Non-anchor-rod type multifunctional embedded box iron and anchoring and installing method

An installation method and pre-embedded groove technology, which are applied in the direction of construction and building structure, can solve the problems of inconsistent deformation, instability, uneven stress and deformation of the groove opening, and achieve the purpose of increasing the longitudinal shear bearing capacity, The tensile bearing capacity is improved, and the effect of installation and application is enhanced

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

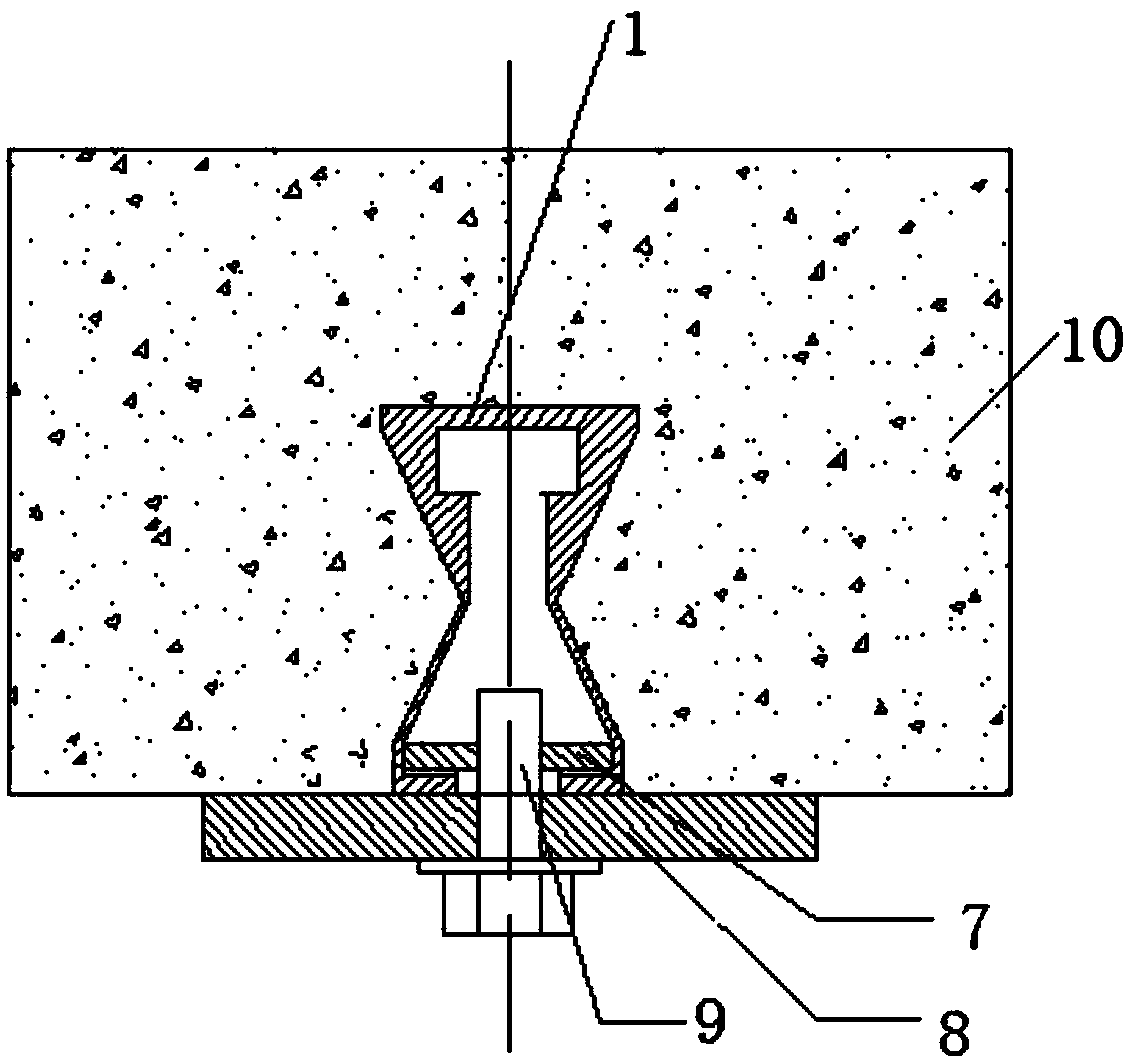

[0041] Example 1 (When the design tensile and shear load bearing capacity is small)

[0042] The installation diagram of the anchor installation method of this embodiment is shown in figure 1 , The anchoring device used in the anchoring installation method includes embedded channel steel 1, single-head bolt 9, installation assembly 8 and toothed wing nut 7, such as Picture 10 As shown, the pre-buried channel steel 1 includes a trough body and a main chute 101 provided on the trough body. Both sides of the trough body are provided with a waist structure. The pre-buried channel steel 1 passes through the waist structure and the concrete 10 The main chute 101 is recessed in the notch, and the force-bearing portion 104 is formed at the notches on both sides of the main chute 101. The inner side of the force-bearing portion 104 is provided with anti-slip teeth 105, The top of the main chute 101 is provided with a T-shaped chute 2, and the T-shaped chute 2 is integrated with the groove...

Embodiment 2

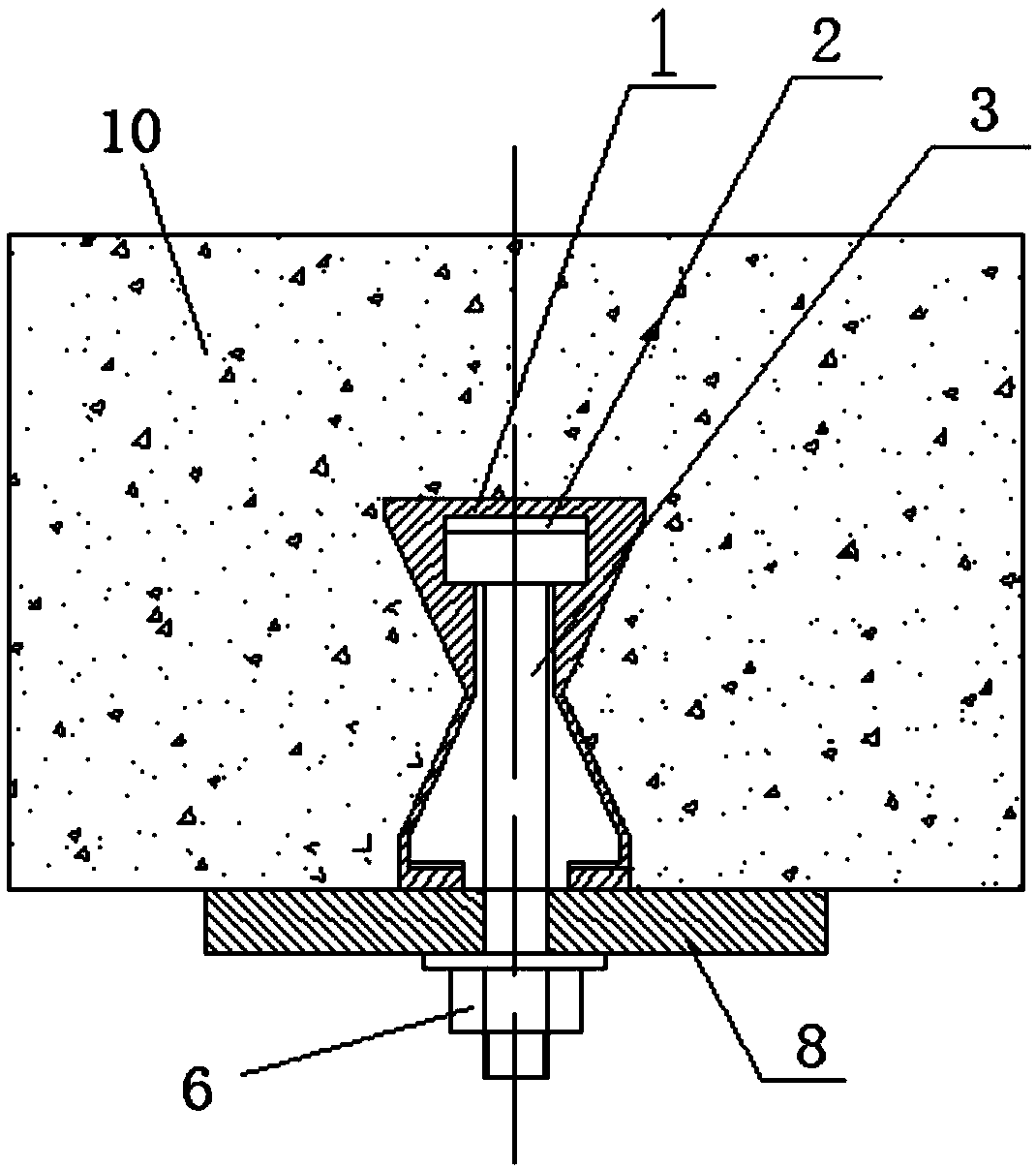

[0044] Example 2 (When the design tensile bearing capacity is large, there is no requirement for the shear bearing capacity)

[0045] The installation diagram of the anchor installation method of this embodiment is shown in figure 2 The anchoring device used in the anchoring installation method includes embedded channel steel 1, T-bolt 3, mounting assembly 8 and fastening nut 6. The embedded channel steel 1 in this embodiment is the same as that in embodiment 1, using T-shaped chute 2. Integrated with the tank body.

[0046] The embedded channel steel 1 is embedded and anchored and installed in the concrete 10. When fixing the installation component 8, first install the T-bolt 3 in the T-shaped chute 2, move it to the position to be installed, and then install the component 8 is sleeved on the threaded end of the T-bolt 3, and a nut 6 is tightened on the threaded end of the T-bolt 3, and the mounting assembly 8 is fixed by the tightening nut 6.

Embodiment 3

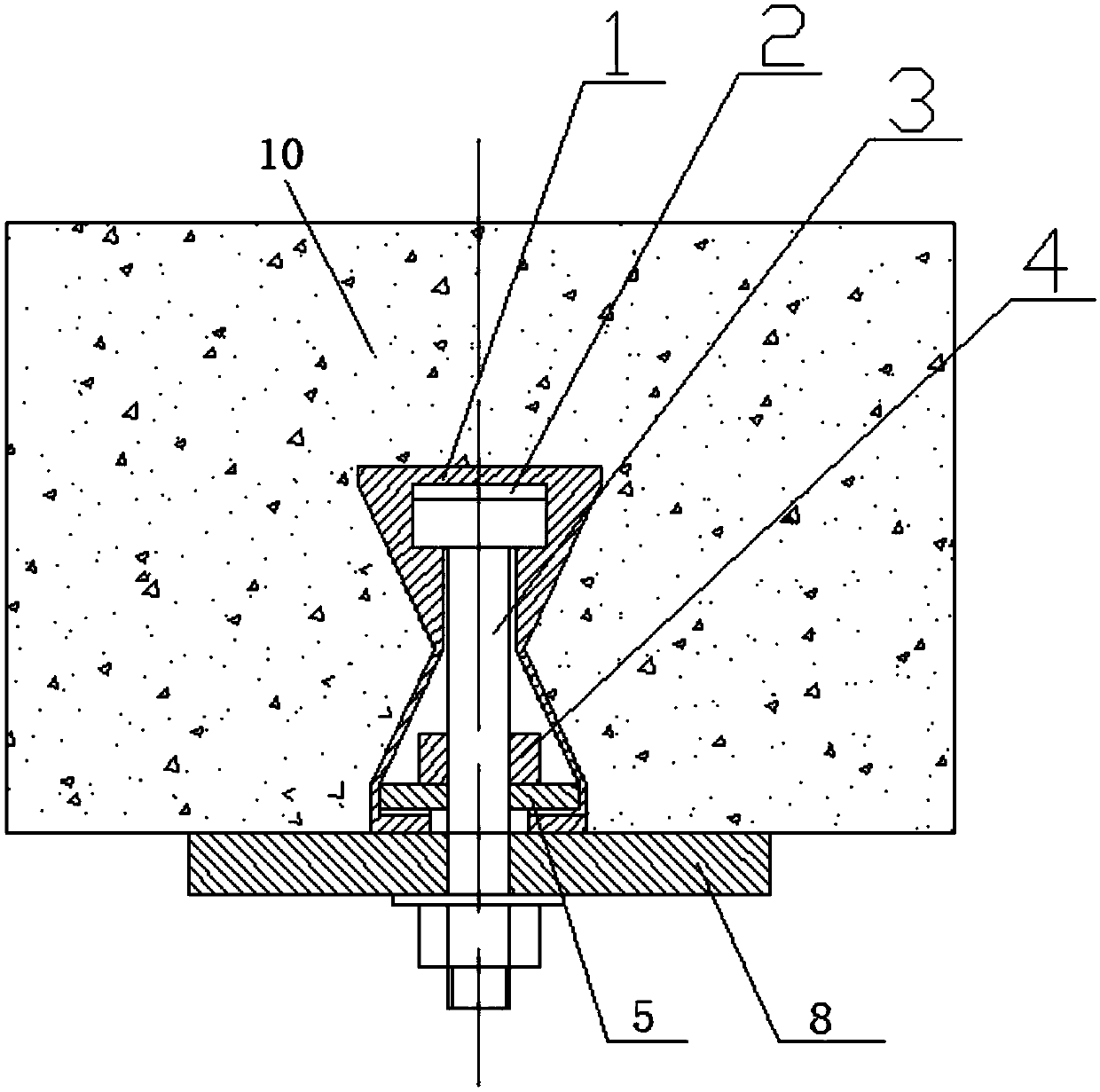

[0047] Example 3 (when the design tensile and shear bearing capacity are large)

[0048] The installation diagram of the anchoring installation method of this embodiment is shown in image 3 The anchoring device used in the anchoring installation method includes embedded channel steel 1, T-bolt 3, mounting assembly 8, fastening nut 6, fixing nut 4, and toothed butterfly pad 5. In this embodiment, the embedded channel steel 1 and As in Embodiment 1, the T-shaped chute 2 is integrated with the groove body.

[0049] The embedded channel steel 1 is embedded and anchored and installed in the concrete 10. When fixing the installation assembly 8, before the T-bolt 3 is installed in the T-shaped chute 2, the fixing nut 4 and the fixing nut 4 and Toothed butterfly block 5, then install the T-bolt 3 in the T-shaped chute 2, move to the position where it needs to be installed, and then tighten the fixing nut 4 to press the toothed butterfly block 5 on the bearing part 104 To fix the T-bolt 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com