Reinforcing device and method for overweight reinforcement cage of ultra-deep underground diaphragm wall

A technology for underground diaphragm walls and reinforcement devices, which is applied in sheet pile walls, buildings, and infrastructure engineering, etc. It can solve problems such as quality and safety accidents, deformation and de-soldering, and large spot welding forces, so as to ensure overall rigidity and hoisting safety , prevent loosening or even falling off, and enhance the effect of tensile capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

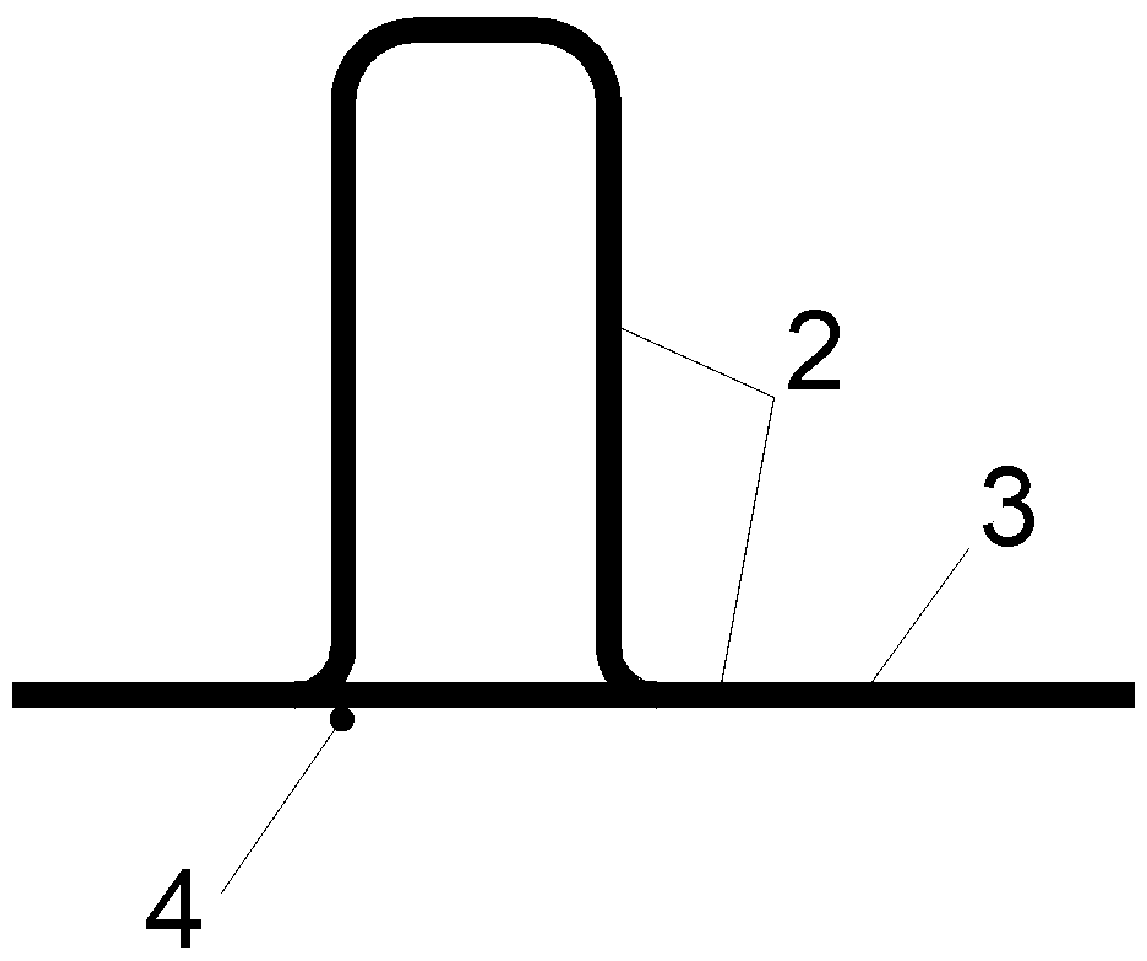

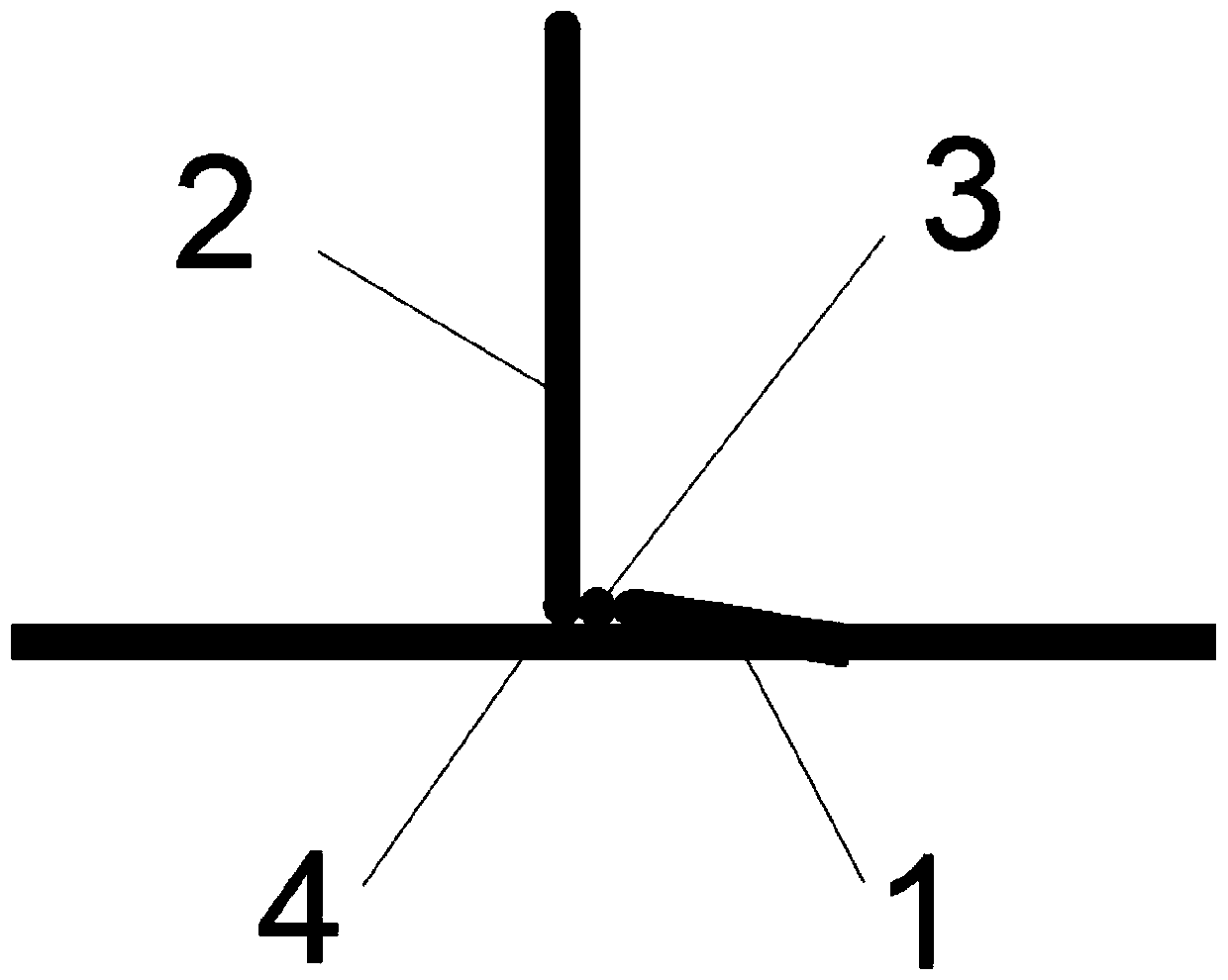

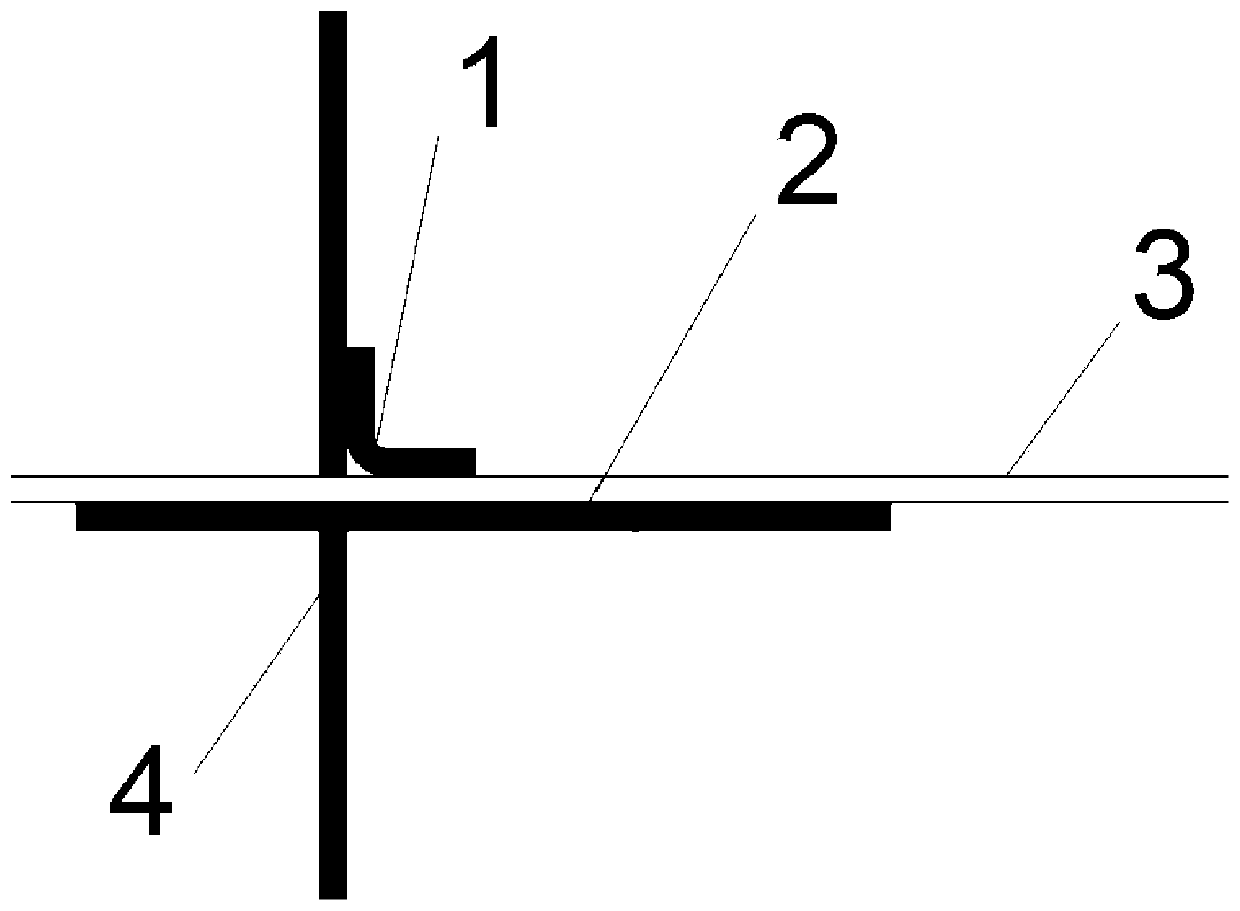

[0021] Such as Figure 1 to Figure 4 As shown, a super-heavy steel cage reinforcement device for an ultra-deep underground diaphragm wall includes a super-heavy steel cage, an L-shaped round bar 1, a U-shaped bar 2 at a lifting point, a main longitudinal bar 3 at a hanging point, and a horizontal truss bar 4 at a hanging point on the super-heavy steel bar cage. One end of the L-shaped round bar 1 is fully welded with the U-shaped bar 2 of the lifting point and the longitudinal main bar 3, and the other end is fully welded with the horizontal truss bar 4 of the lifting point at this position. The point U-shaped reinforcement is transferred to the longitudinal main reinforcement and the longitudinal truss reinforcement, and then to the horizontal truss reinforcement.

[0022] 10cm full welding is used between the left and right four sealing bars of the h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com