Grouting structure and grouting method for enhancing pulling resistance of pile foundation after self-balance detection

A self-balancing and post-testing technology, applied in infrastructure engineering, construction, etc., can solve the problems of low structural strength and low tensile strength of engineering piles, improve engineering application efficiency and application value, and enhance tensile bearing capacity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

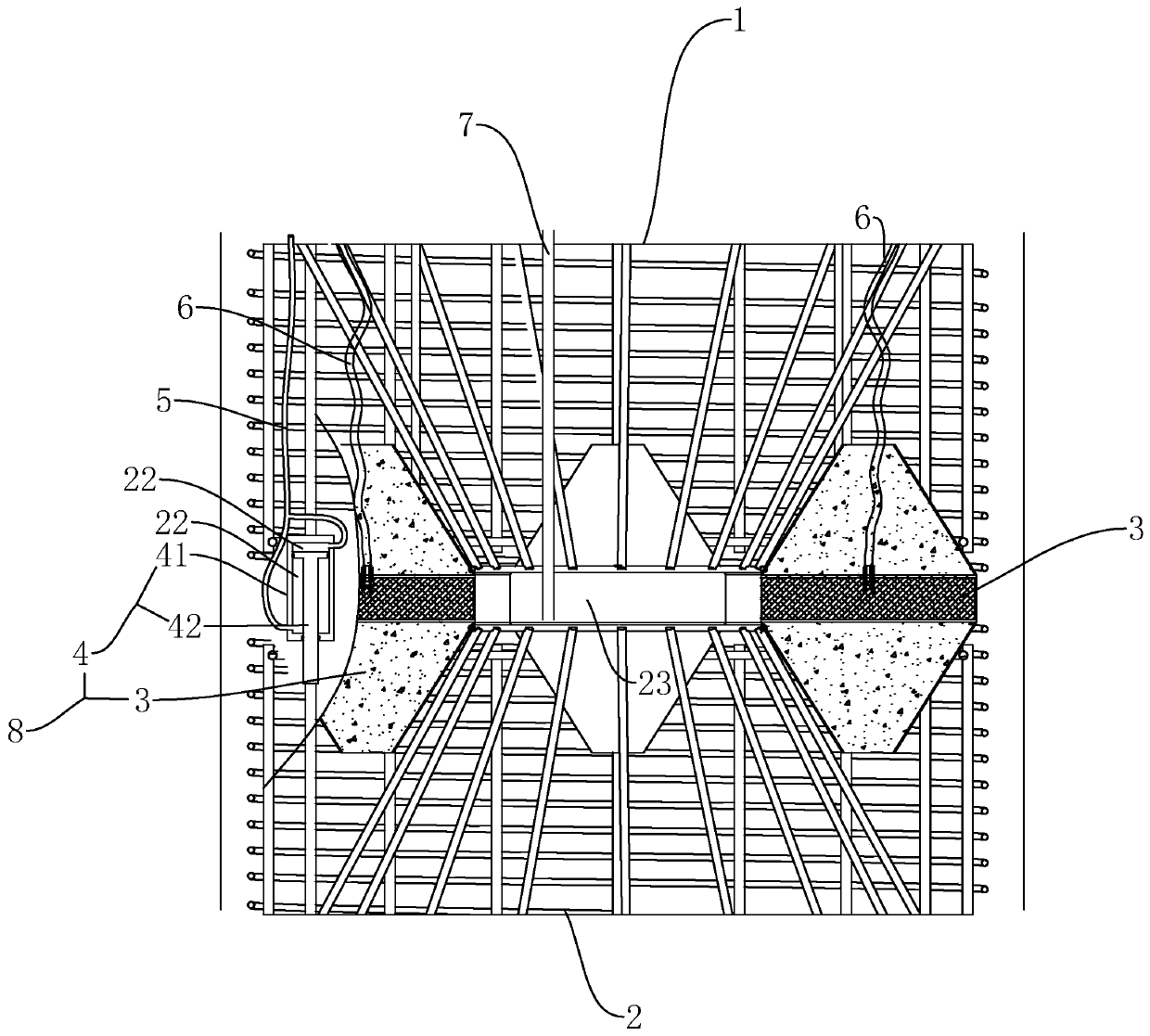

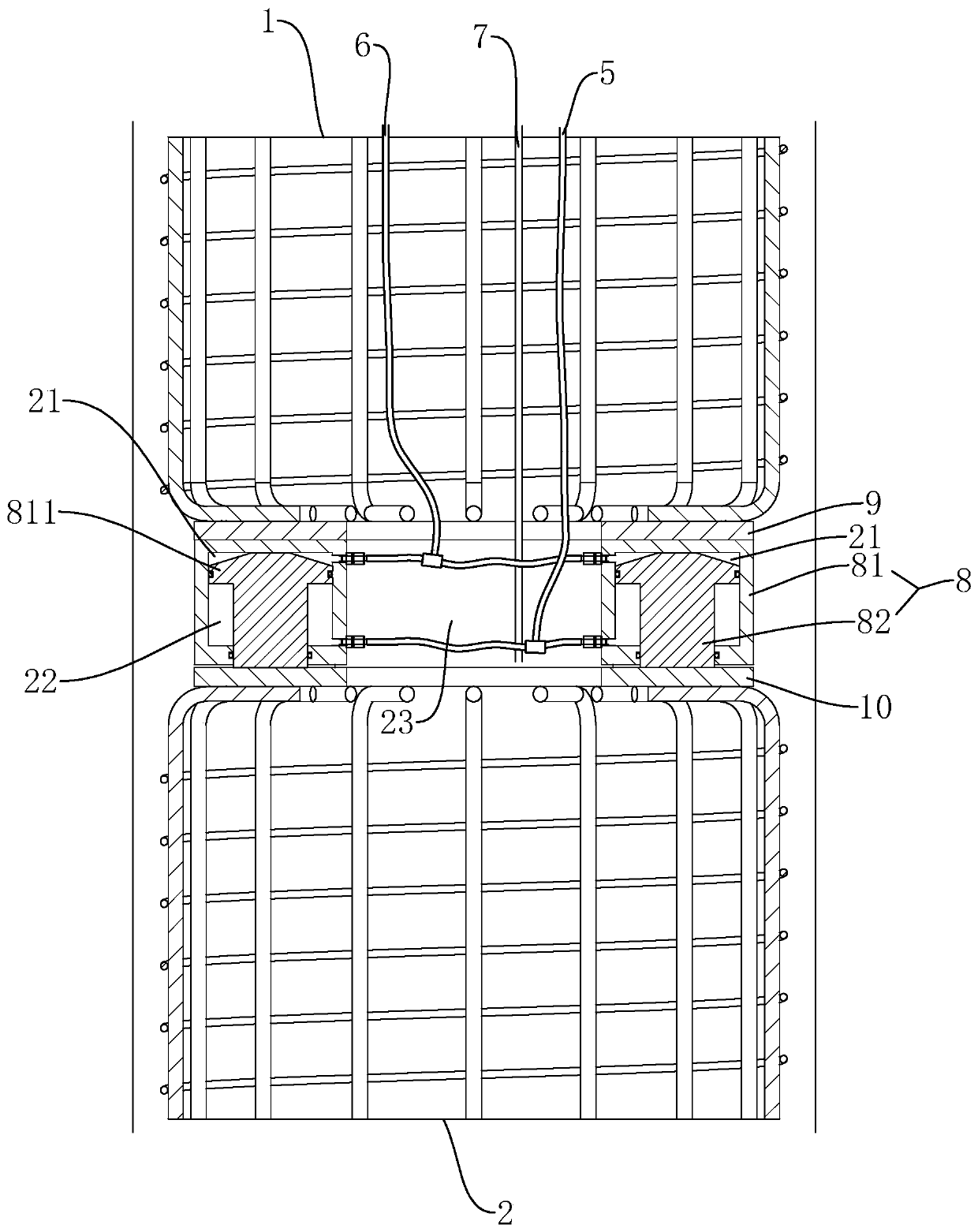

[0023] combine Figure 1 to Figure 2 The grouting structure for enhancing the pullout resistance of the pile foundation after the self-balancing test of the present invention is further described.

[0024] A grouting structure for enhancing the pullout resistance of a pile foundation after a self-balancing test, including an upper reinforcement cage 1 and a lower reinforcement cage 2, and is characterized in that: it also includes a load-loading structure arranged between the upper reinforcement cage 1 and the lower reinforcement cage 2 and guide device 8;

[0025] The loading and guiding device 8 has a loading cavity 21 and a guiding cavity 22 inside, and the loading cavity 21 and the guiding cavity 22 are respectively connected with a loading cavity grouting pipe 6 and a guiding cavity grouting tube 5;

[0026] The outer cavity 23 formed between the outside of the loading and guiding device 8, the upper steel cage 1 and the lower steel cage 2 is connected with an external g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com