Mechanical type automatic rail gripping apparatus

A mechanical and automatic technology, applied in the field of spreaders, can solve the problems of inconvenient operation, inconvenient operation, high cost, etc., and achieve the effects of high economy and practicability, simple, lightweight and reliable structure, and a wide range of applications.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Below in conjunction with accompanying drawing, the present invention is described in further detail:

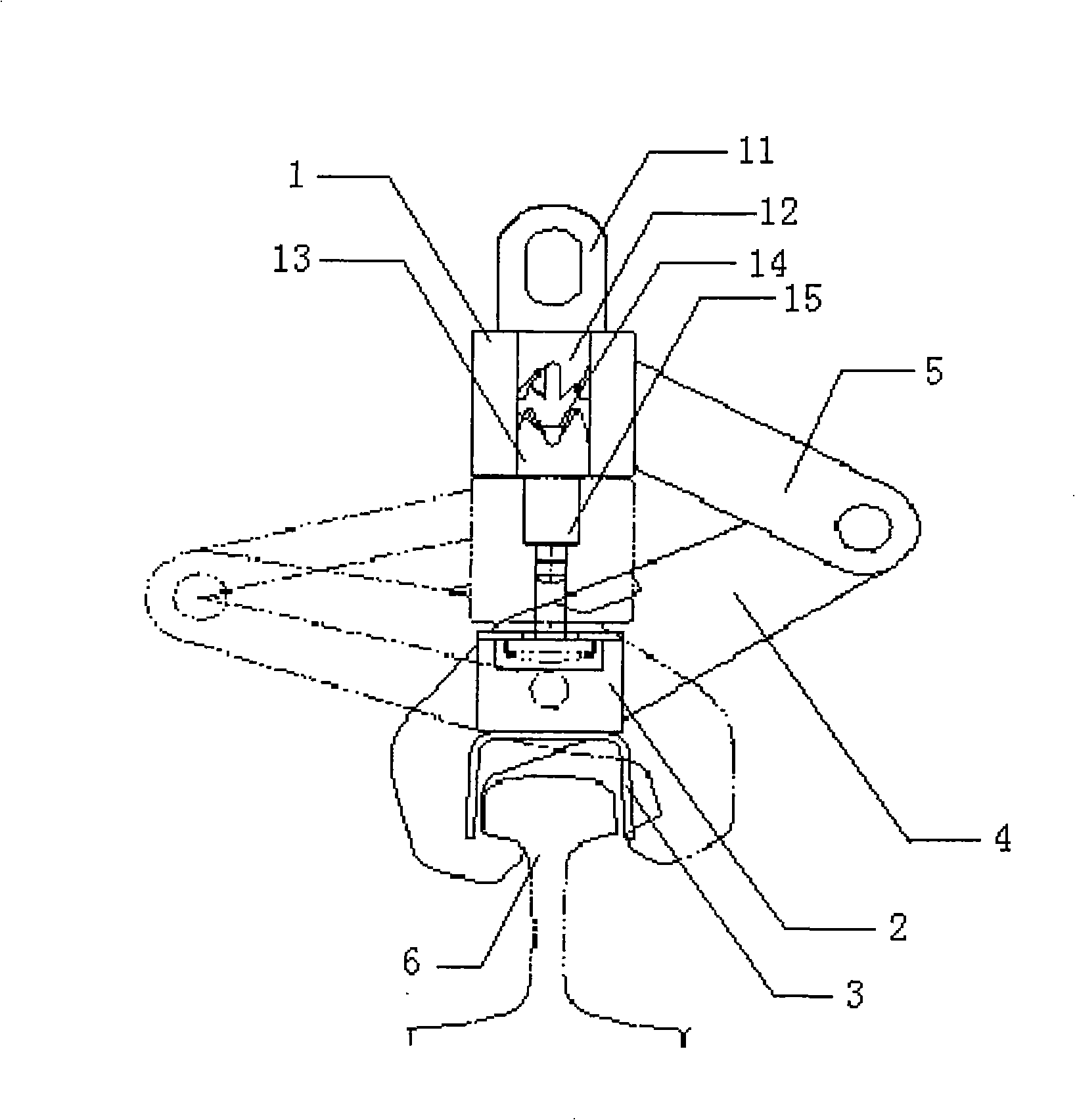

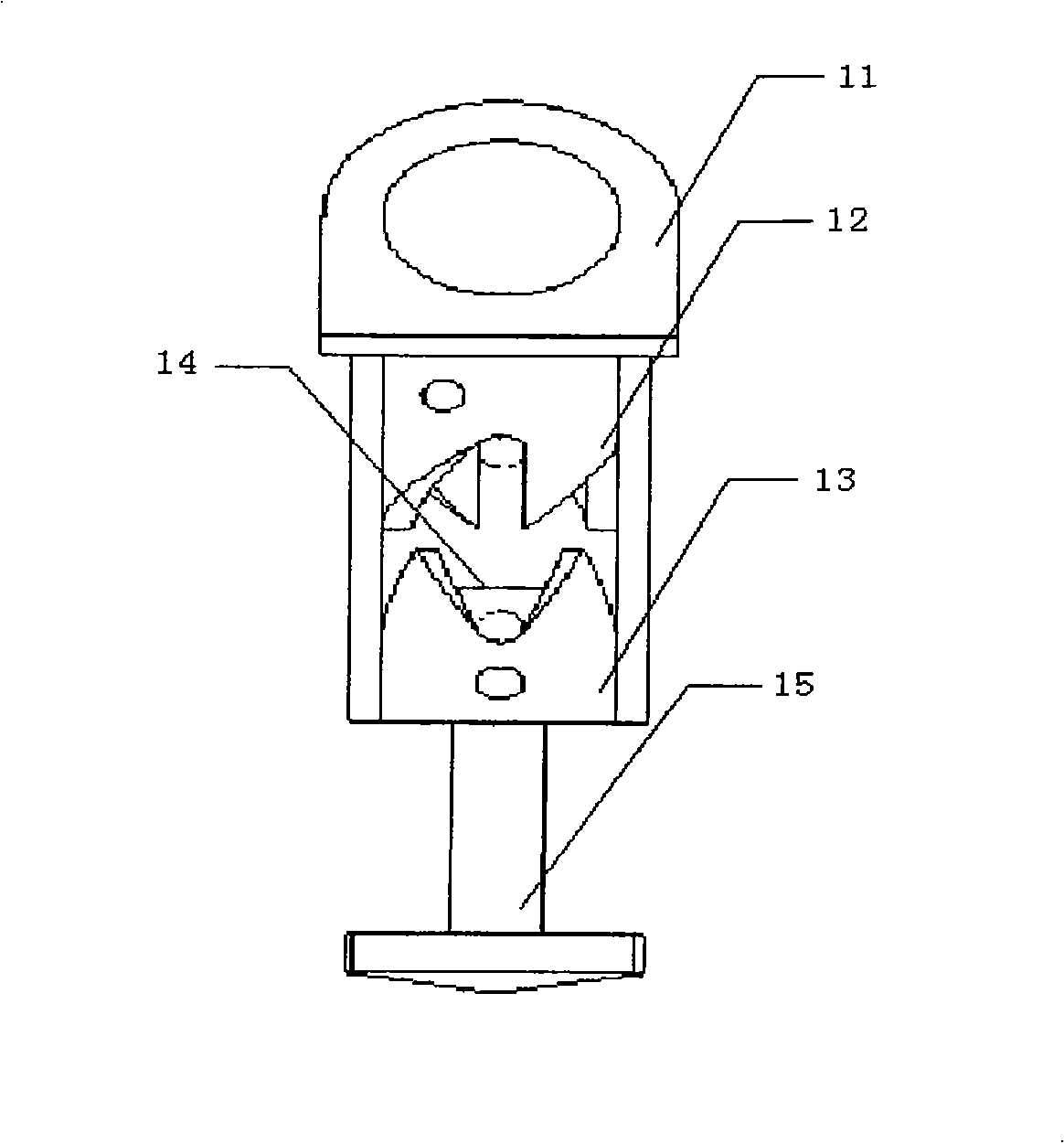

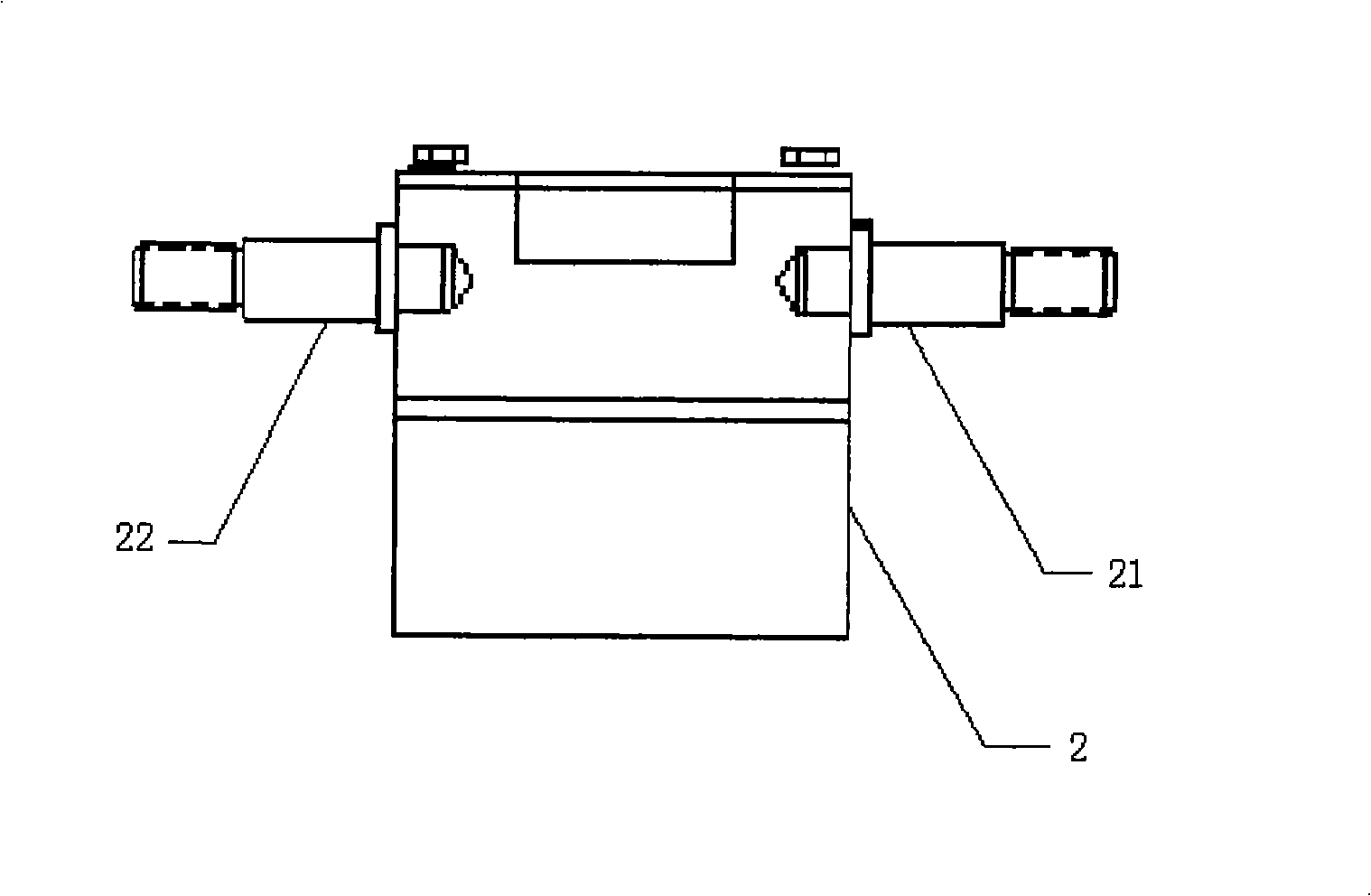

[0022] The device is composed of a hook base 1, a suspension base 2, a guide plate 3, a clamp arm 4, and a connecting rod 5. The hook base 1 is composed of a lug plate 11, an upper gear ring 12, a lower gear gear 13, a screw rod 14, and a T-shaped hook 15. , A first shaft 21 and a second shaft 22 are arranged on the suspension base 2 . The clamp arm 4 is connected with the suspension base 2 through the first shaft 21 and the second shaft 22 on the suspension base 2. The clamp arm is used to grasp and clamp the rail 6. One end of the connecting rod 5 is connected with the hook base 1 through the shaft, and the other end The shaft is connected to the clamp arm 4, and the connecting rod 5 is connected to the clamp arm 4 to form a four-link structure. The four-link displacement is driven by the up and down movement of the hook base 1, so that the clamp arm 4 only needs to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com