Method of reinforcing low-strength concrete beams and slabs

A low-strength, concrete technology, applied in caissons, buildings, infrastructure engineering, etc., can solve the problems of poor concrete compactness, affecting the durability of beams and slabs, and cannot be dismantled, so as to improve the compressive strength, improve the compactness, and durability sex enhancing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

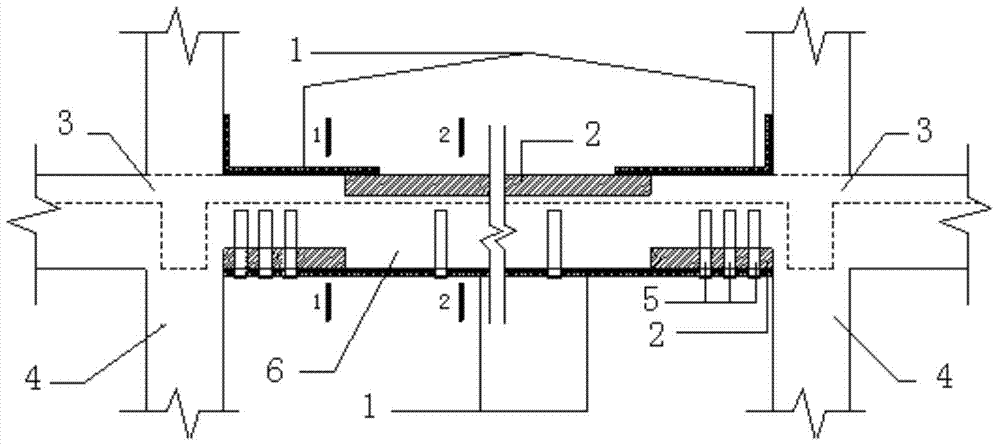

[0023] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0024] A method for reinforcing low-strength concrete beam slabs, comprising the steps of:

[0025] (1) Divide the beam and slab to be reinforced into two parts: the tension area and the compression area;

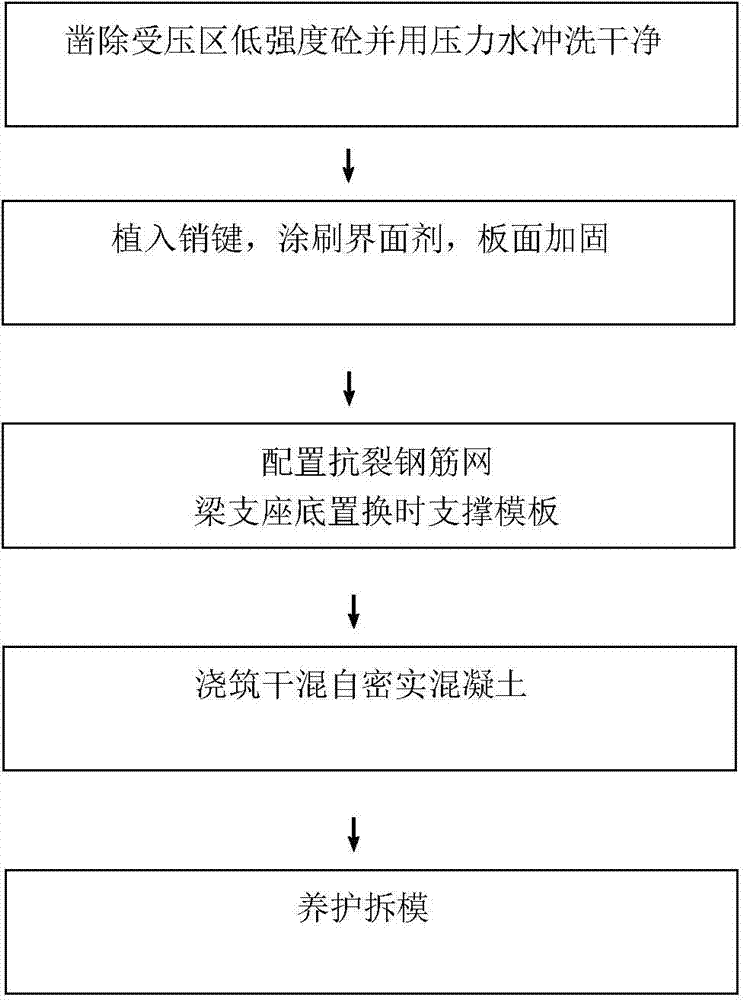

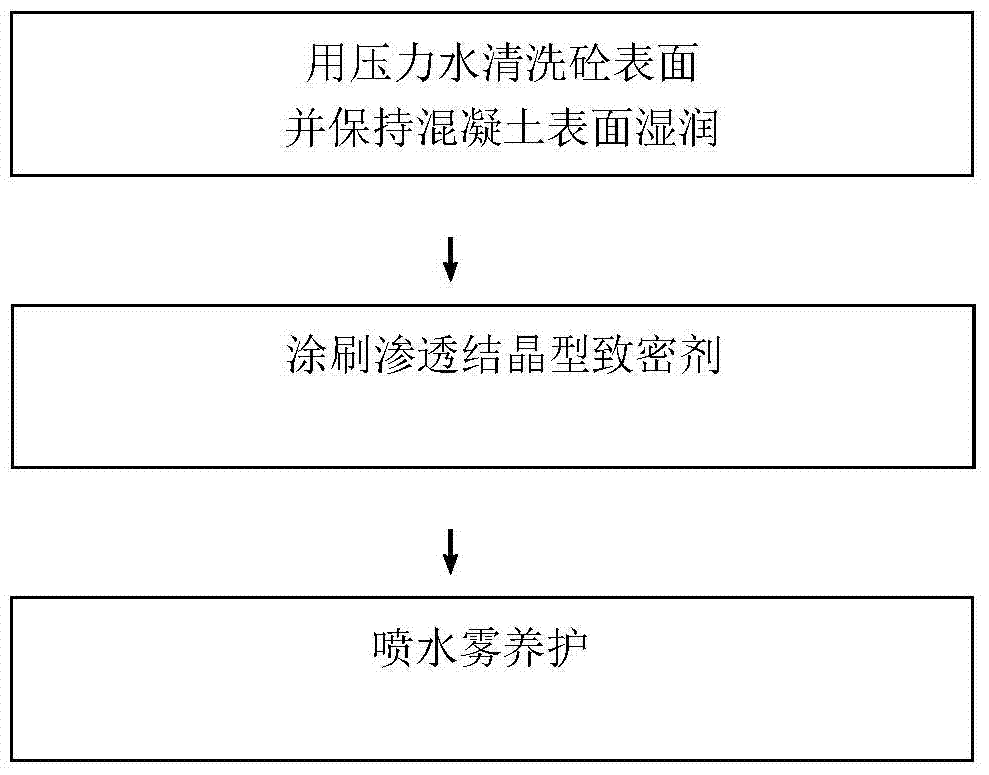

[0026] (2) Replace and reinforce the compression zone with dry-mixed self-compacting concrete, such as figure 1 As shown, the specific method is as follows: 1) Chisel out the low-strength concrete in the pressure area and rinse it with pressure water (the depth and range of chiseling are calculated and determined by a proprietary formula); 2) Insert pin keys, apply interface agent, and Reinforcement (the number of pin keys is calculated and determined by a proprietary formula); 3) Configure crack-resistant steel mesh to support the formwork when the bottom of the beam support is replaced; 4) Pouring dry-mixed self-compacting concrete (concr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com