Three-point long-stroke multi-stage trapezoidal lead screw heavy load lifting tool

A long-stroke, trapezoidal technology, applied in the direction of load hanging components, transportation and packaging, safety devices, etc., can solve the problems of large installation area, low space utilization rate, heavy equipment gross, etc., to achieve flexible movement, compact structure, and center of gravity Adjustable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described in detail below in conjunction with specific embodiments.

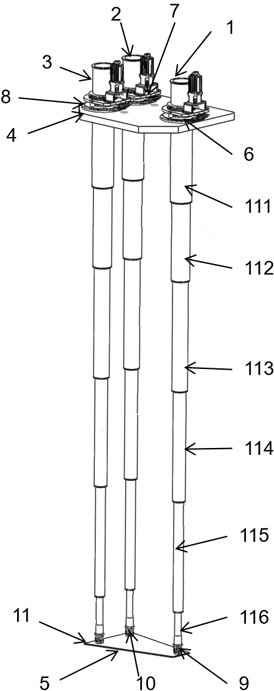

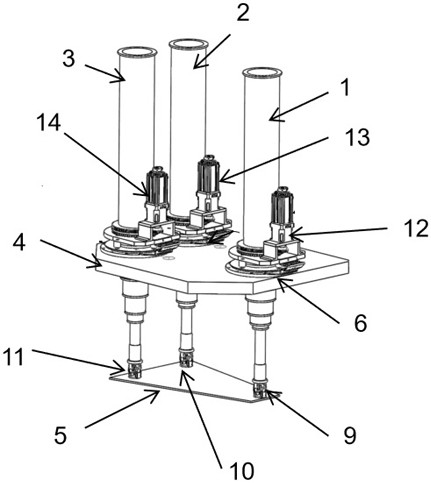

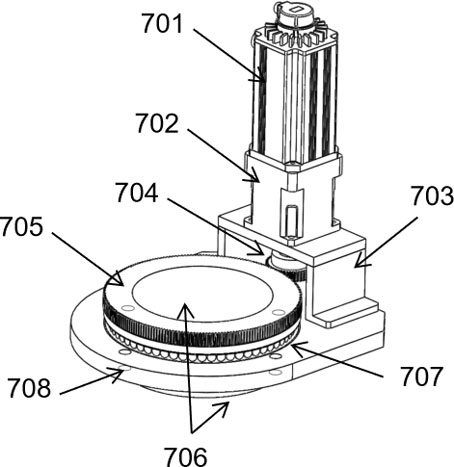

[0028] A three-point long-stroke multi-stage trapezoidal screw heavy-duty sling, including three heavy-duty long-stroke lifting multi-level trapezoidal screw, the first heavy-duty long-stroke lifting multi-level trapezoidal screw 1, the second heavy-duty long-stroke lifting Multi-stage trapezoidal screw 2 and the third heavy-duty long-stroke lifting multi-stage trapezoidal screw 3, spreader base platform 4, hoisting operation platform 5, three sets of motor drive components 12, three sets of spherical hinges 6 and three cross joint hinges 9. Each heavy-duty long-stroke lifting multi-stage trapezoidal screw is installed on the spreader base platform 4 through the motor drive assembly 12 and the spherical hinge 6, and the lifting operation platform 5 is through three joint hinges 9 and three heavy-duty long-stroke The lower end of the lifting multi-stage trapezoidal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com