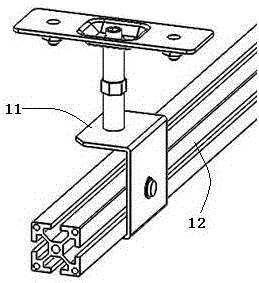

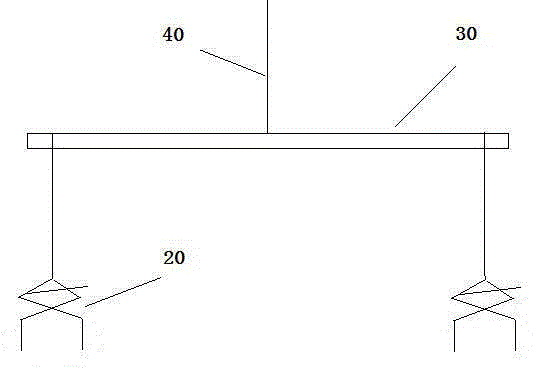

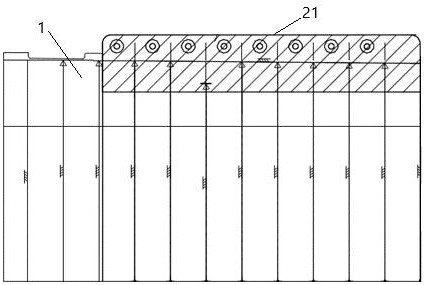

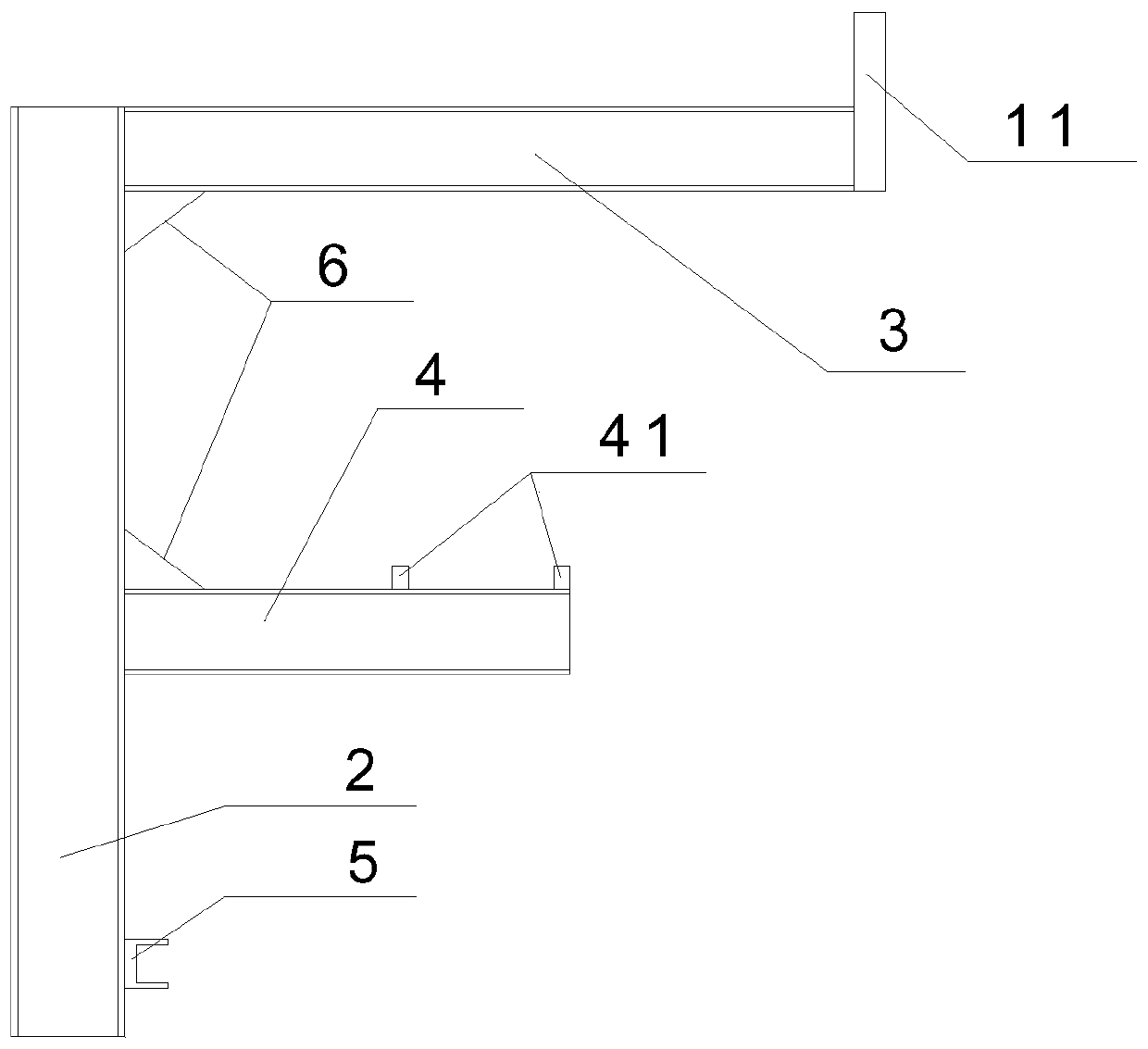

Suspended ceiling system

ActiveCN106088442AHigh strengthGuaranteed flatnessCeilingsSemiconductor devices for light sourcesAgricultural engineeringAtmosphere

The invention discloses a suspended ceiling system which comprises an installation support assembly, an integrated groove assembly, an LED light source assembly, an expansion assembly and a curtain. The support assembly comprises a pulling top installation support, an aluminum square tube transition support and support corner connectors. The integrated groove assembly is connected and fixed to the aluminum square tube transition support through the support corner connectors. The integrated groove assembly comprises an integrated groove main frame, an integrated groove buckle and an integrated groove lower baffle. The integrated groove buckle is installed on the integrated groove main frame through buckles on the two sides, and the integrated groove lower baffle is installed on the integrated groove buckle through baffle buckles. The modular suspended ceiling system is simple and firm in structure, the structural strength of a suspended ceiling is ensured, different illumination effects and atmospheres can be created, and accordingly application requirements of the suspended ceiling system on different occasions are met.

Owner:惠州雷士光电科技有限公司

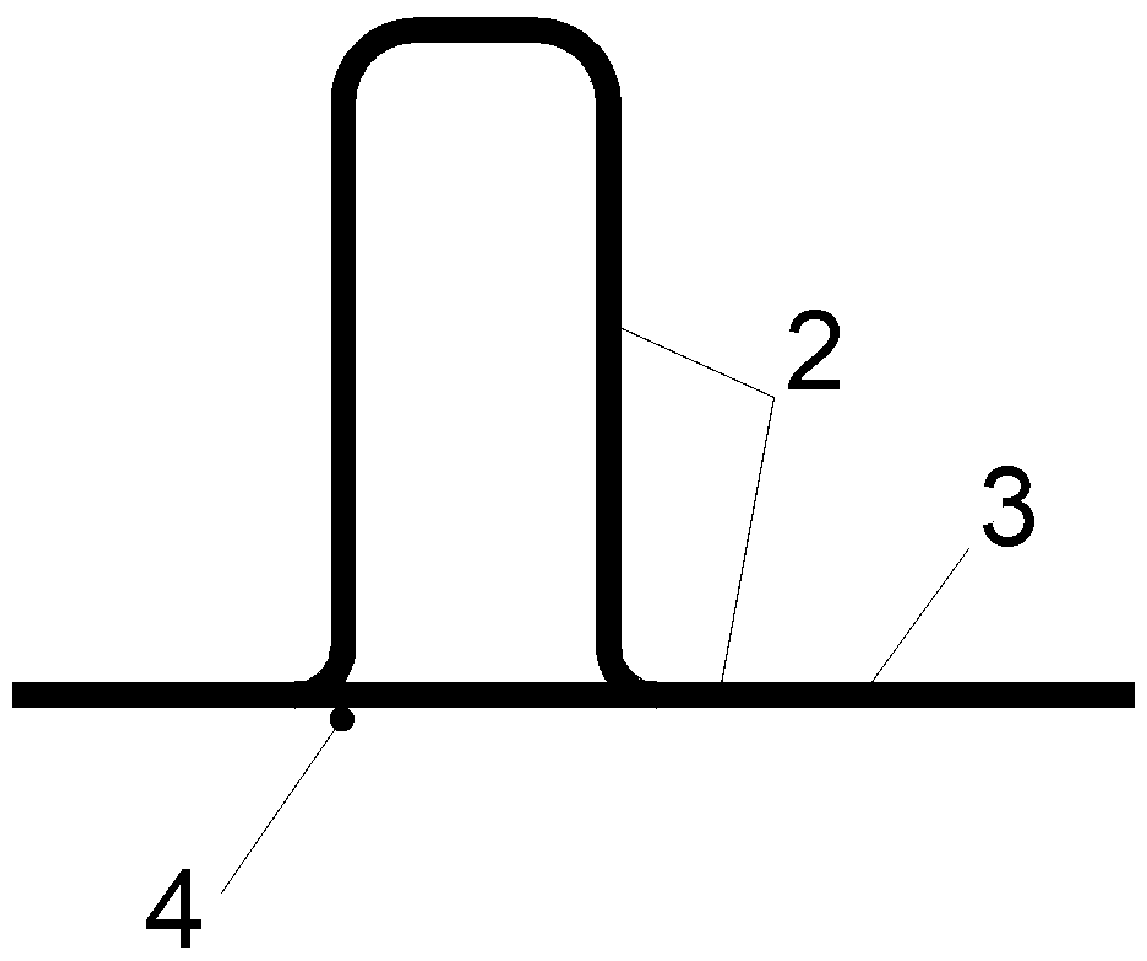

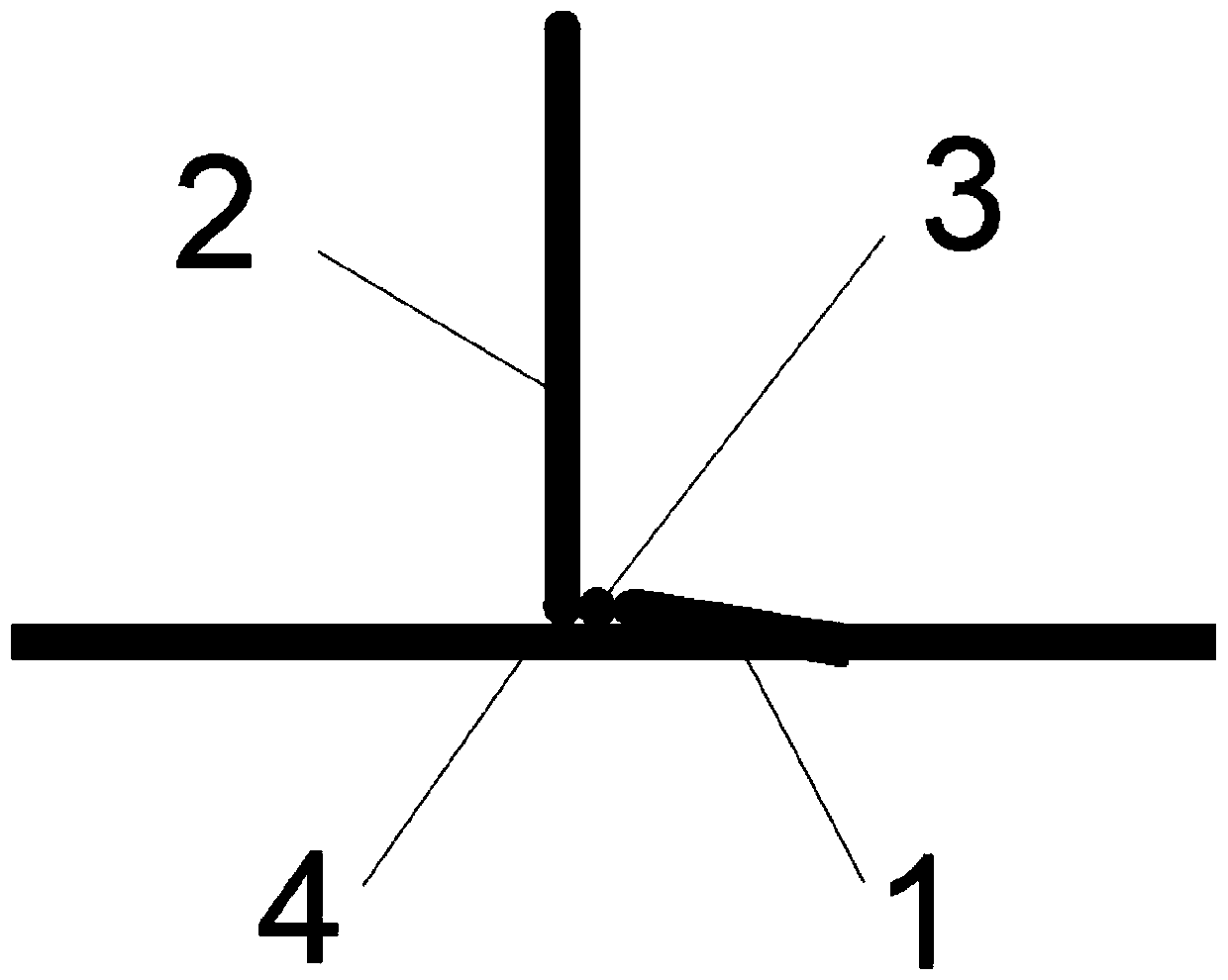

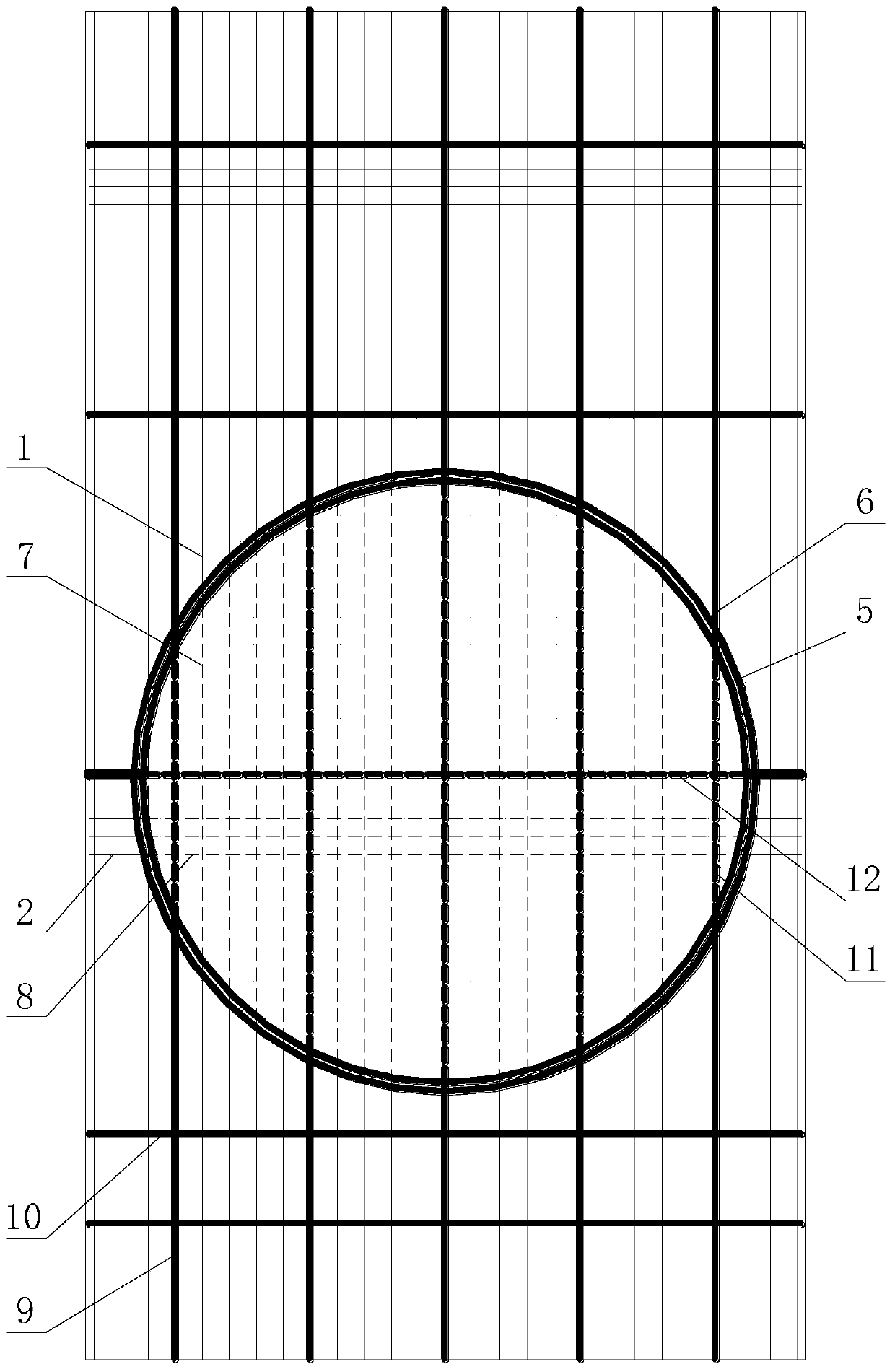

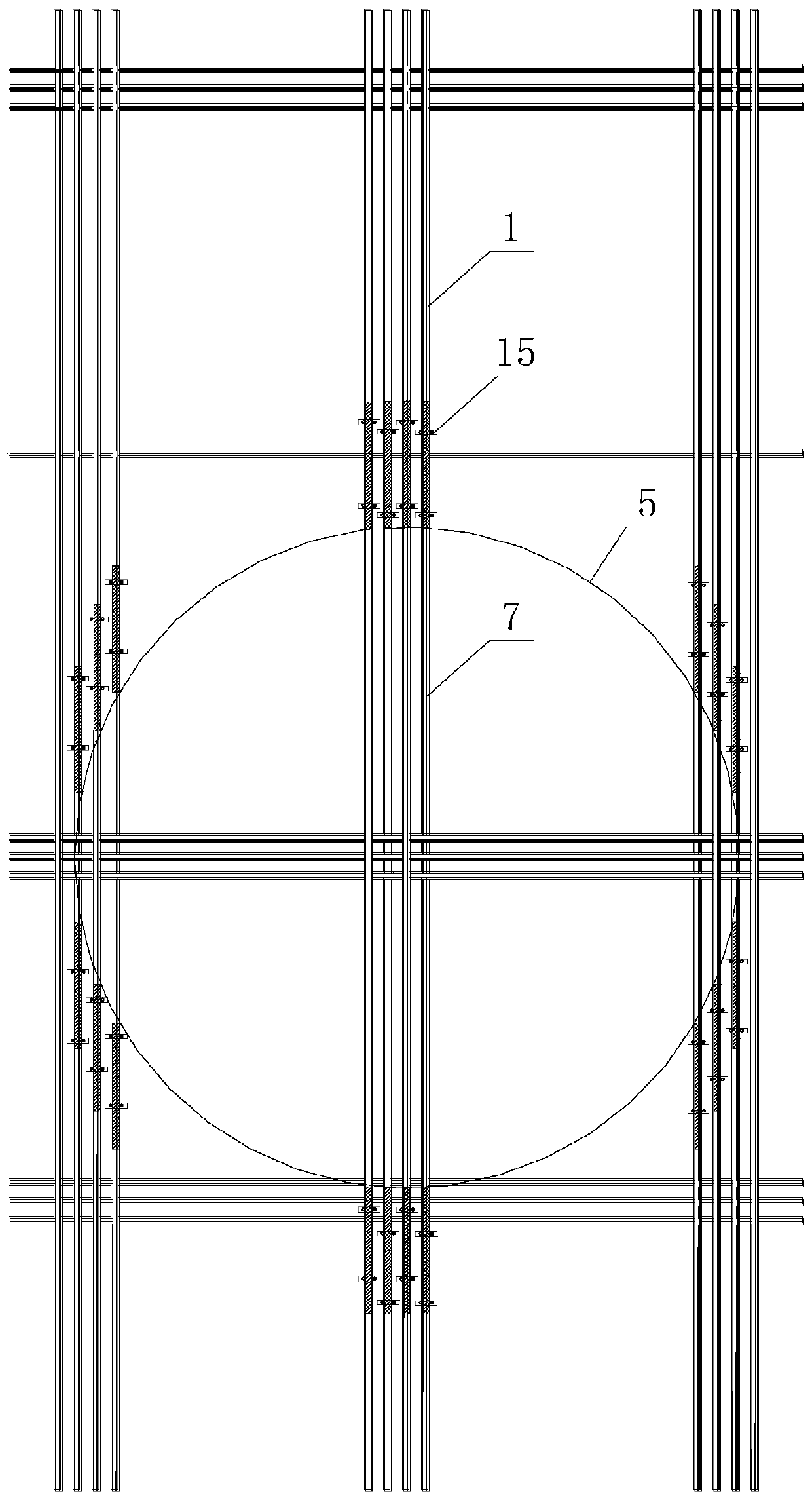

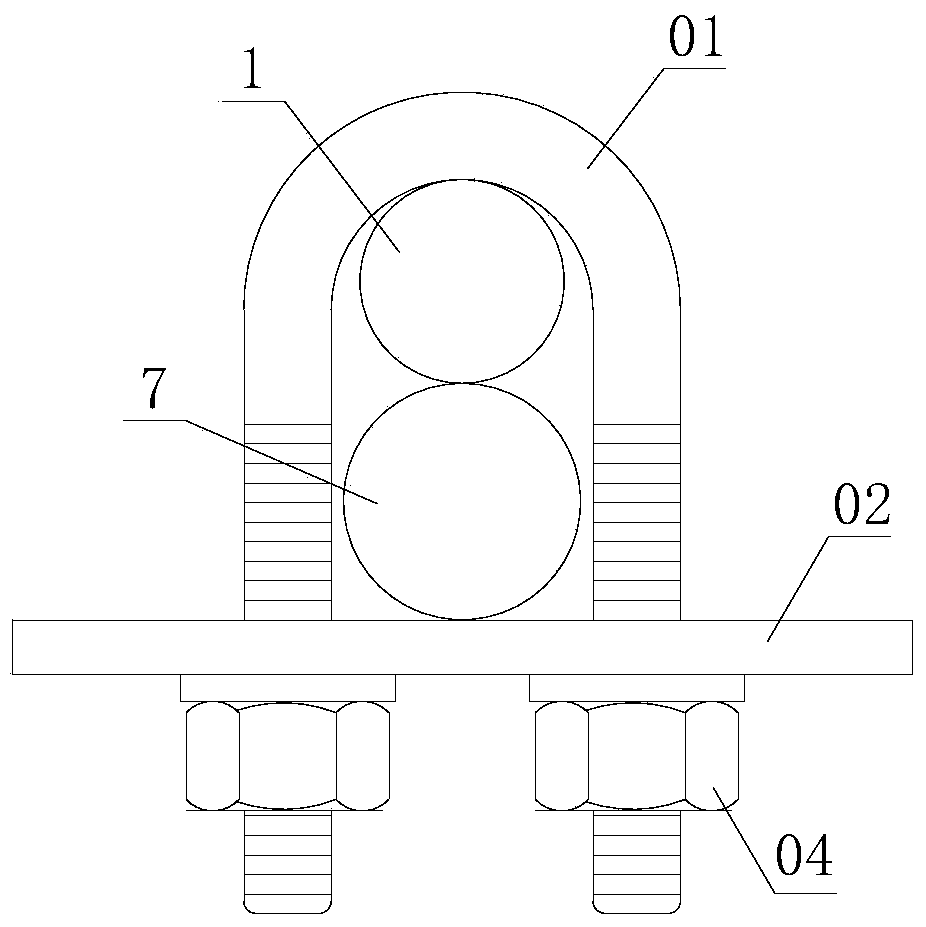

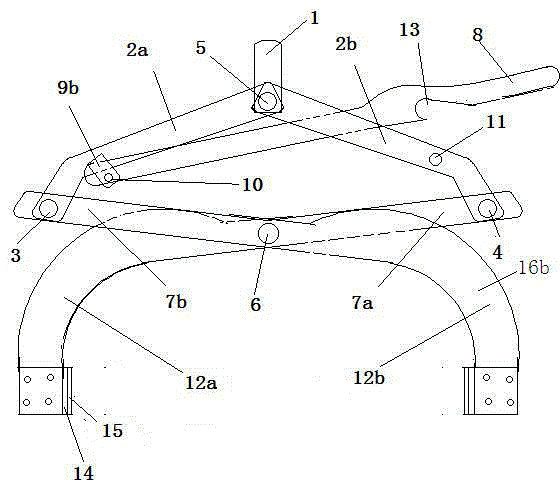

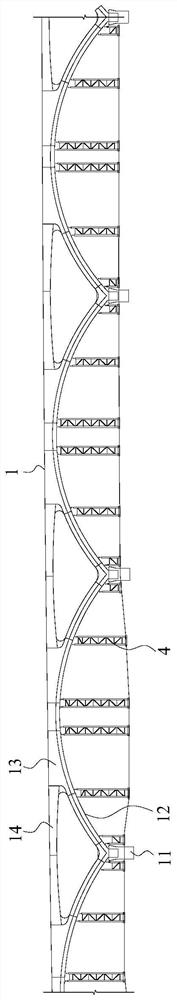

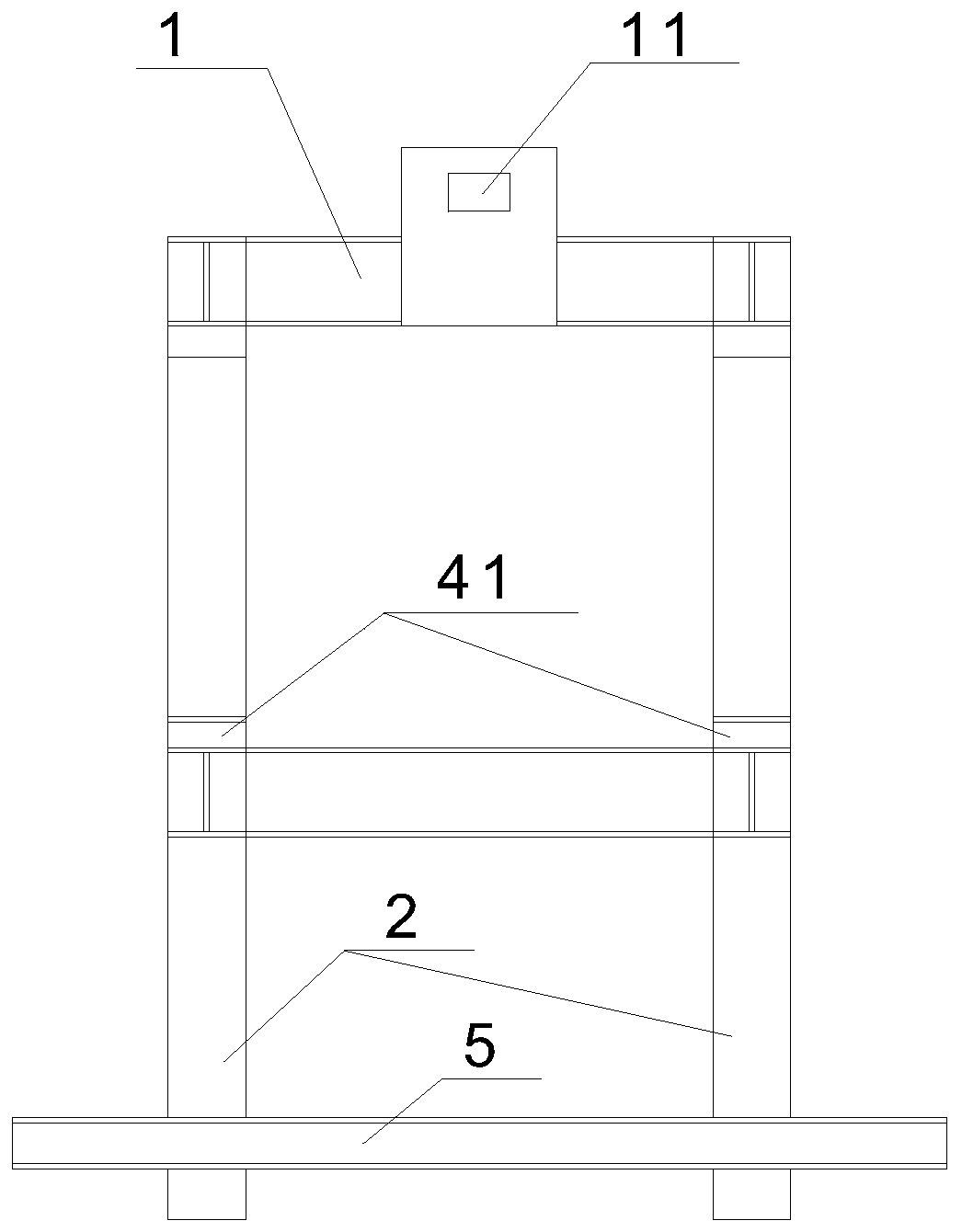

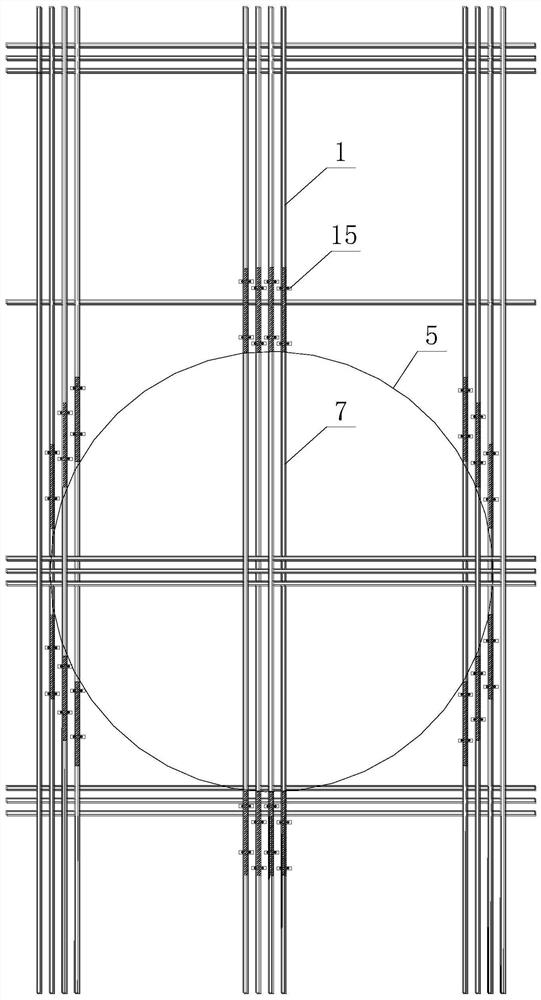

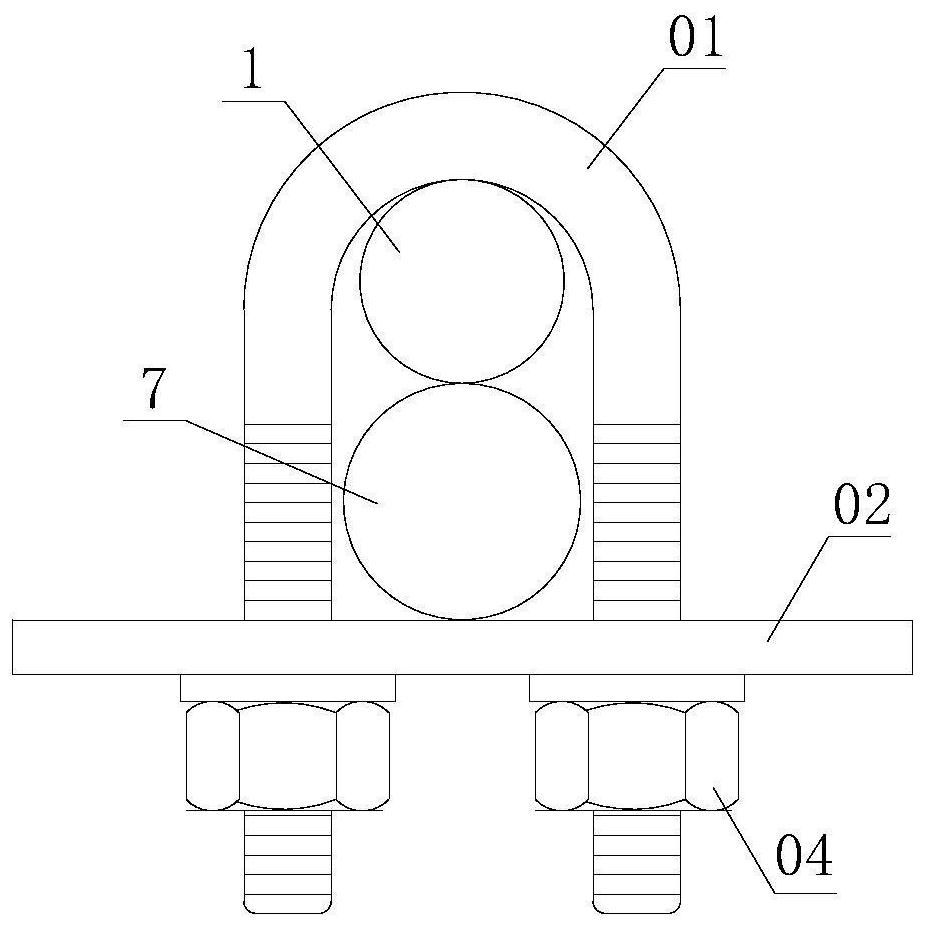

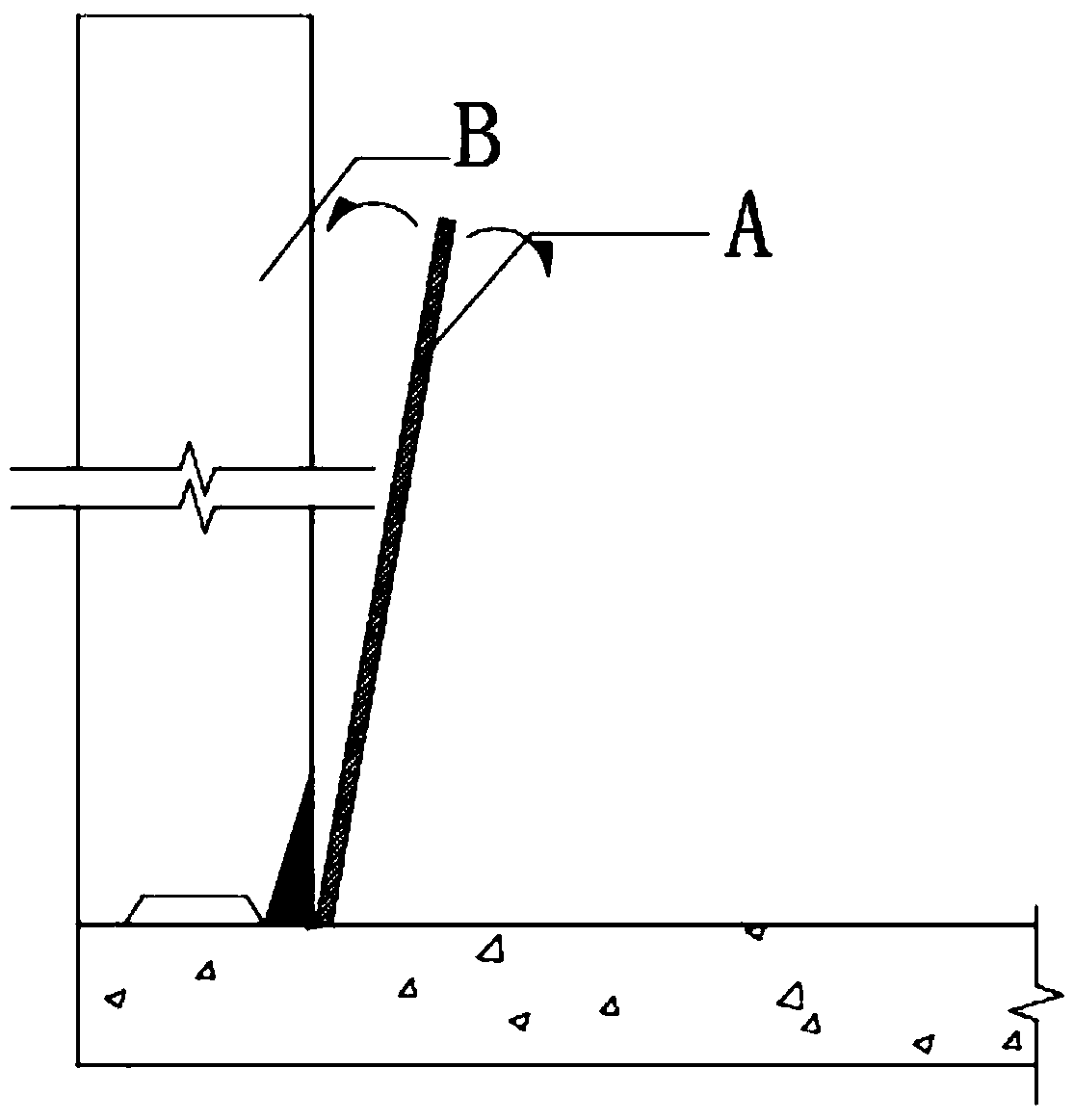

Reinforcing device and method for overweight reinforcement cage of ultra-deep underground diaphragm wall

InactiveCN109914388AImprove tensile capacityEnsure overall rigidity and hoisting safetyBulkheads/pilesRebarOverweight

The invention relates to a reinforcing device and method for an overweight reinforcement cage of an ultra-deep underground diaphragm wall. The overweight reinforcement cage is provided with a liftingpoint U-shaped rib, a longitudinal main rib and a hoisting point horizontal truss rib. One end of the hoisting point horizontal truss rib is fully welded with the lifting point U-shaped rib and the longitudinal main rib, and the other end is fully welded with the hoisting point horizontal truss rib at the position. When the reinforcement cage is hoisted through the L-shaped reinforcing rib, pulling force is transmitted to the longitudinal main rib and a longitudinal truss rib from the hoisting point U-shaped rib and then transmitted to the horizontal truss rib. 10cm full-length welding is adopted between left and right four sealing ribs of the hoisting point horizontal truss rib and a horizontal rib, so that the problem that the sealing rib is infirm in connection and even fall off due tooverlarge stress deformation at the hoisting point and cracking of the welding points of the sealing rib and the horizontal rib when the reinforcement cage is lifted is solved. The method is a reinforcing measure provided in an ultra-deep underground diaphragm wall construction process for solving the problems that when an overweight reinforcement cage is hoisted, stress at a hoisting point is concentrated, deformation easily occurs, a reinforcement welding point is cracked, and the reinforcement cage integrally deforms and is even broken.

Owner:SHANGHAI FOUND ENG GRP

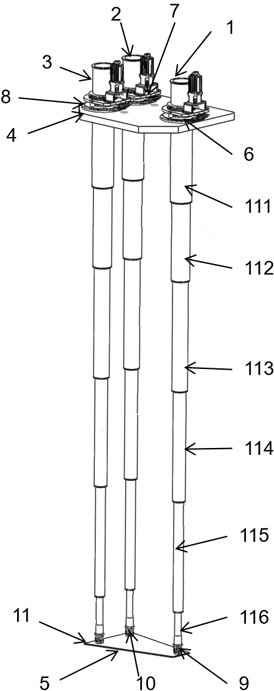

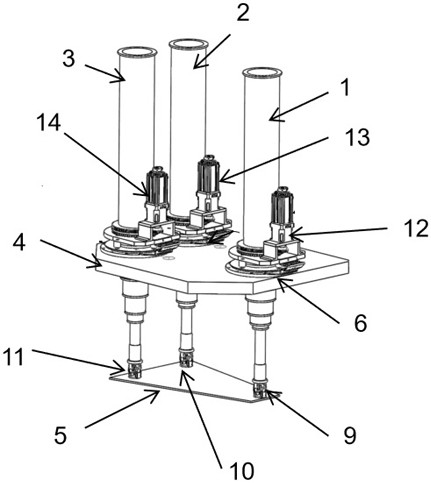

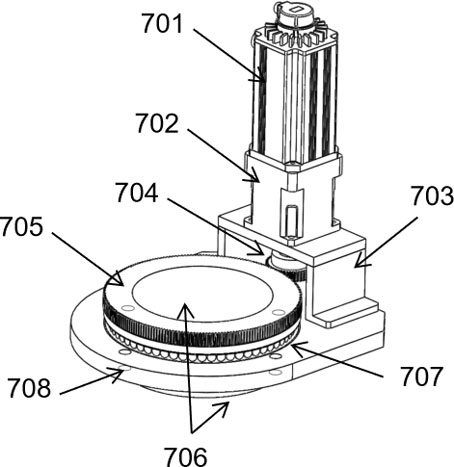

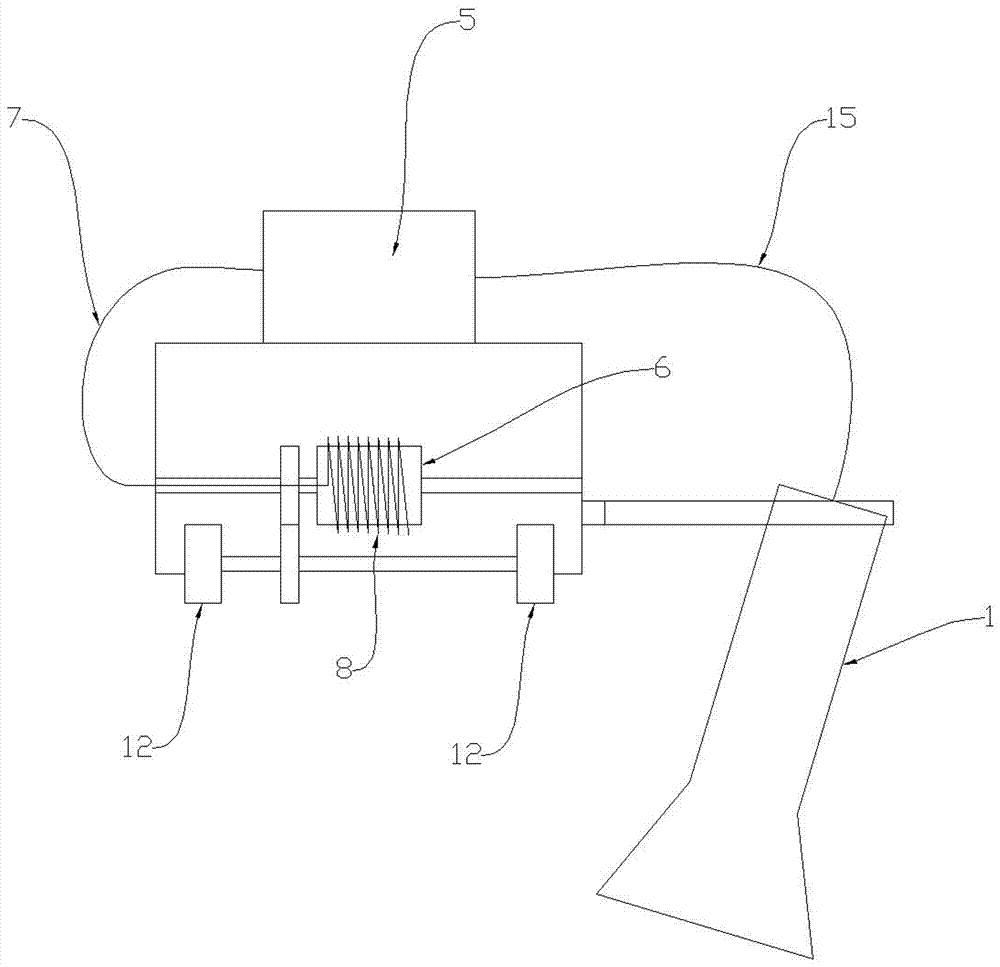

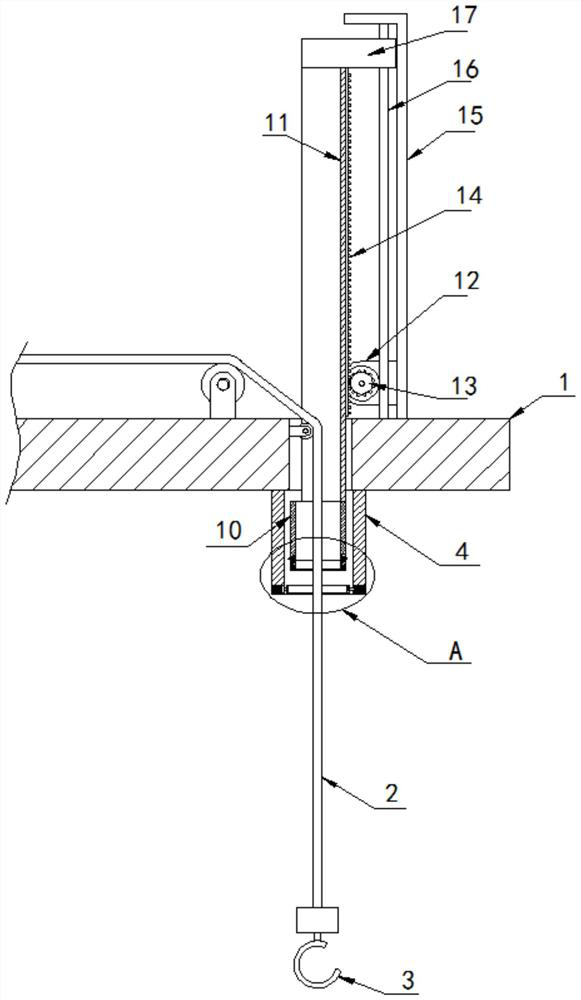

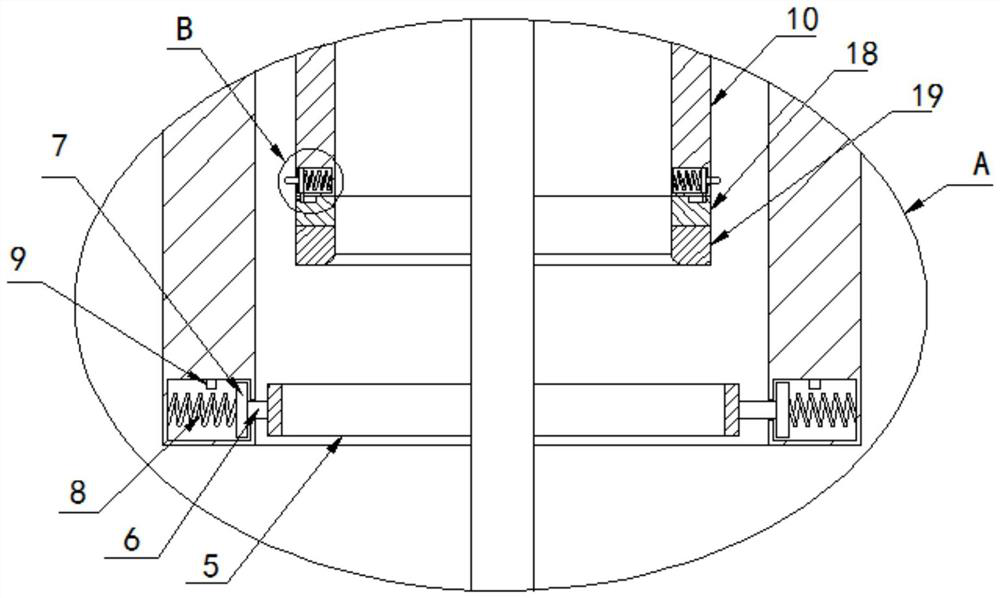

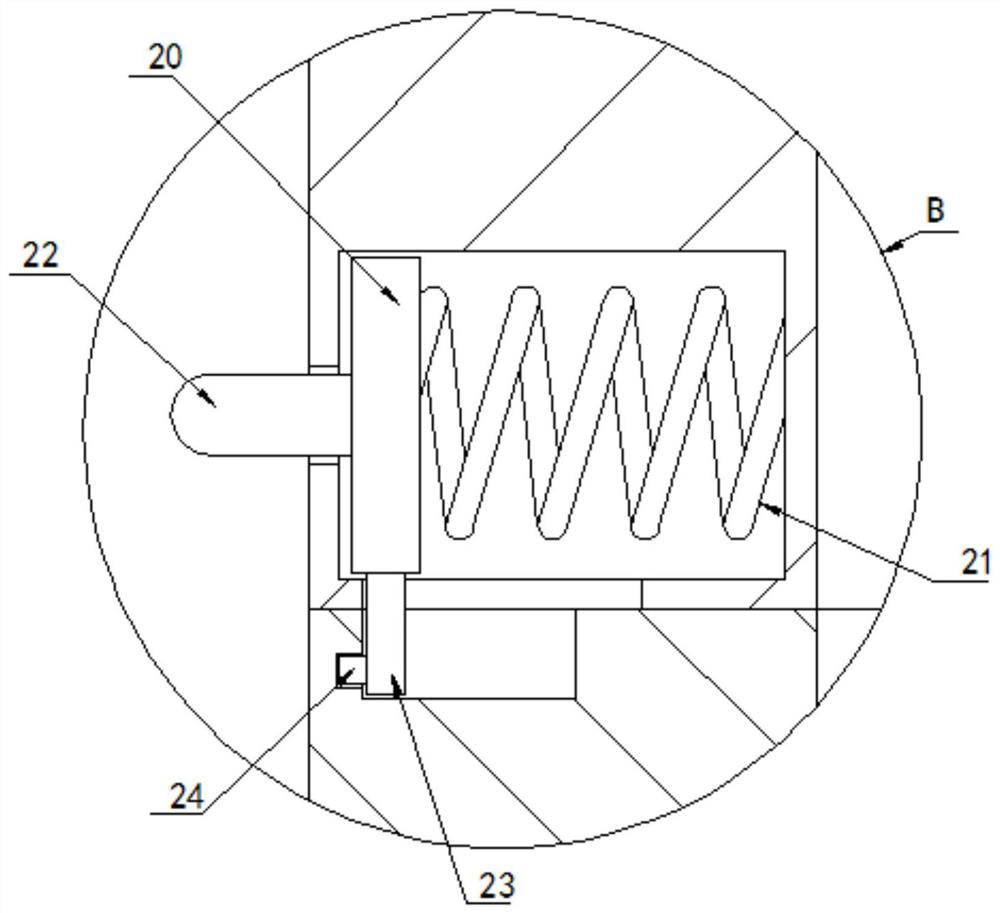

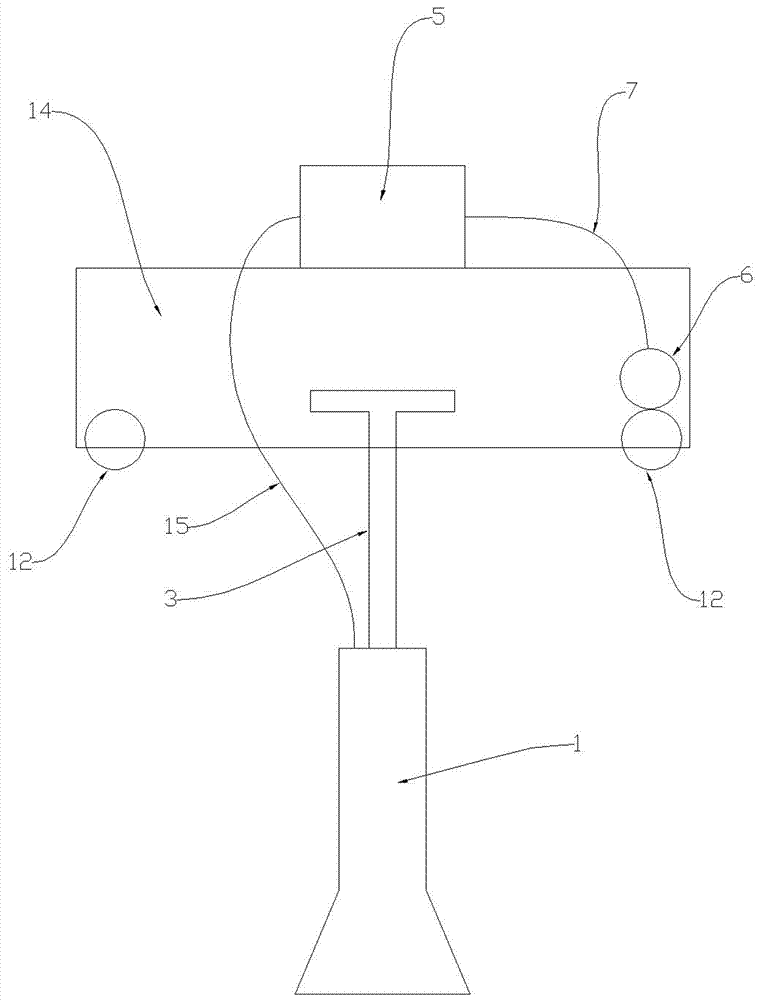

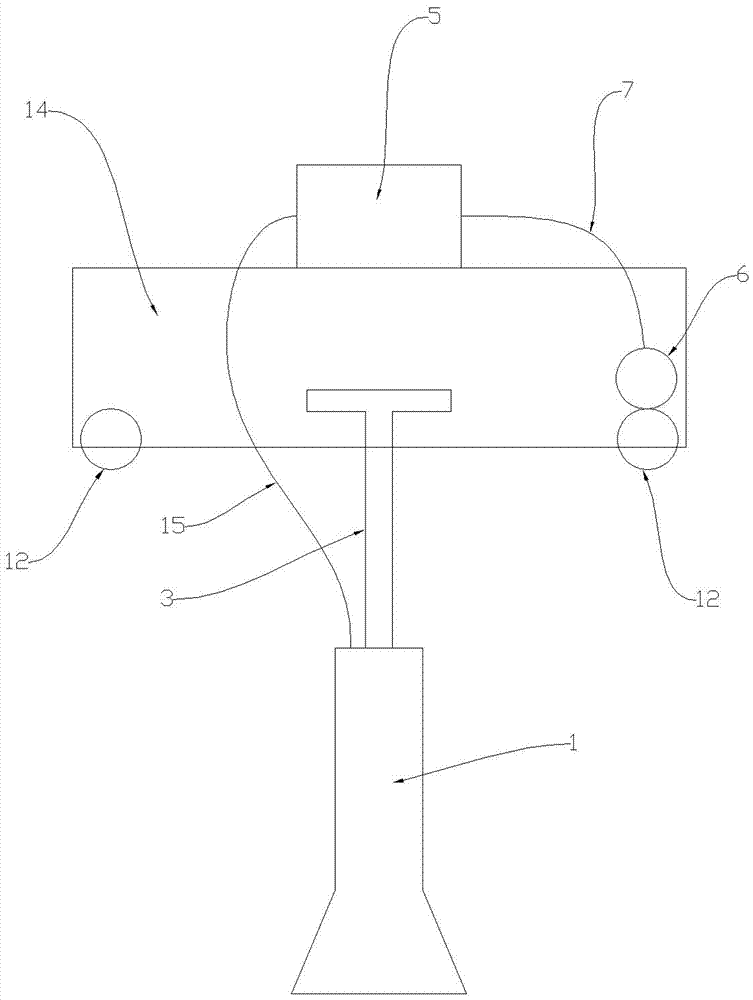

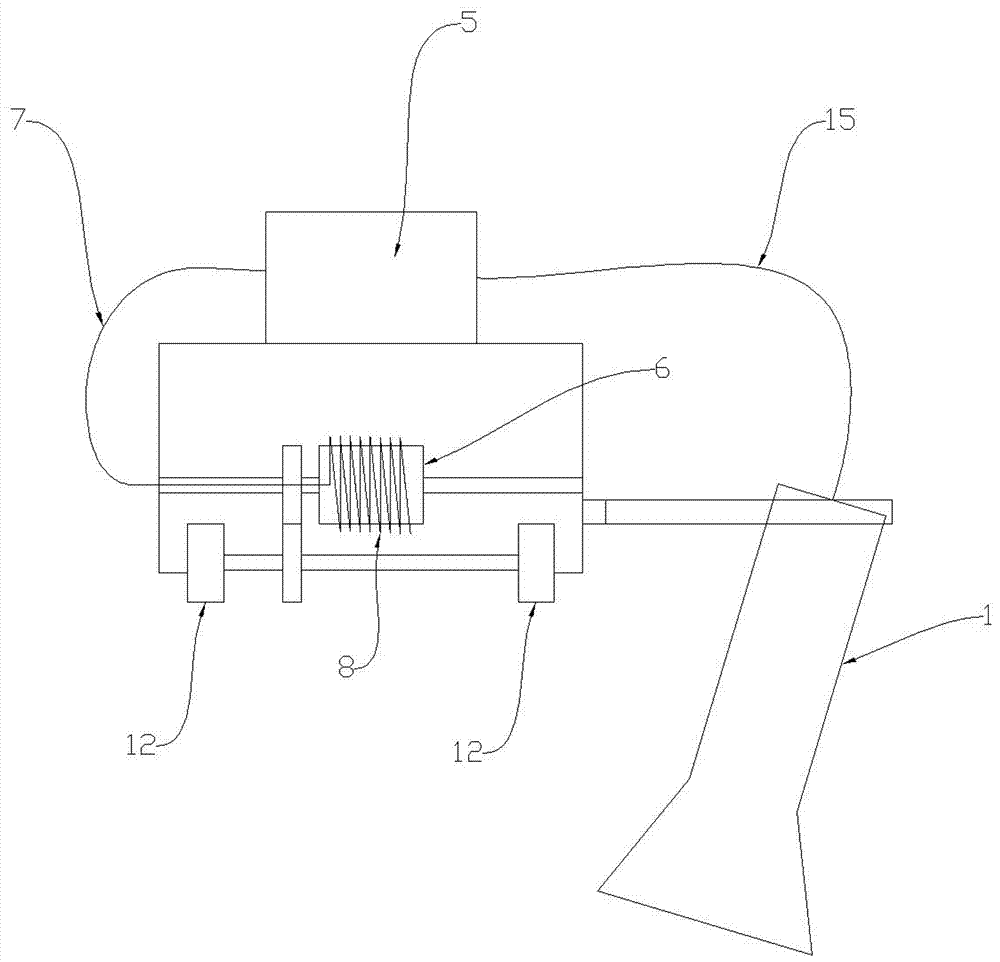

Three-point long-stroke multi-stage trapezoidal lead screw heavy load lifting tool

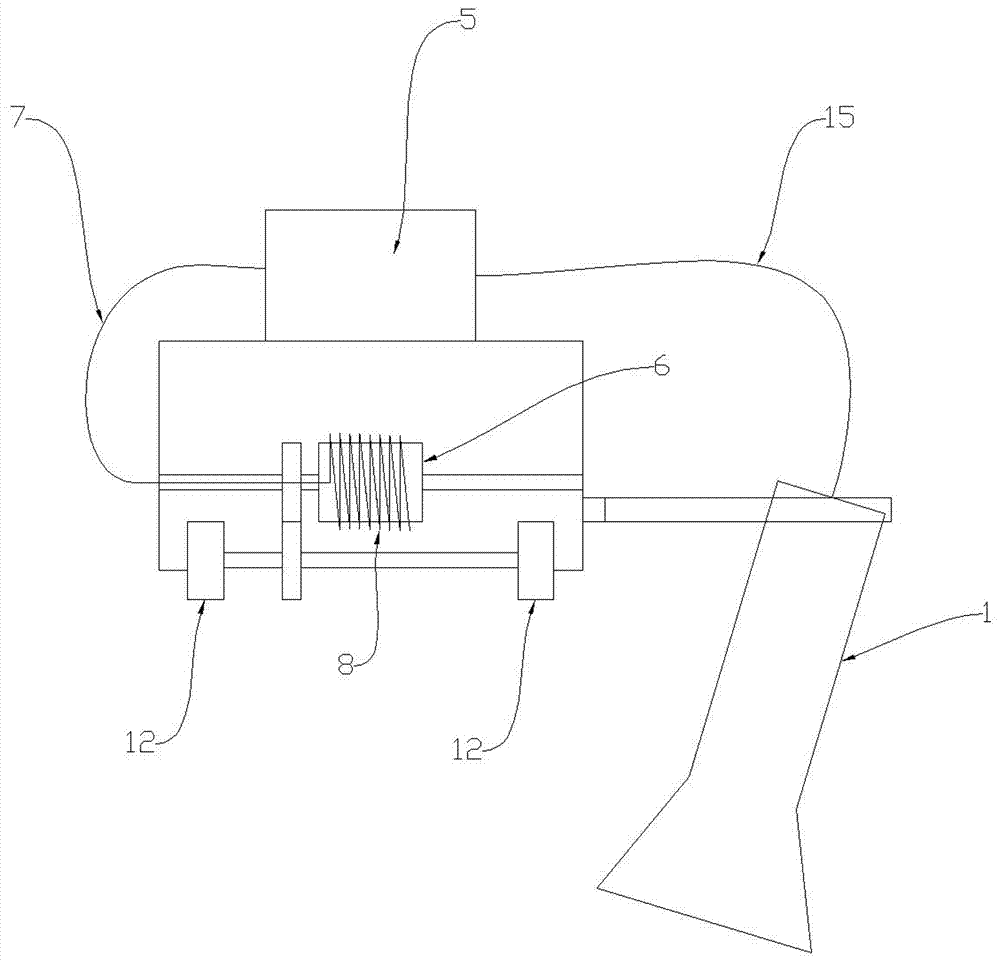

PendingCN111704024AWith self-locking abilityGuarantee the safety of hoistingSafety gearElectric machineryHeavy load

The invention discloses a three-point long-stroke multi-stage trapezoidal lead screw heavy load lifting tool. The three-point long-stroke multi-stage trapezoidal lead screw heavy load lifting tool comprises three heavy load long-stroke lifting multi-stage trapezoidal lead screws, a lifting tool foundation platform, a lifting work platform, three sets of motor drive assemblies, three sets of spherical hinges and three cross joint hinges. Each heavy load long-stroke lifting multi-stage trapezoidal lead screw is mounted on the lifting tool foundation platform through the corresponding motor driveassembly and spherical hinge. The lifting work platform is connected with the lower ends of the three heavy load long-stroke lifting multi-stage trapezoidal lead screws through the three joint hinges. The heavy load long-stroke lifting multi-stage trapezoidal lead screws are driven by the motor drive assemblies to achieve long-stroke telescopic lifting motion, the spherical hinges are connected with the heavy load long-stroke lifting multi-stage trapezoidal lead screws through the motor drive assemblies, and then axial loads of the lifting heavy load long-stroke lifting multi-stage trapezoidal lead screws are borne. The three-point long-stroke multi-stage trapezoidal lead screw heavy load lifting tool solves the problems of vertical narrow space heavy loads, load distribution and motion precision well.

Owner:无锡智航控制技术有限公司

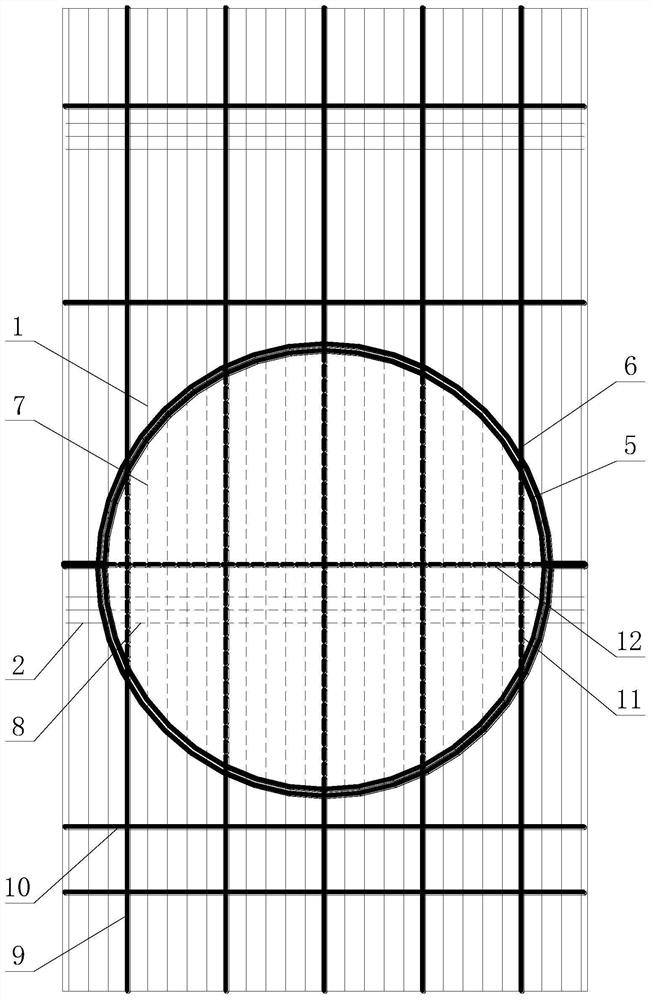

Unilateral glass rib-reinforcement cage structure for shield tunnel portal diaphragm wall

ActiveCN110080296AMeet the bending capacityMeet the force requirementsArtificial islandsUnderwater structuresGlass fiberRebar

The invention discloses a unilateral glass rib-reinforcement cage structure for a shield tunnel portal diaphragm wall. The structure comprises an underground diaphragm wall reinforcement cage, a tunnel portal steel ring is tightly attached to and connected to the soil backing side face of the underground diaphragm wall reinforcement cage, an annular reinforcement truss which is concentric with thetunnel portal steel ring is connected between a soil facing side face and a soil backing side face of the underground diaphragm wall reinforcement cage, the annular reinforcement truss is located onthe periphery of the tunnel portal steel ring, the parts, located on the inner periphery of the tunnel portal steel ring, of soil facing side vertical reinforcements striding over the tunnel portal steel ring are replaced by vertical glass fiber bars, and the parts, located on the inner periphery of the tunnel portal steel ring, of soil facing side horizontal reinforcements striding over the tunnel portal steel ring are replaced by horizontal glass fiber bars. The tunnel portal steel ring is used for receiving and pre-burying a shield tunneling machine when serving as a main body structure, and the arranged annular reinforcement truss is used for ensuring that the glass fiber bars are not influenced by gravity to be infinitely broken when the reinforcement cage is lifted, so that the lifting safety of the reinforcement cage can be ensured, and the stress requirement of a wall body can be met.

Owner:CHINA TIESIJU CIVIL ENG GRP CO LTD

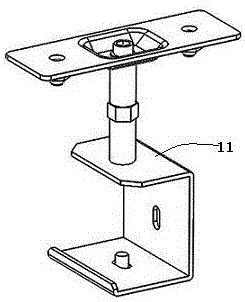

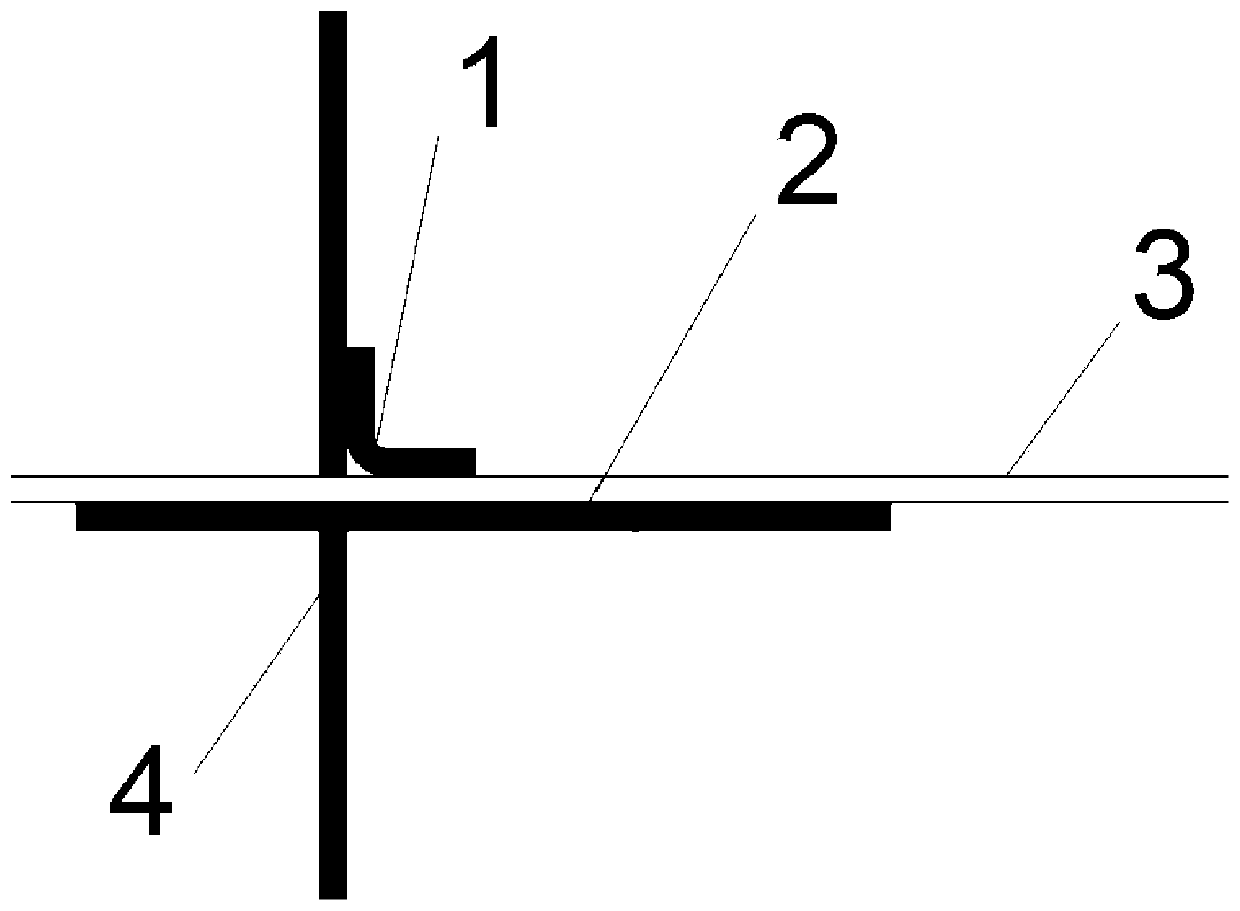

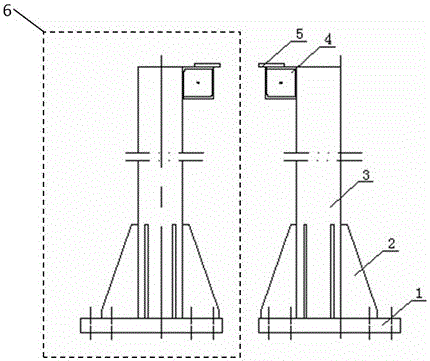

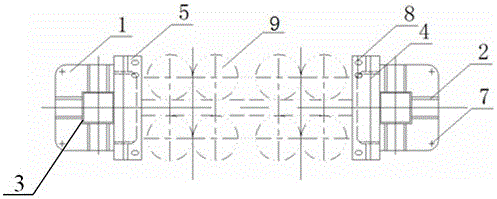

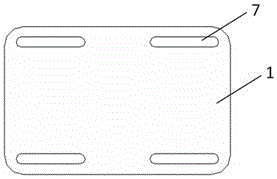

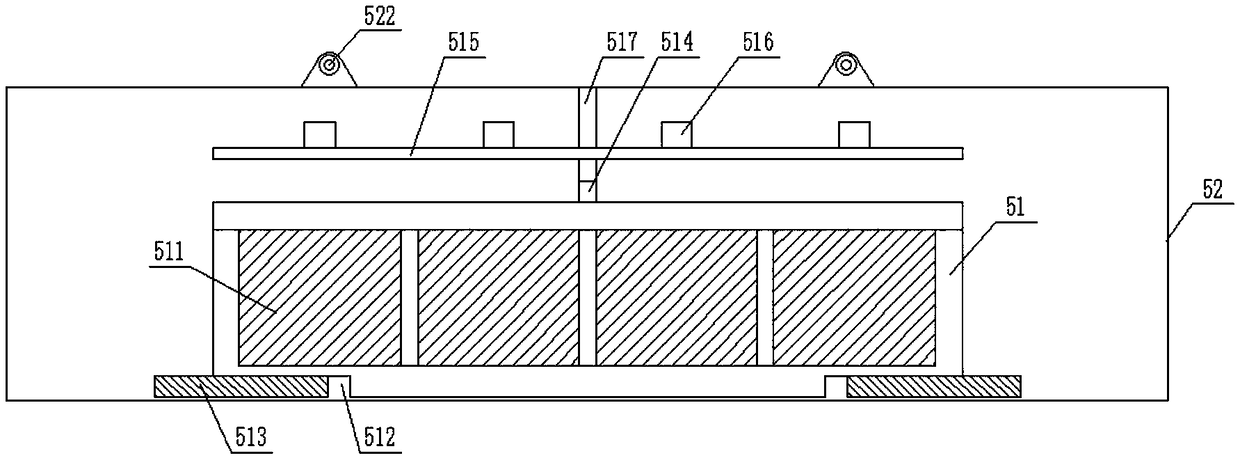

Adjustable supporting device for equipment mounting frame

InactiveCN105782681AGuaranteed Width RequirementsGuarantee the safety of hoistingMachine supportsEngineeringChassis

The invention provides an adjustable supporting device for equipment mounting frame. The adjustable supporting device for the equipment mounting frame comprises two groups of supporting mechanisms which are arranged in a mirror symmetry manner, wherein each supporting mechanism is composed of a chassis; an upright column is eccentrically welded on each chassis; two ribbed slabs are welded on each side wall of each upright column; a supporting square tube is welded to one side wall of the upper end of each upright column and is horizontally arranged; a supporting plate is welded to the upper top surface of each supporting square tube; one side of each supporting plate extends out of the upper top surface of the corresponding supporting square tube and hangs in the air; and a plurality of mounting holes are formed in one side, extending out of the corresponding supporting square tube, of each supporting plate. According to the adjustable supporting device for the equipment mounting frame, the mounting conditions of equipment mounting frames in different machine types can be met; four through grooves are formed in each chassis to be matched with four ground screws of each fixing bottom plate, so that the mounting length can be adjusted; the ribbed slabs on the corresponding upright columns ensure the hoisting safety; the mounting holes formed in the corresponding supporting plates meet the requirements for widths of the equipment mounting frames in different machine types; and in the premise of meeting the using function, a test site is saved, and the maximum test capability of a limited test site can be exerted during test in a large scale.

Owner:RES INST OF PHYSICAL & CHEM ENG OF NUCLEAR IND

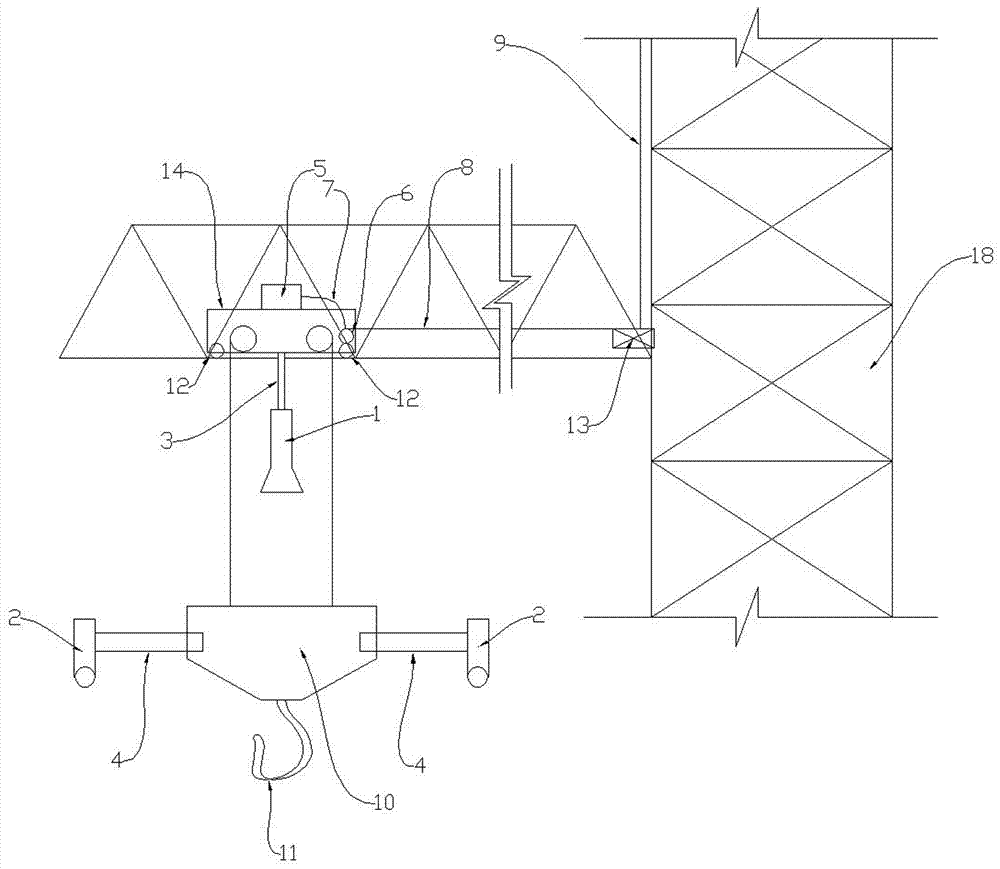

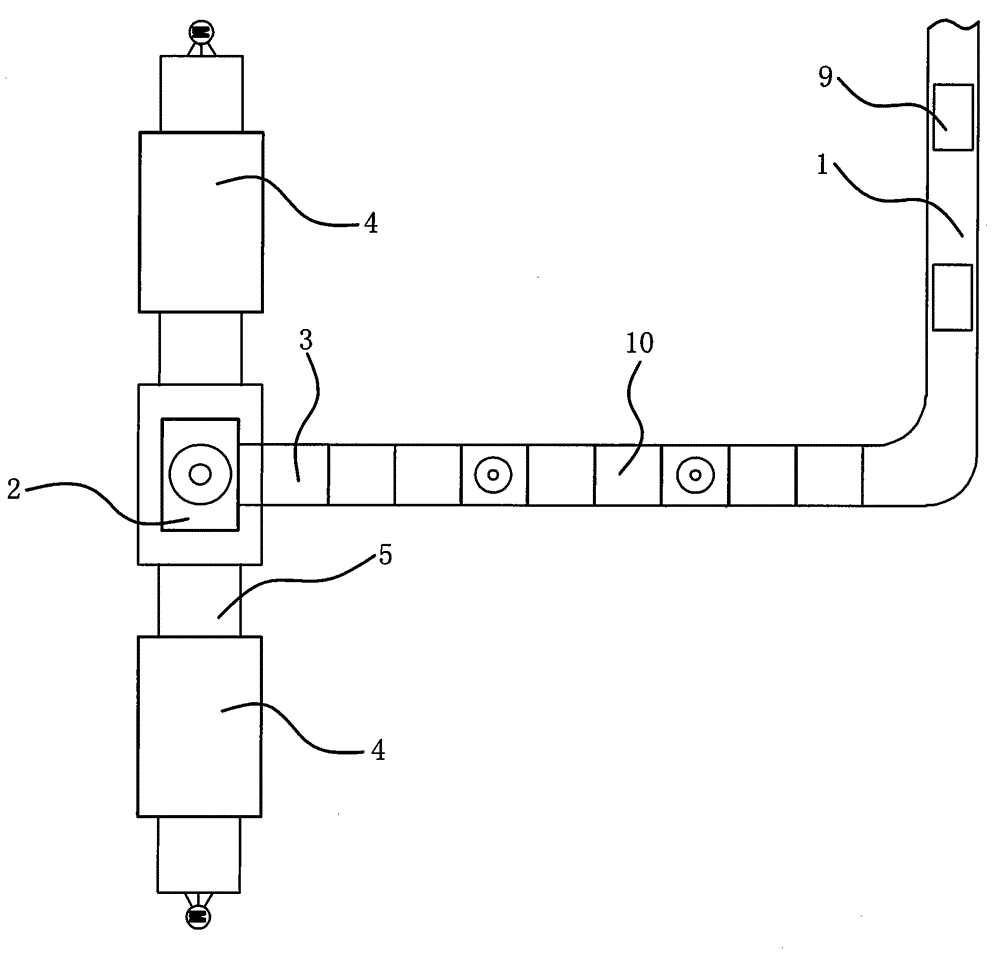

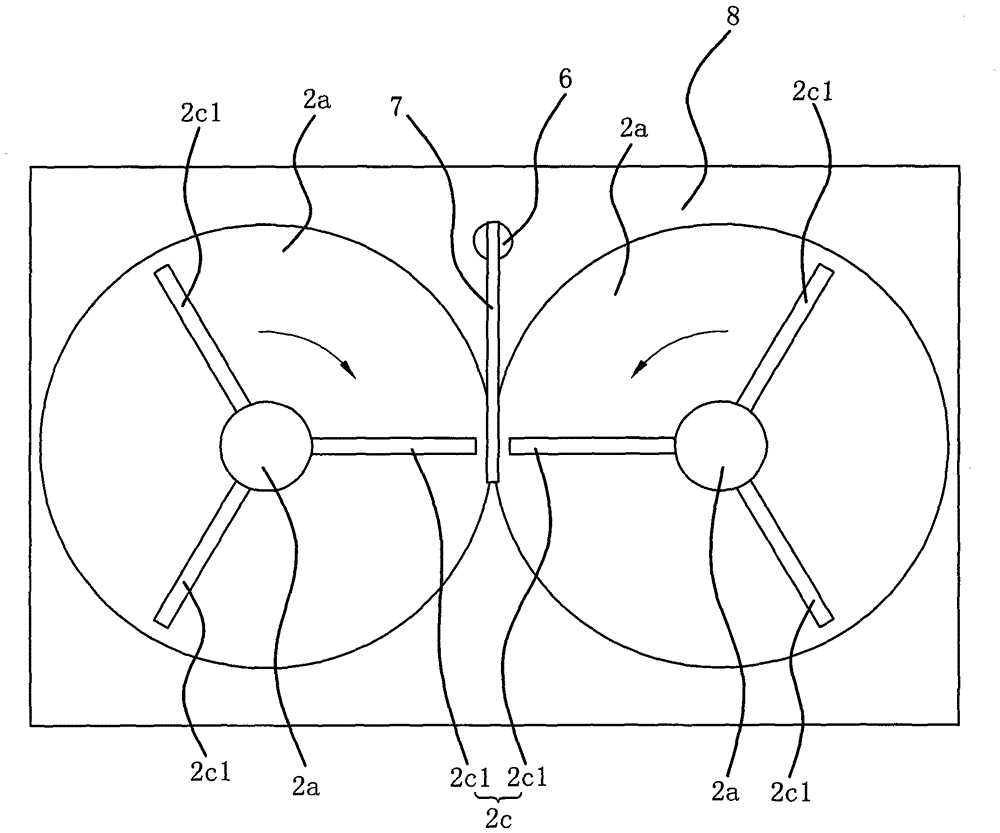

Multifunctional video monitoring system for tower crane

InactiveCN107140539AGuarantee the safety of hoistingLoad-engaging elementsVideo monitoringSimulation

The invention discloses a multifunctional video monitoring system for a tower crane. The multifunctional video monitoring system for the tower crane is mainly used for the tower crane in the field of constructional engineering. The driver of the tower crane can observe the condition of a dead zone on the ground through a video monitoring system, thereby ensuring safe hoisting. The multifunctional video monitoring system for the tower crane is composed of the video monitoring system and a dead zone hoisting position search system, wherein the video monitoring system is mainly composed of a camera A, a camera B and the like; the dead zone hoisting position search system is mainly composed of a video system, a GPS position finder A, a data processing module and a GPS position finder B; and the main working principle is as follows: when the driver of the tower crane comes across a dead zone hoisting position which cannot be seen, the dead zone hoisting position is searched by the dead zone hoisting position search system and displayed in a display screen, the driver of the tower crane operates the tower crane to transfer a hoisting hook to the dead zone hoisting position, and then the ground condition of the dead zone hoisting position, the surrounding condition of the hoisted object, and the binding in-place condition of the hoisting hook and a steel wire rope are displayed by the video monitoring system, and safe hoisting is carried out.

Owner:JINGMEN CHUANGJIA MACHINERY TECH CO LTD

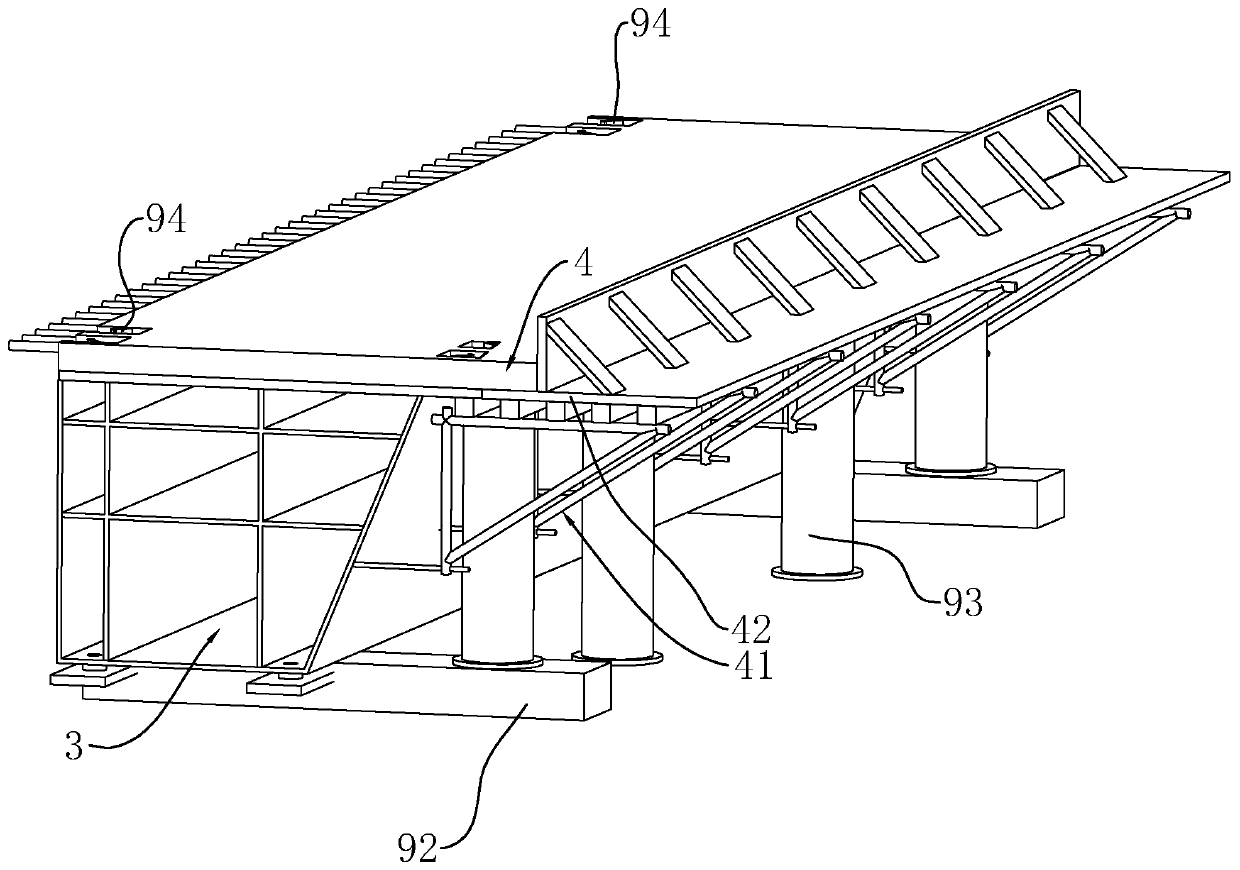

Construction method of reinforced concrete box girder

InactiveCN109837838AGuarantee the safety of hoistingShorten the construction periodBridge erection/assemblyReinforced concreteBridge deck

The invention relates to a construction method of a reinforced concrete box girder, which comprises the following construction steps: 1, placing a steel box girder body on the ground, and pouring andmaintaining bridge deck concrete and flange plate concrete on the ground; 2, installing scaffold units on the ground on the same outer side faces of two bridge piers, and the scaffold units extend into the bottoms of flange plates of a first reinforced concrete box girder; 3, hoisting the first reinforced concrete box girder, loosening hooks, stressing the scaffold units, supporting the flange plates, and therefore preventing the reinforced concrete box girder from overturning due to the eccentric effect; and 4, hoisting the second reinforced concrete box girder, wherein the second reinforcedconcrete box girder is not loosened after being in place, and using a long-strip angle steel to weld with two steel box girder bodies, so that the two steel box girders are pulled and connected into awhole, and the second reinforced concrete box girder is prevented from overturning. The construction method has the technical effects that the construction period of the reinforced concrete box girder is short, and hoisting is safe.

Owner:BEIJING NO 2 MUNICIPAL CONSTR ENG LTD

Bundled steel tube lifting appliance

InactiveCN104787665AShorten the lifting timeLifting speed is fastLoad-engaging elementsAbnormal shapesEngineering

The invention discloses a bundled steel tube lifting appliance, and belongs to the technical field of steel tube hoisting tools. The lifting appliance comprises a cross beam, wherein a lifting rope is connected with the upper part of the middle of the cross beam, two lifting claw mechanisms are connected with the lower parts of the two ends of the cross beam, the upper part of the lifting claw mechanism is an abnormal-shape rhombus structure formed by hinging and connecting four sides, and four abnormal-shape rhombus sides are connected through articulated shafts; the connecting line of the upper and lower articulated shafts in the opposite angles of the rhombus is in the vertical direction, the connecting line of the left and right articulated shafts is in the horizontal direction, a lifting ring is connected with the upper articulated shaft at the uppermost end, a locking rod is hinged to one of two upper sides of the abnormal-shape rhombus, and a locking gap is formed in the locking rod. By adopting the bundled steel tube lifting appliance, one person can operate a crown block or crane to lift bundled steel tubes, so that the lifting speed of the steel tubes is increased, the human cost is reduced, and the lifting safety is guaranteed.

Owner:ANYANG ZHONGTAI PIPES

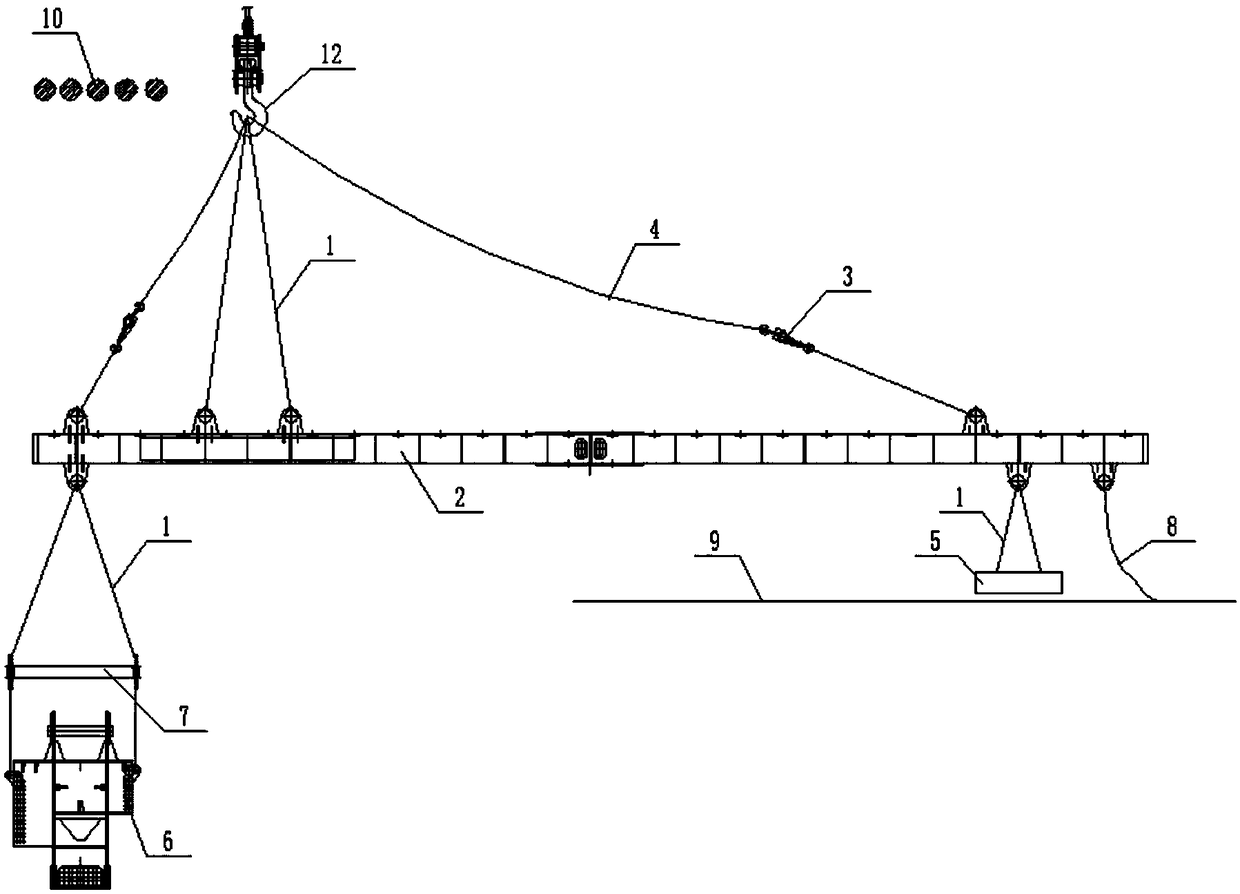

Weighbeam type balance beam hoisting tool and method for hoisting steel beam component through same

ActiveCN109335949ALarge adjustment rangeFlexible and convenient installationLoad-engaging elementsEngineering

The invention discloses a weighbeam type balance beam hoisting tool and a method for hoisting a steel beam component through same. The weighbeam type balance beam hoisting tool comprises a balance beam, a C-beam, a balance weight, a pair of safety steel wire ropes and a cable wind rope, wherein the balance beam is connected through a hoisting steel wire rope; the C-beam is connected to the steel beam component, and the C-beam is connected to one end of the balance beam through the hoisting steel wire rope; the balance weight is connected to the other end of the balance beam through the hoisting steel wire rope; the upper ends of the safety steel wire ropes are connected to a boom hook, and the lower ends of the safety steel wire ropes are correspondingly connected to two ends of the balance beam; the safety steel wire ropes are in a slightly loose state; and one end of the cable wind rope is connected to the other end of the balance beam, and the other end of the cable wind rope is arranged on a bridge. According to the weighbeam type balance beam hoisting tool, the moment balance theory is utilized; the balance is realized through the balance beam based on the length and weight ofthe component and an actuating arm of the balance weight, so that the steel beam component can be mounted, and the component is successfully prevented from being intersected with an upper barrier space, and as a result, the stable hoisting is realized, and as a result, the component hoisting safety is ensured, and the circuit is smooth.

Owner:CHINA COMM 2ND NAVIGATIONAL BUREAU 2ND ENG +1

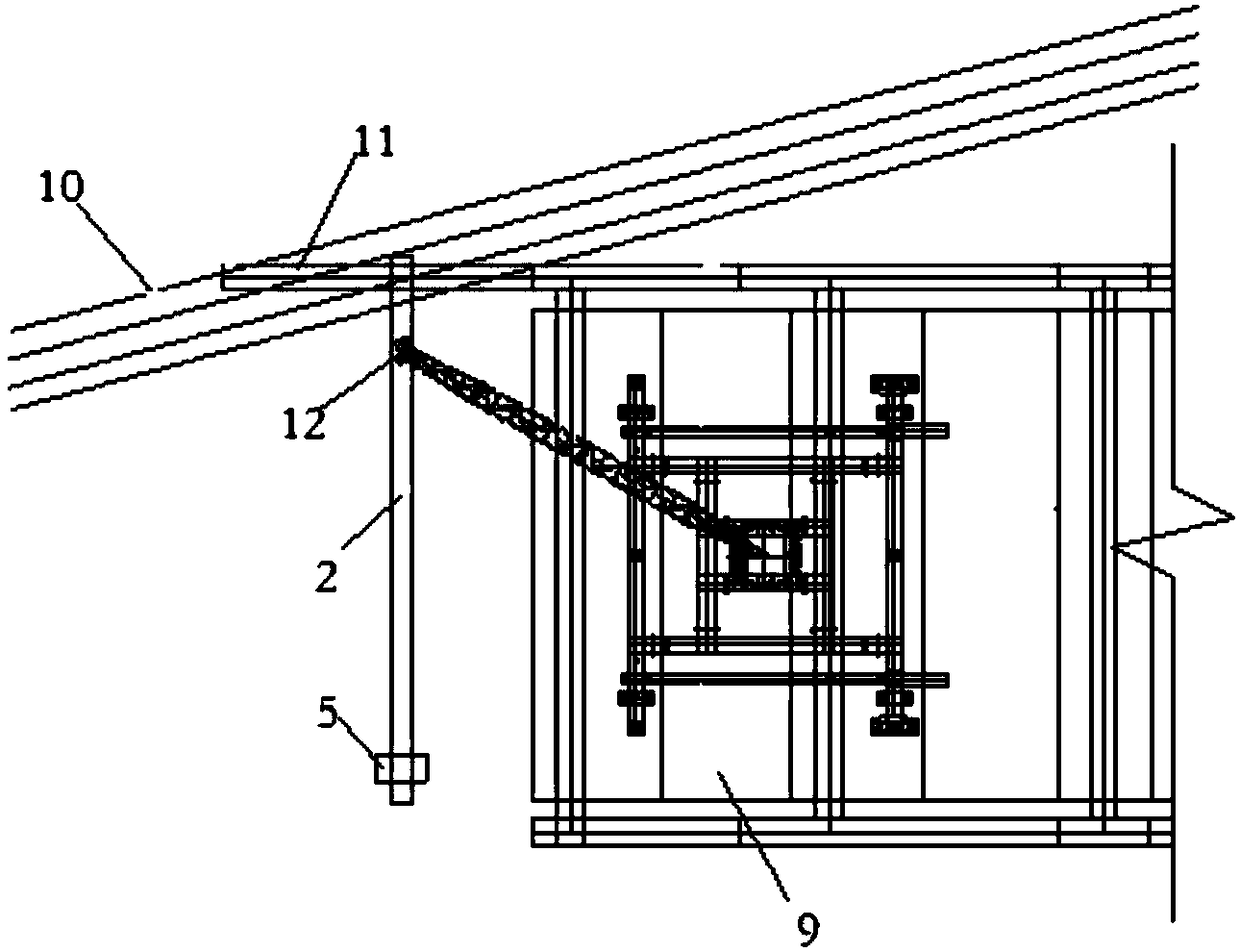

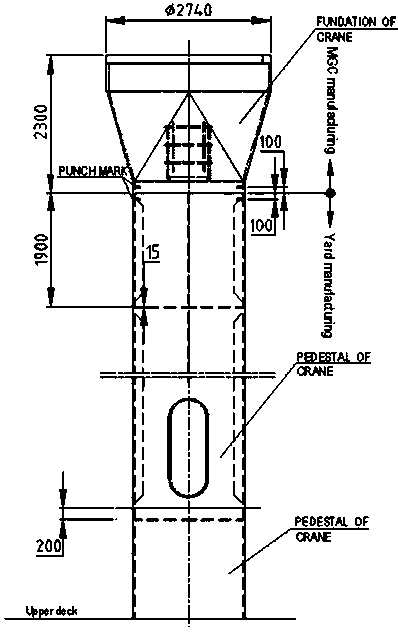

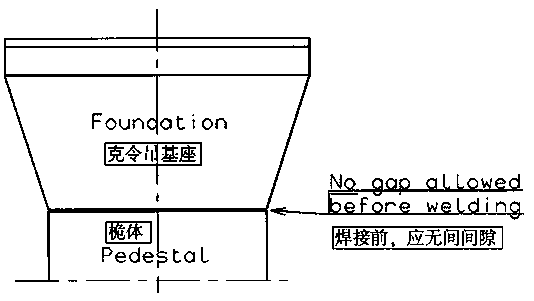

Crane installation process

InactiveCN110153599ASimplify the installation processReduce construction difficultyWelding/cutting auxillary devicesVessel designingDiagonalEngineering

The invention relates to a crane installation process. The crane installation process includes: step 1, obtaining planeness of a flange plane of a crane base seat, obtaining the length, the width andthe diagonal size of the crane base seat and crane mast body connection ports, and detecting deviation value between the crane base seat and each crane mast body connection port; step 2, hoisting a mast body, fixing the mast body on a ship body through welding, surveying and scribing a 100 horizontal reference line on a folding opening of an upper port and completing drift pin marking after construction completes, hoisting the crane base seat, and surveying and scribing the other 100 horizontal reference line on a folding opening of a lower port and completing drift pin marking; step 3, aftercompleting inspection of the size of the crane base seat and confirming that accuracy of the size of the crane base seat meets requirements, butting the crane base seat against the mast body, and placing and welding the crane base seat and the mast body in the vertical direction. The crane installation process is simple, can directly hoist the components onto the ship body for installation, reduces construction difficulty, and improves construction efficiency, and by adopting the above welding method for welding, quality of a welding seam can be guaranteed, and hoisting safety is ensured.

Owner:ZHEJIANG INT MARITIME COLLEGE

Automatic stacking and assembly system

InactiveCN104787584BReduce mechanical failureLower the altitudeStacking articlesAutomatic tuningPackaging machine

The invention provides an automatic bag folding and integrated packaging system, and belongs to the technical field of works. The automatic bag folding and integrated packaging system solves the problems that an existing bag folding and integrated packaging machine is low in working efficiency, and many workers are needed. The automatic bag folding and integrated packaging system comprises a rack and a bag folding trolley. The rack is provided with a horizontal roller conveying line, a falling control device with a supporting plate and used for controlling falling of bags and a high-speed conveying line connected with the roller conveying line in series and capable of conveying the bags to fall on the supporting plate. The bag folding trolley is located below the falling control device. According to the automatic bag folding and integrated packaging system, the roller conveying line can adjust the postures and intervals of the bags automatically, and workers in the corresponding processes are saved; the high-speed conveying line guarantees that the bags totally fall on the supporting plate, and the postures of the bags falling on the supporting plate are the same, and thus the corresponding adjusting personnel is saved; at the bag folding trolley, only one lifting worker is needed to arrange a hook ring for lifting the bags in a lifting hook of a lifting device in a sleeving mode, and the automatic bag folding and integrated packaging system has the advantage that the workers required by operation are less.

Owner:林文彬

Safety early warning method and equipment for hoisting machinery

The invention relates to the technical field of hoisting machines, and discloses a hoisting machinery safety early warning method and equipment, the hoisting machinery safety early warning equipment comprises a hoisting arm, a hoisting rope and a hook, an outer sleeve is fixedly arranged at the bottom of the hoisting arm, two arc-shaped plates are symmetrically arranged in the outer sleeve, the hoisting rope penetrates through the space between the two arc-shaped plates, and connecting rods are fixedly arranged on the sides, away from each other, of the two arc-shaped plates; first cavities are formed in the two sides of the outer sleeve correspondingly, extrusion blocks are arranged in the two first cavities correspondingly, first springs are fixedly arranged on the side walls of the extrusion blocks, the other ends of the first springs are fixedly connected with the side walls of the first cavities correspondingly, touch sensors are fixedly arranged on the tops of the two first cavities correspondingly, and the extrusion blocks can make contact with the touch sensors. The ends, away from the arc-shaped plate, of the two connecting rods penetrate into the two first cavities correspondingly and are fixedly connected with the side walls of the two extrusion blocks correspondingly. According to the safety early warning method and equipment for the hoisting machinery, the shaking amplitude of the hoisting rope can be limited, and the danger of hoisting an object is reduced.

Owner:京杭运河施桥船闸至长江口门段航道整治工程项目管理办公室

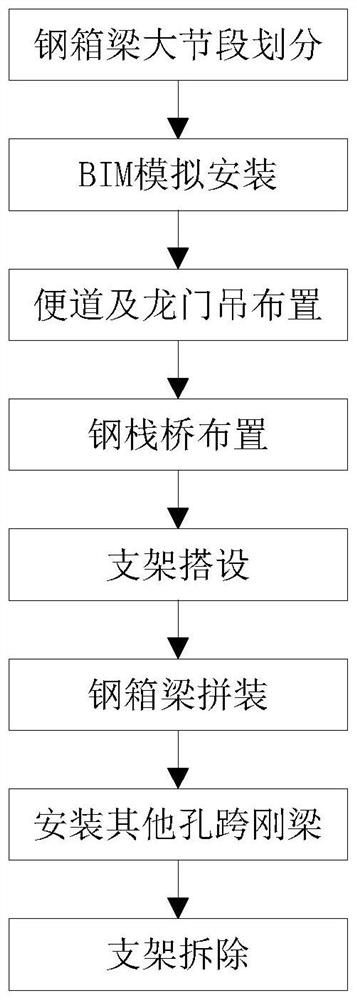

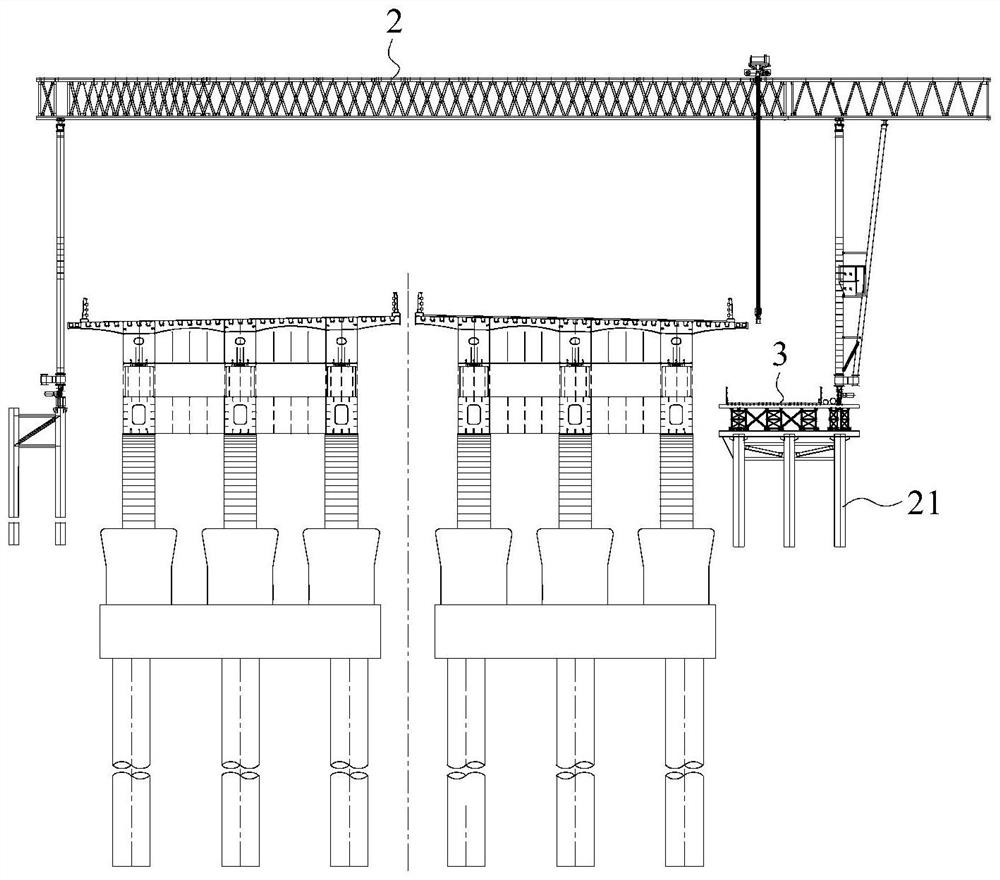

Construction method of large-span steel box continuous arch bridge

PendingCN114790687AReduce the amount of welding workGuarantee the quality of the projectBridge erection/assemblyBridge materialsArchitectural engineeringEngineering

The invention discloses a construction method of a large-span steel box continuous arch bridge. The construction method comprises seven steps of dividing large sections of steel box girders, arranging shortcuts and gantry cranes, arranging a steel trestle, erecting a bracket, assembling the steel box girders, mounting other hole span steel girders and dismounting the bracket. According to the steel box girder, large-section splicing, flat car transportation and gantry crane hoisting are completed in a splicing field, the welding work amount of field installation is reduced, the project quality is guaranteed, before installation construction, through the BIM virtual installation technology, the problems occurring in the installation process of the large sections of the steel bridge are found out, an optimal correction scheme is given, and the construction efficiency is improved. Field work is reduced, and construction quality is improved.

Owner:河北省高速公路延崇管理中心(河北省高速公路京雄管理中心) +1

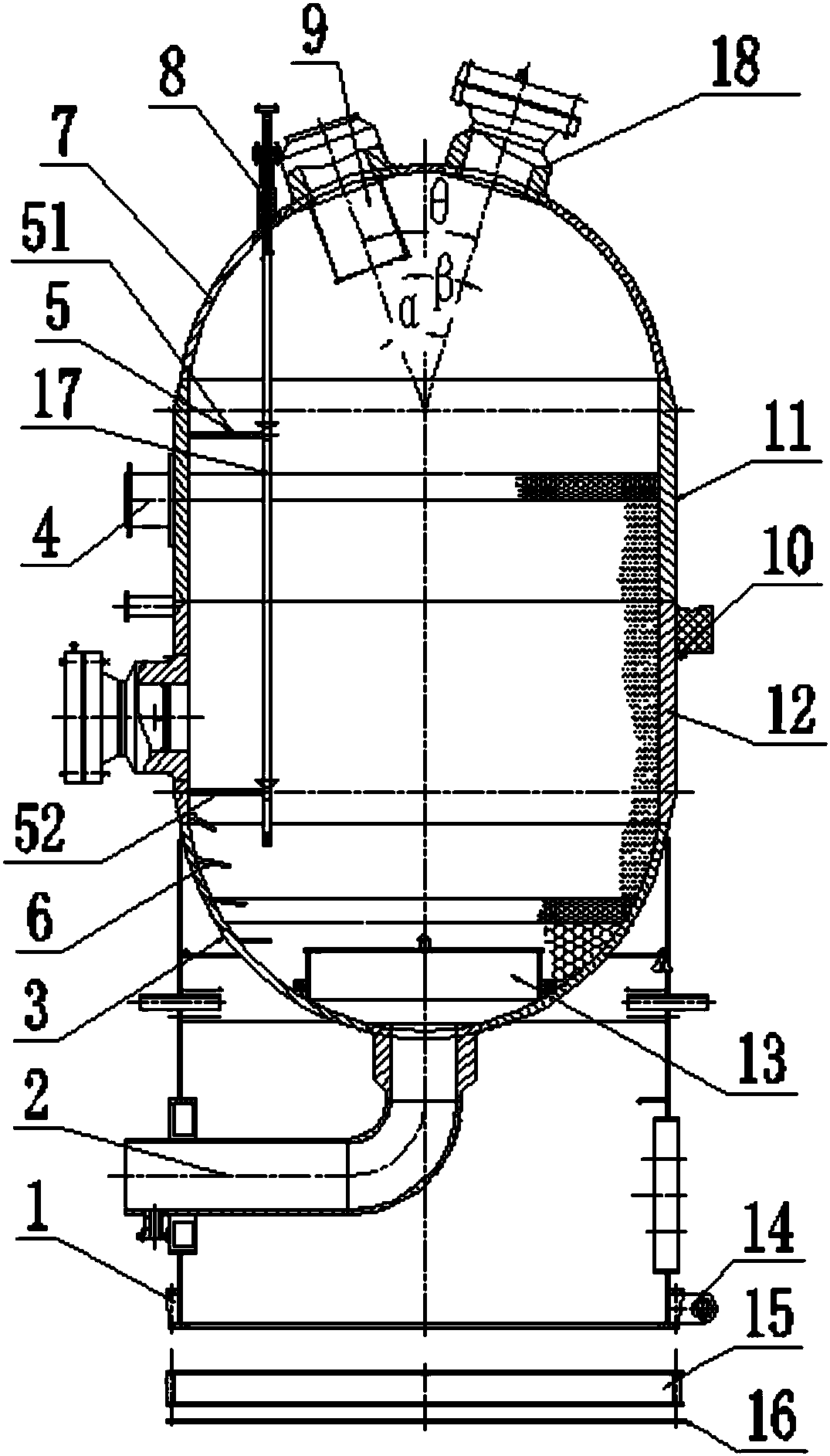

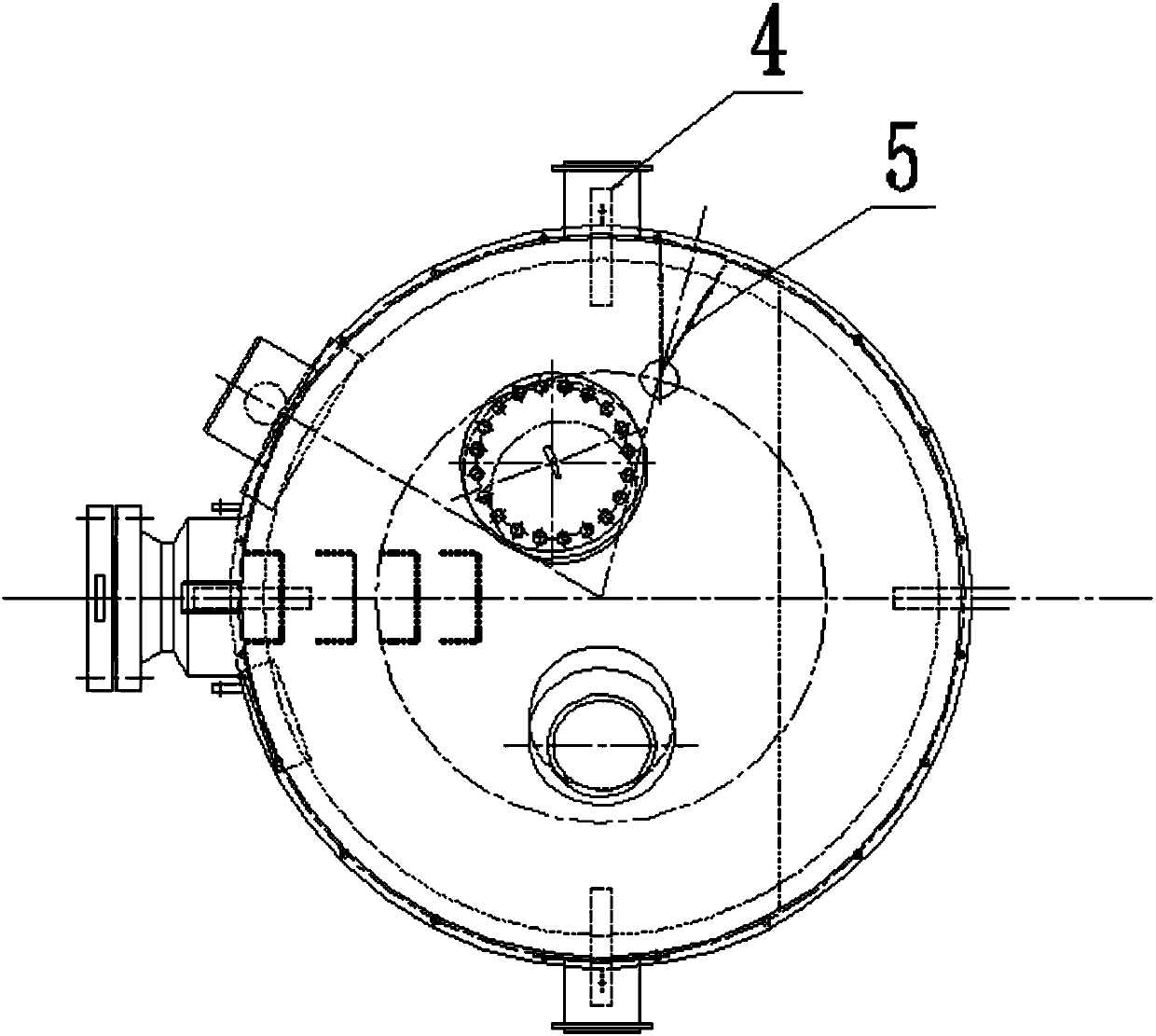

Hydrogenation reactor for petrochemical engineering

InactiveCN108014720AGuarantee the safety of hoistingGuarantee the stability of hoistingHydrocarbon oil crackingChemical/physical processesPetrochemicalThermocouple

The invention discloses a hydrogenation reactor for petrochemical engineering and belongs to the technical field of petrochemical engineering. An inlet distributor is fixed on an upper spherical cover, a catalyst entering the hydrogenation reactor is fully dispersed and diffused, full contact between crude oil and the catalyst is realized, the crude oil is fully cracked and decomposed in a refining device, and the effective utilization rate of the catalyst can be increased. An outlet collector is placed at the bottom of a lower spherical cover and can recycle the catalyst which is not fully utilized by the crude oil, effective utilization of the catalyst is further improved, the crude oil refining cost is reduced, and the crude oil refining benefits are increased. A longer thermocouple isreliably fixed on the inner wall of the hydrogenation reactor in an inner extension tube support manner, the structural strength of a thermocouple sleeve is improved, and bending or damage to the thermocouple sleeve during usage is avoided.

Owner:青岛聚力科创信息技术有限公司

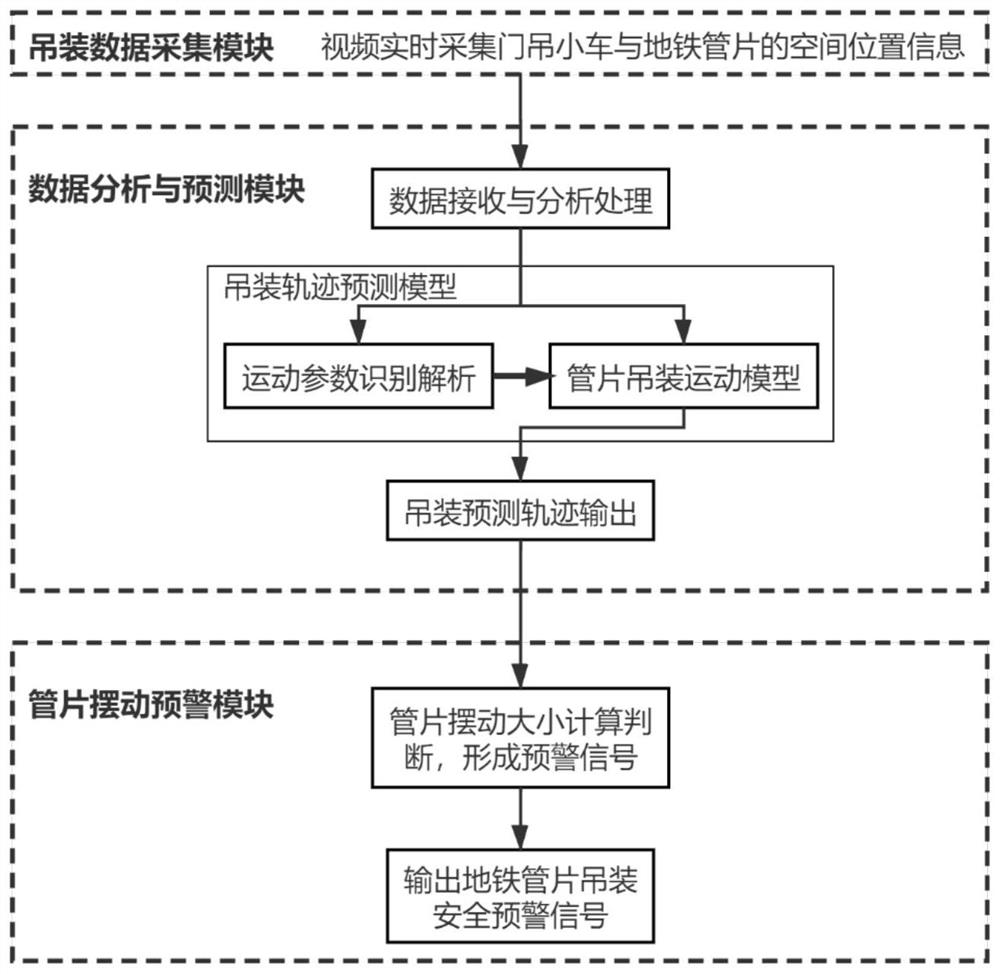

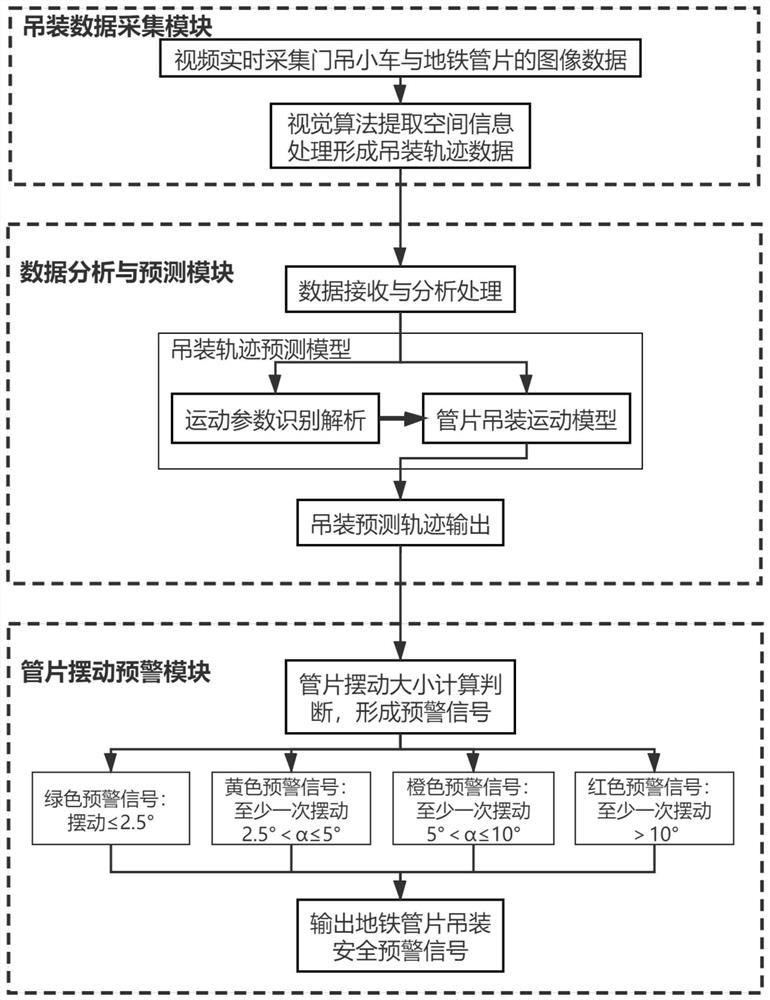

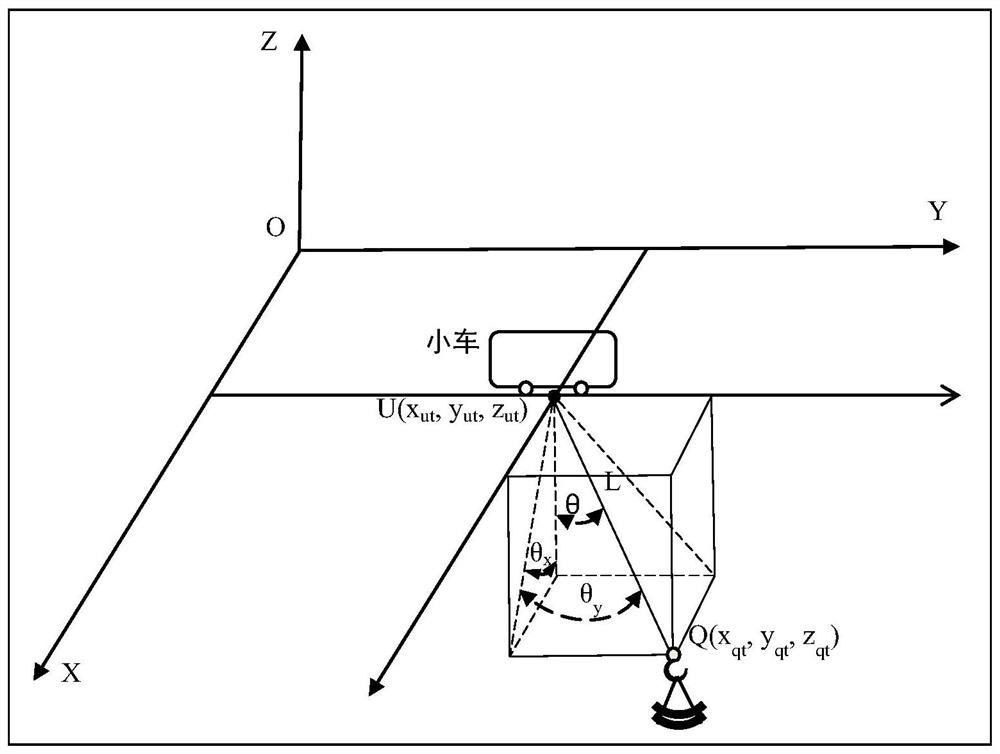

Door crane brake swing warning system and method for segment hoisting of subway shield tunnel

ActiveCN112209251BHigh data accuracyReal-time acquisition and high efficiencySafety gearData acquisitionSafety control

The invention belongs to the field of hoisting operation safety control, and discloses a door crane brake swing early warning system and method for segment hoisting of a subway shield tunnel, wherein the early warning system includes a hoisting data acquisition module, a data analysis and prediction module, and a segment swing early warning module The hoisting data acquisition module is used to collect the spatial information of the subway segment in the hoisting process in the downhole in real time; the data analysis and prediction module reasonably predicts the future hoisting trajectory of the subway segment through the above-mentioned collected data; the segment swing early warning module is based on The hoisting prediction trajectory calculates and judges the possible swing size of the subway segment and outputs the corresponding early warning signal. The invention predicts the hoisting trajectory based on the composite model of data drive and motion analysis, and uses reasonable and accurate predicted trajectory to carry out pre-warning control on the unsafe swing of the subway segment during the deceleration and braking phase of hoisting, and optimizes the safety control of the hoisting process of the subway segment , Actively avoid subway segment hoisting accidents.

Owner:HUAZHONG UNIV OF SCI & TECH

Mechanical type automatic rail gripping apparatus

InactiveCN101327889BEasy to useGuarantee the safety of hoistingLoad-engaging elementsWorking environmentEngineering

Owner:武汉凯盟机电工程有限公司

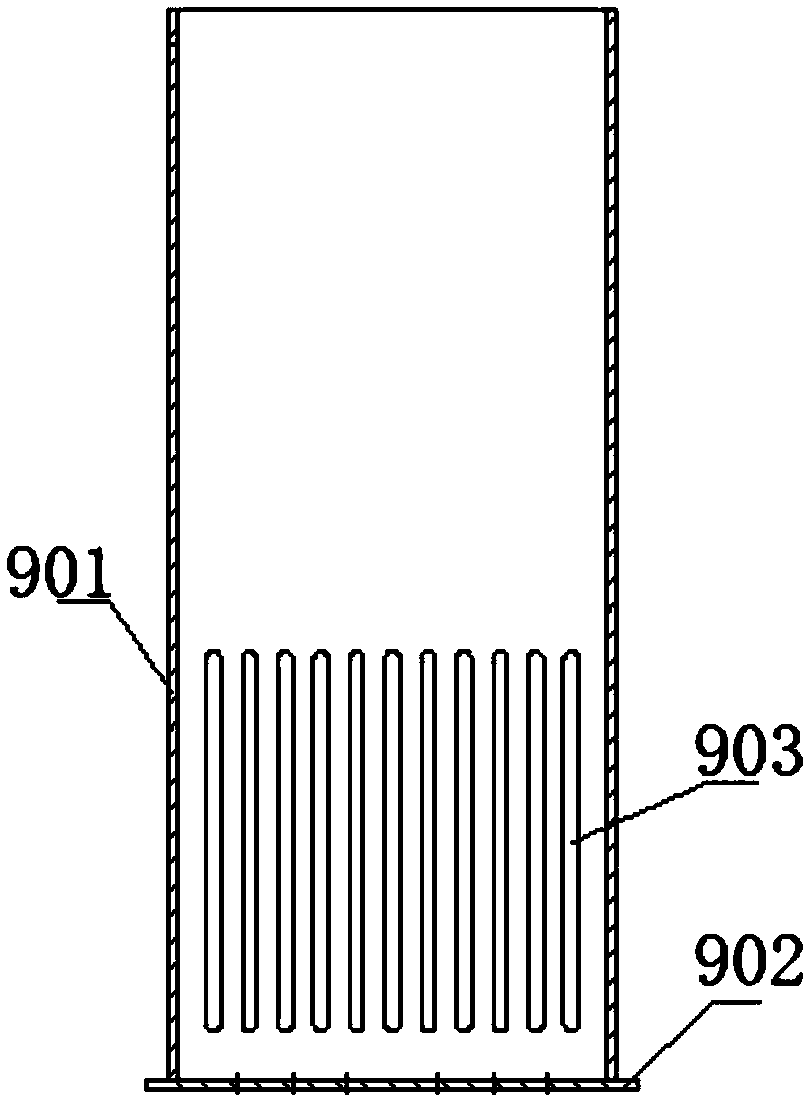

Special superstructure general assembly lifting lug structure

PendingCN112455620AWork lessReduce the amount of constructionWaterborne vesselsArchitectural engineeringUltimate tensile strength

The invention relates to a special superstructure general assembly lifting lug structure which comprises a superstructure body, bulkheads and lifting lugs, the superstructure body comprises a plurality of bulkheads, the lifting lugs are fixed to the tops of the bulkheads in a segmented mode, the superstructure body can be directly lifted through matching of the lifting lugs and steel wire ropes, and the overall lifting strength of a superstructure is guaranteed; the installation method comprises the steps that 1, on the premise that the overall hoisting strength of the superstructure is guaranteed, a lifting lug style is planned; 2, the top structure of the bulkhead is modified, and a lifting lug mounting groove is reserved and changed into a form capable of being used for lifting; 3, thelifting lugs are installed and fixed, the lifting safety is guaranteed, a lifting scheme is considered in the superstructure segmented drawing design stage, part of the bulkhead top structure is modified, the structure is directly made into a continuous lifting ring and permanently reserved, the stability and structural strength of the lifting lugs are enhanced through toggle plates, the subsequent lifting lug installation work is reduced, and the construction period is shortened. Under the condition of guaranteeing the hoisting safety, the simple steel wire rope configuration is used for hoisting, the construction amount is reduced, and the hoisting risk is reduced.

Owner:SHANGHAI ZHENHUA HEAVY IND QIDONG MARINE ENG

Three-function tower crane monitoring system

The invention discloses a three-function tower crane monitoring system which is mainly applied to tower cranes in construction engineering field. The three-function tower crane monitoring system comprises three functions including video monitoring, blind area hoisting position searching and tower body vertical perpendicularity monitoring, so that the hoisting of the tower crane is safe; the system consists of a video monitoring system, a blind area hoisting position searching system and a tower body perpendicularity monitoring system. A blind area hanging position is automatically searched by the blind area hanging position, and hoisting hooks and steel wire rope tying condition are monitored in a far distance and in a near distance by the video monitoring system, so that safe hoisting of the tower crane is ensured; during operation of the whole tower crane, the perpendicularity of the tower body of the tower crane is monitored by the tower body vertical perpendicularity monitoring system to avoid the danger of tilting of the tower crane.

Owner:JINGMEN CHUANGJIA MACHINERY TECH CO LTD

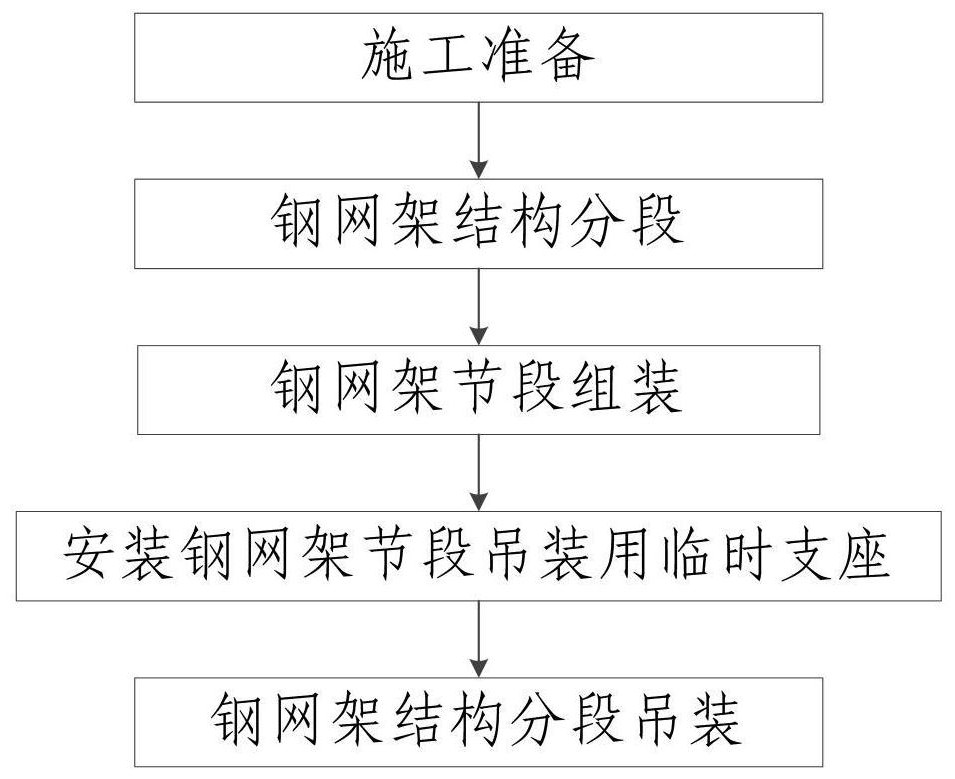

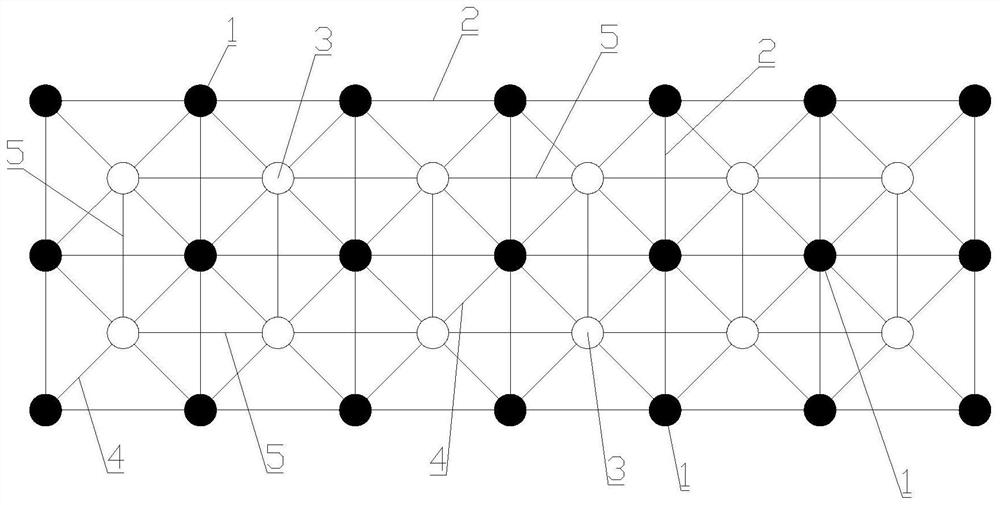

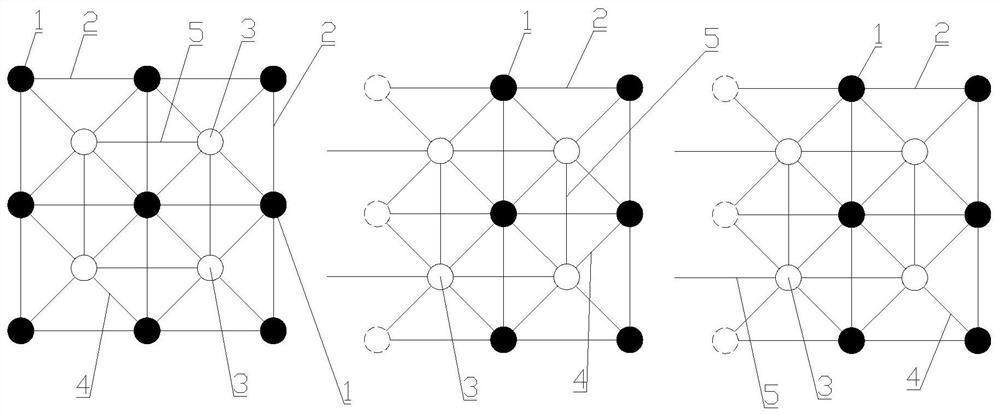

A construction method for segmental hoisting of steel grid structure

ActiveCN112267568BReduce time spent working at heightsEasy to operateBuilding material handlingArchitectural engineeringStructural engineering

The invention discloses a segmental hoisting construction method for a steel grid structure. The steel grid structure to be hoisted includes a lower grid frame and an upper grid frame, both of which are assembled by four string balls and string rods. The lower network frame and the upper network frame are connected through web bars, and the method includes the following steps: 1. Construction preparation; 2. Segmentation of the steel grid structure; 3. Assembly of steel grid segments; Temporary support for segmental hoisting; 5. Segmental hoisting of steel grid structure. The construction operation of the present invention is convenient. By dividing the steel grid structure into multiple steel grid segments, assembling the steel grid segments on the ground, and hoisting the assembled steel grid segments one by one, it can effectively Improve the assembly quality and assembly efficiency of the steel grid sections; temporary supports are used for temporary support during the hoisting of the steel grid sections, which can effectively ensure the installation accuracy of the steel grid sections and reduce the height of the steel grid structure during hoisting The working time is small and the safety risk is small.

Owner:中铁二十局集团市政工程有限公司

Tower crane video monitoring system

InactiveCN107082368AGuarantee the safety of hoistingObserve the binding in placeLoad-engaging elementsVideo monitoringSimulation

The invention discloses a tower crane video monitoring system which is mainly used for a tower crane in the field of constructional engineering. A tower crane driver can observe the dead zone situation of the ground through the tower crane video monitoring system to ensure hoisting safety. The tower crane video monitoring system is mainly composed of a camera A, two cameras B, a bracket A, a bracket B, a wireless signal receiver, a coiling wheel, a signal output line A, a signal output line B, a signal output line C and a signal line fixing rack. The main working principle of the tower crane video monitoring system is as follows: when a translation trolley is moved below a lifted object, the tower crane driver can remotely observe the ground situation through a video signal transmitted by the camera A; when a lifting hook descends to the lifted object, the tower crane driver can observe the surrounding situation of the lifted object at short range through the video signals transmitted by the two cameras B; and the tower crane driver adjusts the viewing angles of the two cameras in a controlling room to observe the lifting hook and the binding in-position situation of a steel wire rope.

Owner:JINGMEN CHUANGJIA MACHINERY TECH CO LTD

F-shaped standard frame for assembly and disassembly of prefabricated beam formwork and construction method

InactiveCN110306792AExtended service lifeIncrease frequencyForms/shuttering/falseworksGantry craneSafety risk

The invention discloses an F-shaped standard frame for assembly and disassembly of a prefabricated beam formwork and a construction method and belongs to the technical field of efficient assembly anddisassembly of prefabricated beam formworks. According to the construction method, the F-shaped standard frame is welded and assembled with I-steel, and the F-shaped standard frame cooperates with a beam plant gantry crane to transfer the formwork, and the method can rapidly and effectively improve the formwork disassembly and assembly efficiency; besides, action force is exerted on a cross rib inthe formwork, and therefore the safety risk caused by a long load distance, rotation and the like in the formwork transferring process can be lowered. Firstly, the machined standard frame is conveyedto below a formwork needing disassembly (assembly) through the gantry crane; then, workers cooperate with the gantry crane to clamp the standard frame at the cross rib on the outer side of the formwork and detect whether the standard frame is firm or not, the gantry crane is adopted to convey the formwork to an operation platform, and the operations are sequentially and circularly conducted untilthe task is completed. The F-shaped standard frame for assembly and disassembly of the prefabricated beam formwork achieves the effects of lowering safety risk, reducing damage to the formwork, improving construction efficiency, accelerating construction progress and then lowering construction cost.

Owner:CHINA MCC17 GRP

A single-side glass reinforcement-reinforcement cage structure for the ground connection wall of the shield tunnel

ActiveCN110080296BMeet the bending capacityMeet the force requirementsArtificial islandsUnderwater structuresGlass fiberShield tunneling

The invention discloses a unilateral glass rib-reinforcement cage structure for a shield tunnel portal diaphragm wall. The structure comprises an underground diaphragm wall reinforcement cage, a tunnel portal steel ring is tightly attached to and connected to the soil backing side face of the underground diaphragm wall reinforcement cage, an annular reinforcement truss which is concentric with thetunnel portal steel ring is connected between a soil facing side face and a soil backing side face of the underground diaphragm wall reinforcement cage, the annular reinforcement truss is located onthe periphery of the tunnel portal steel ring, the parts, located on the inner periphery of the tunnel portal steel ring, of soil facing side vertical reinforcements striding over the tunnel portal steel ring are replaced by vertical glass fiber bars, and the parts, located on the inner periphery of the tunnel portal steel ring, of soil facing side horizontal reinforcements striding over the tunnel portal steel ring are replaced by horizontal glass fiber bars. The tunnel portal steel ring is used for receiving and pre-burying a shield tunneling machine when serving as a main body structure, and the arranged annular reinforcement truss is used for ensuring that the glass fiber bars are not influenced by gravity to be infinitely broken when the reinforcement cage is lifted, so that the lifting safety of the reinforcement cage can be ensured, and the stress requirement of a wall body can be met.

Owner:CHINA TIESIJU CIVIL ENG GRP CO LTD

Rapid installation closure construction method for steel beam bolting closure section splice plate

ActiveCN112663498AReduce construction difficultyGuarantee the safety of hoistingBridge erection/assemblyPhotovoltaic energy generationStructural engineering

The invention discloses a rapid installation closure construction method for a steel beam bolting closure section splice plate. A hinge device is positioned firstly, and then the splice plate is installed on a closure section beam body through the hinge device so that the needed splice plate is temporarily fixed in the end surface of the closure section beam body before the closure section beam body is hoisted, and the hoisting safety is effectively guaranteed; hoisting operation is convenient, during closure, temporary fixation is removed firstly, then the splice plate is directly rotated to the position, to be connected, outside the end surface of the closure section beam body to the closure section beam body and the installed beam section, then the splice plate is fixed through bolts, closure of the installed beam section and the closure section beam body is completed, and repositioning during closure is not needed; and the splicing plate does not need to be hoisted outside the closure section beam body, the construction difficulty of splice plate construction of the closure section beam body and the installed beam section at a high altitude can be reduced, the efficiency can be improved in the construction process of splice plate construction of the closure section beam body and the installed beam section, the construction period is shortened, and the construction safety risk is reduced.

Owner:CHINA RAILWAY NO 2 ENG GRP CO LTD +1

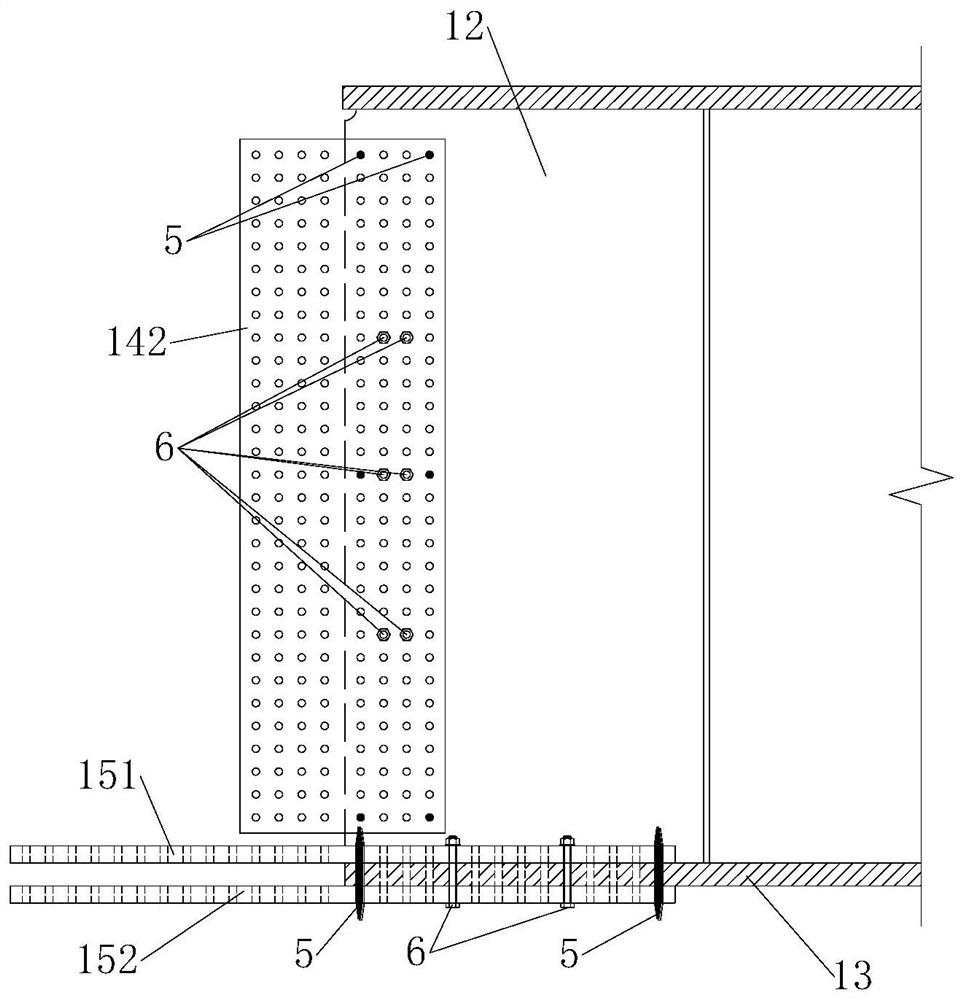

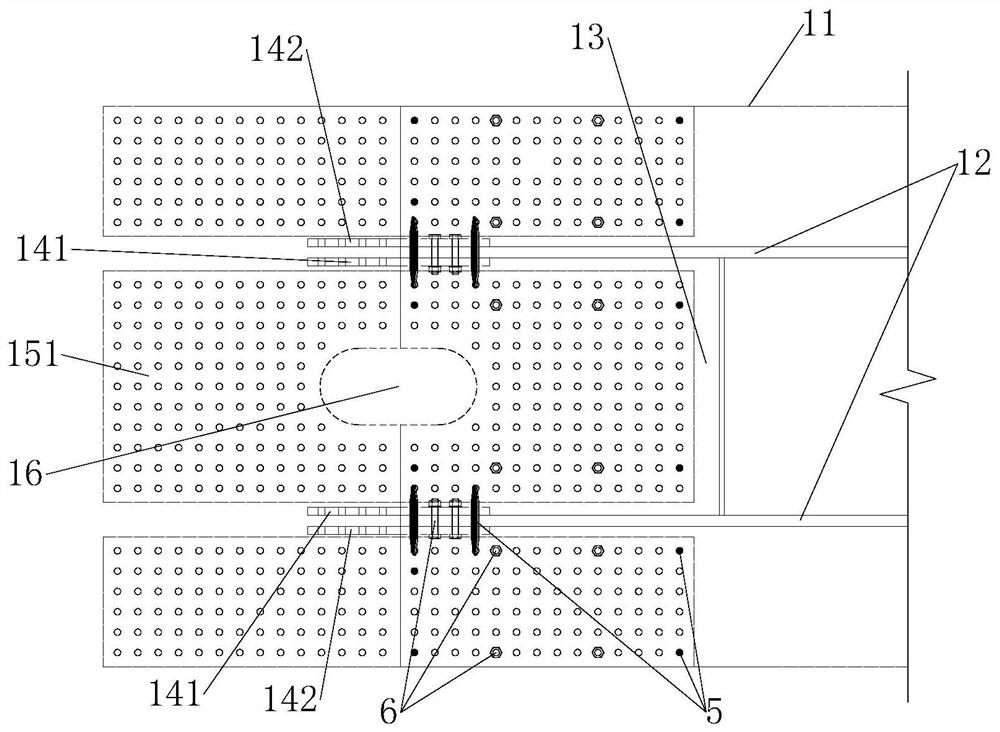

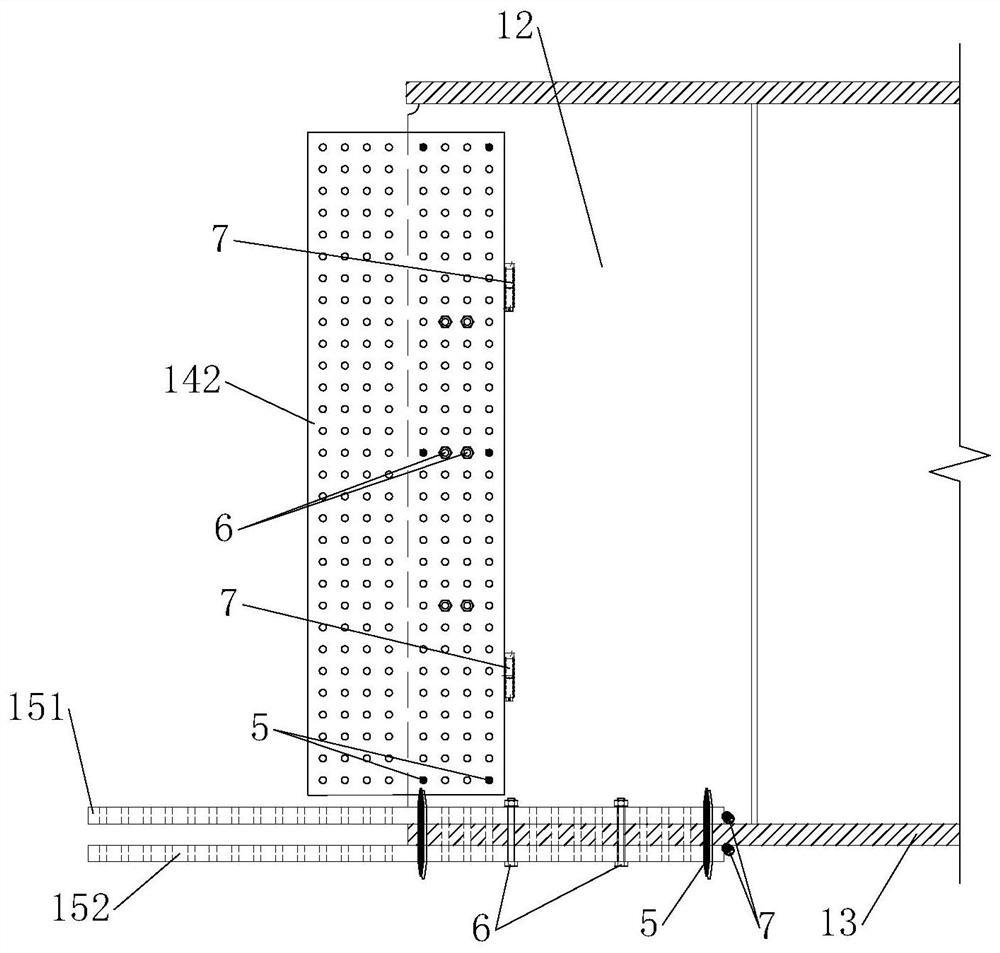

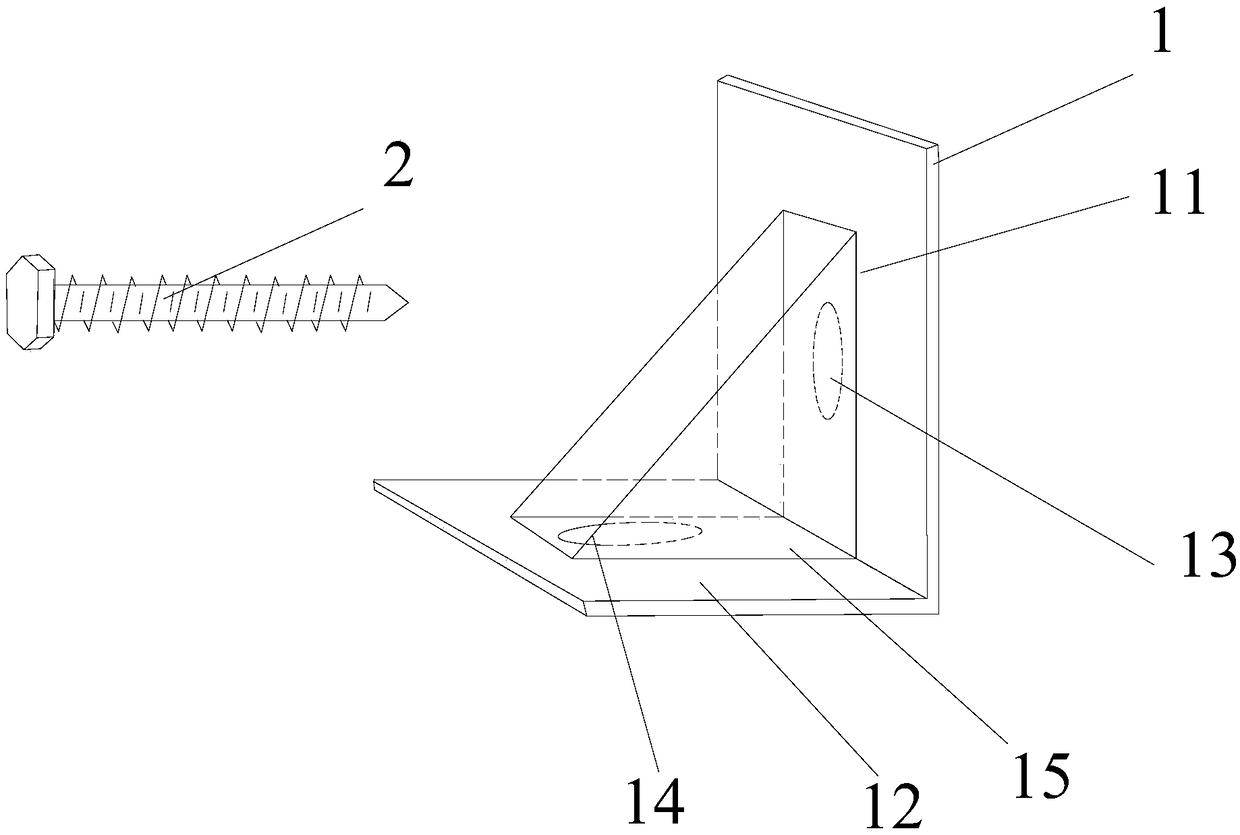

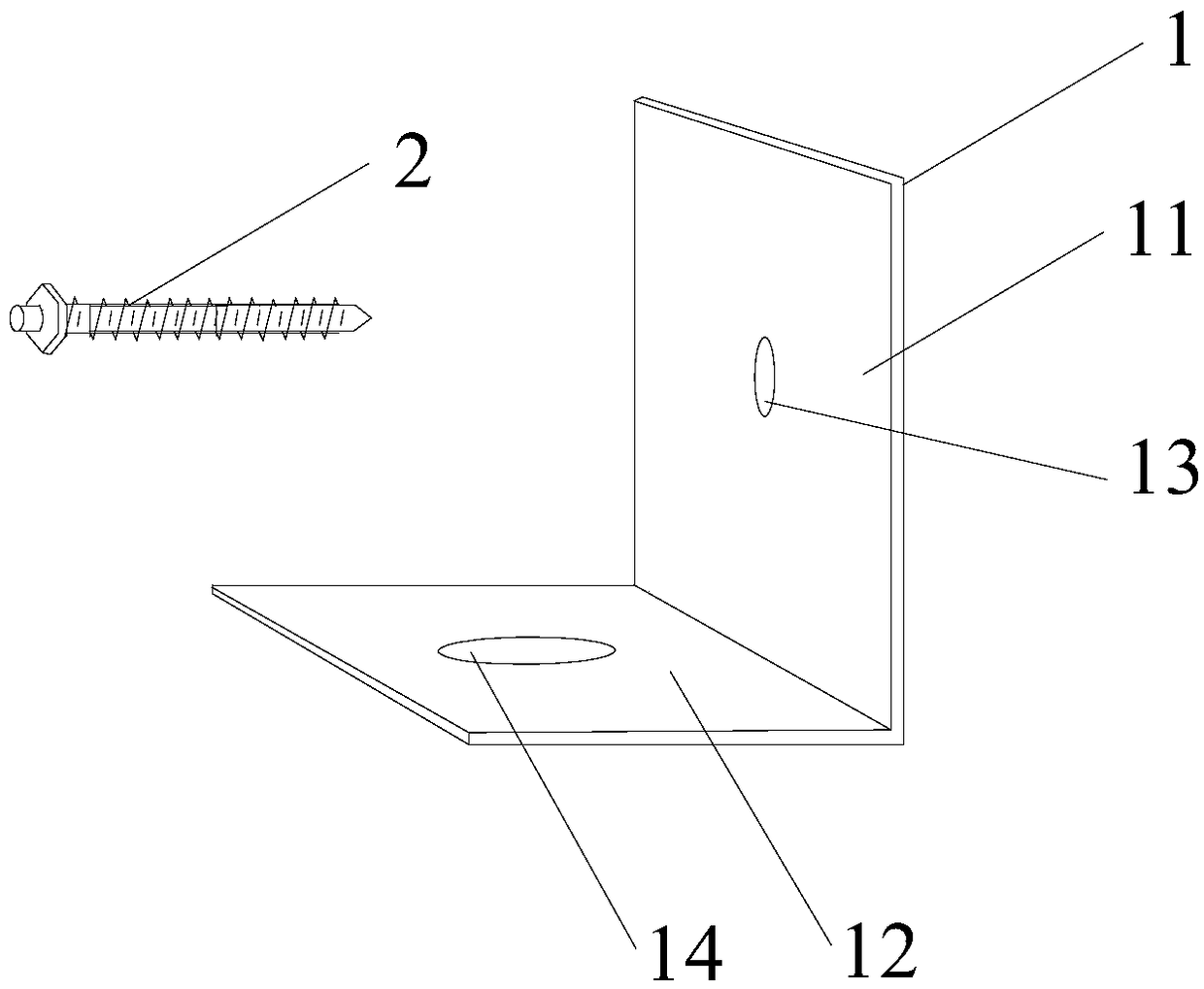

Tool for fabricated concrete wall lifting adjustment, fabricated wall and construction method

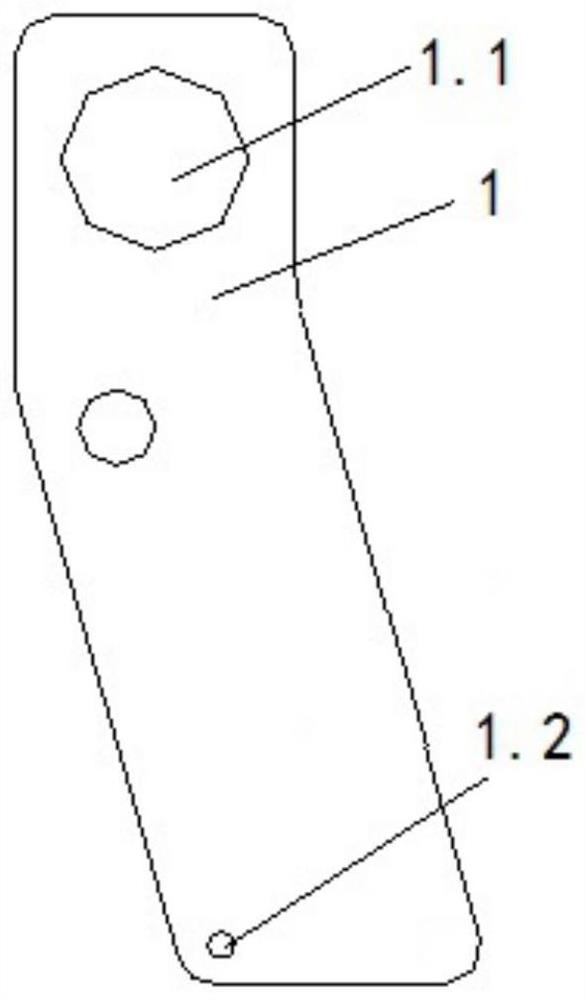

PendingCN109138442AGuarantee the safety of hoistingEasy to adjust the wall positionWallsBuilding material handlingEngineeringStructural engineering

The invention discloses a tool for fabricated concrete wall lifting adjustment, a fabricated wall and a construction method. The tool for the fabricated concrete wall lifting adjustment comprises a structural member and a bolt. The structural member comprises a first base plate and a second base plate connected with the first base plate. A through hole is formed in the first base plate, and a crowbar insertion hole is formed in the second base plate. The through hole is used for enabling the bolt to pass through, and the bolt is used for fixedly connecting the structural member to a prefabricated part. The tool, the fabricated wall and the construction method can reduce the damage to a concrete wall surface and a corner protection layer in the prizing process of the crowbar (that is, avoidthe direct contact between the crowbar and a wall body so as not to damage the wall body and destroy the integrity of the part), ensure the attractiveness, and ensure the quality of the part.

Owner:SANY CONSTR TECH CO LTD

Multifunctional connecting device suitable for railway wagon hoisting

PendingCN114772435AGuarantee the safety of hoistingEasy to operateLoad-engaging elementsTruckClassical mechanics

The multifunctional connecting device comprises a lower jaw plate, an upper pressing plate and a rotating shaft, a through hole is formed in one end of the lower jaw plate, the other end of the lower jaw plate inclines upwards, the upper pressing plate comprises a hook part and a connecting part, the hook part is arranged at the upper end of the connecting part, and the lower end of the connecting part is rotationally connected with the middle of the lower jaw plate; the multifunctional connecting device comprises a through hole, a rotating shaft and a hanging ring, the rotating shaft is rotationally connected into the through hole, the two ends of the rotating shaft are exposed out of the two sides of the through hole, the hanging ring is in a U shape, and the two ends of the hanging ring are detachably connected with the two ends of the rotating shaft. Small-size deviation of the gravity center is automatically repaired through rotation of the hook and the rotating shaft, hoisting safety is guaranteed, the device is suitable for being used for connection of various traction beams and bogies, the device can be integrally removed by loosening the hanging ring and the axle during dismantling, operation is easy, and the device can be used for next time.

Owner:CRRC TAIYUAN CO LTD

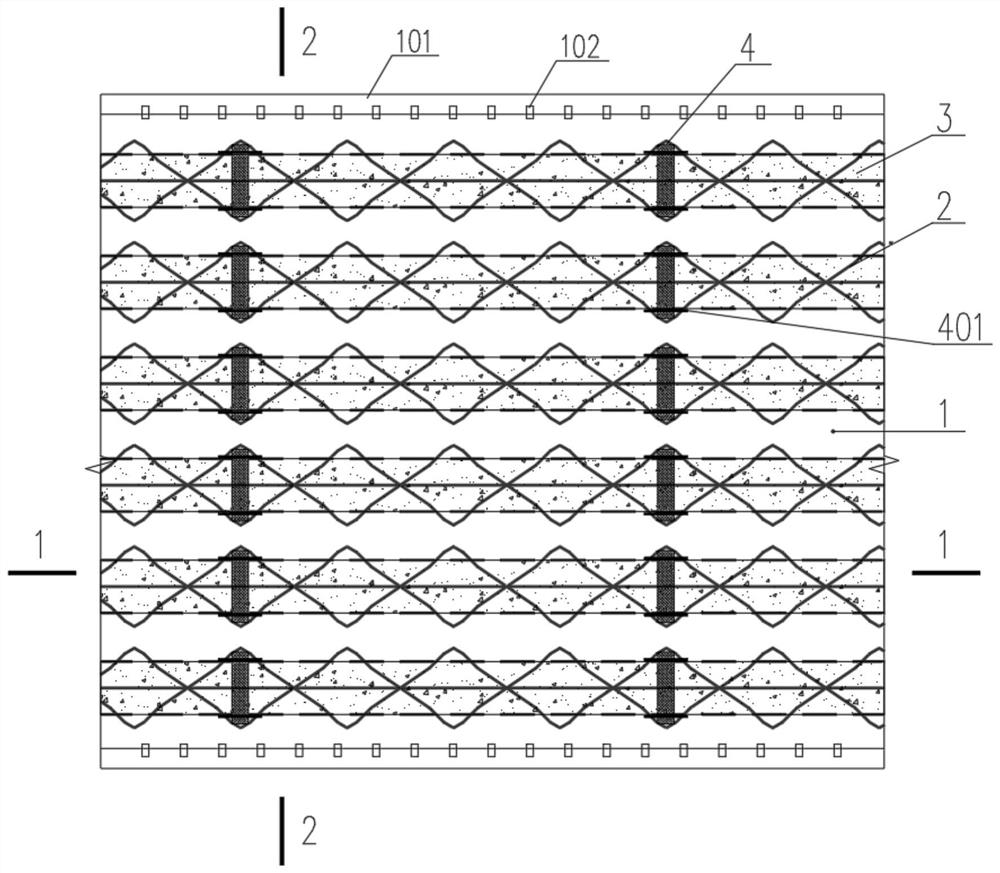

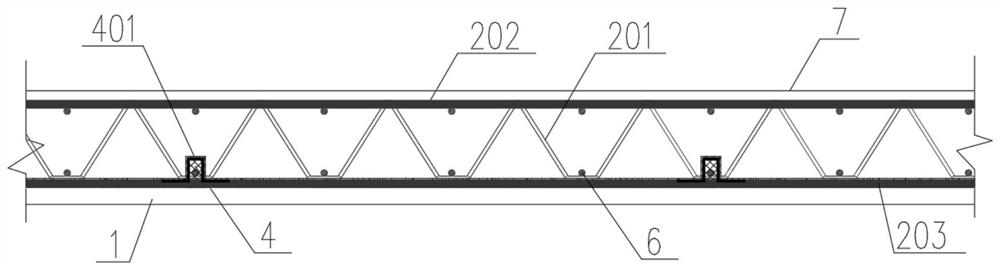

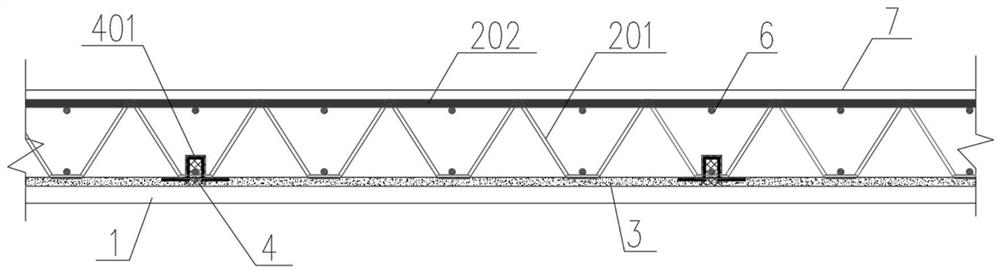

Uhpc-based prefabricated formwork-removal-free steel bar truss floor support plate and use method

ActiveCN113123506AGood material durabilityReduce dosageFloorsCeramic shaping apparatusFloor slabResidence

The invention relates to an uhpc-based prefabricated formwork-removal-free steel bar truss floor support plate. The floor support plate is composed of uhpc bottom formworks, steel bar trusses, steel bar truss uhpc bonding belts and steel bar truss uhpc anchoring blocks, the uhpc bottom formworks are formed by pouring uhpc, and bottom formwork connecting structures are formed on the edges of the uhpc bottom formworks and used for connecting the two adjacent uhpc bottom formworks; and the steel bar trusses are arranged on the uhpc bottom formworks and connected with the uhpc bottom formworks through the steel bar truss uhpc bonding belts and the steel bar truss uhpc anchoring blocks to form a whole. According to the formwork-removal-free steel bar truss floor support plate, the material durability is good, the using amount is low, and the structural stress performance and the anti-seismic performance of a fabricated floor slab are achieved with low engineering cost. The floor support plate is low in resource and energy consumption, environment-friendly in industrialized production, high in construction speed, simple in connection, convenient and fast to construct, light in component weight and convenient to transport, hoist and mount, can be widely applied to low multi-story, high-rise and super high-rise buildings of various residences, offices, hotels, business and the like, and is a high-quality fabricated floor slab.

Owner:重庆涛扬绿建科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com