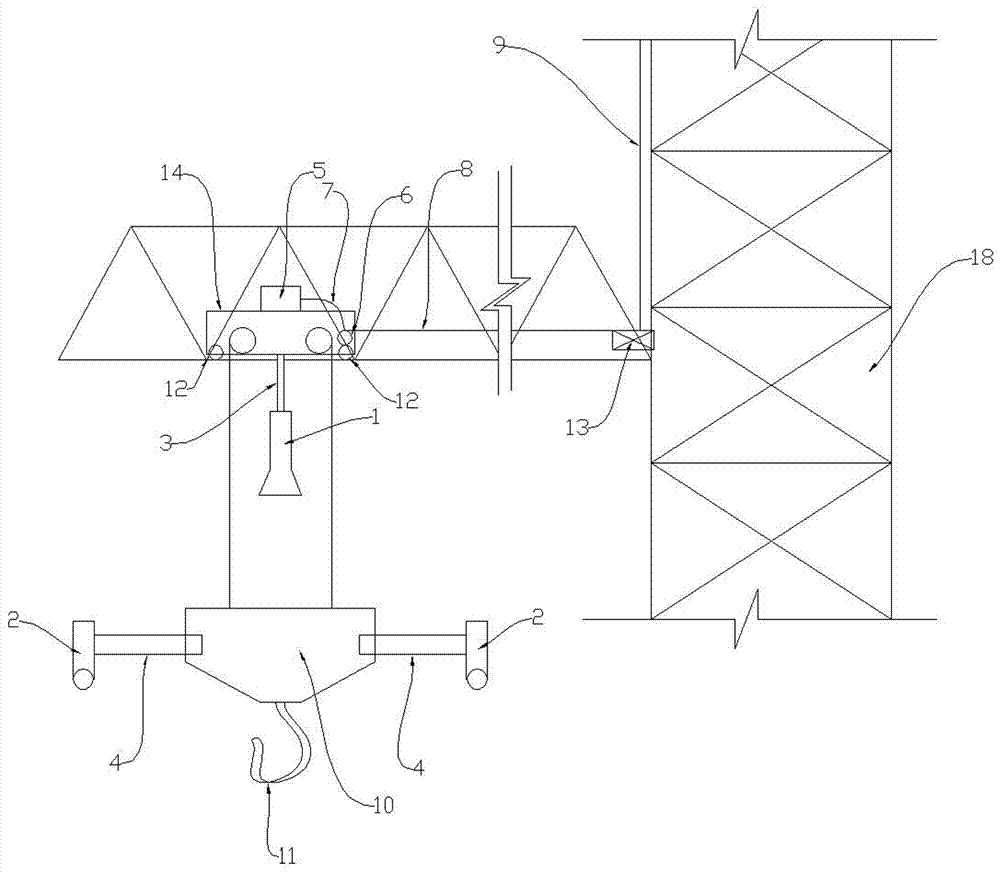

Three-function tower crane monitoring system

A monitoring system, video monitoring system technology, applied in the direction of load hanging components, safety devices, cranes, etc., can solve the problems of no tower body verticality monitoring system, no automatic search for blind spot hanging positions, no video monitoring system for tower cranes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

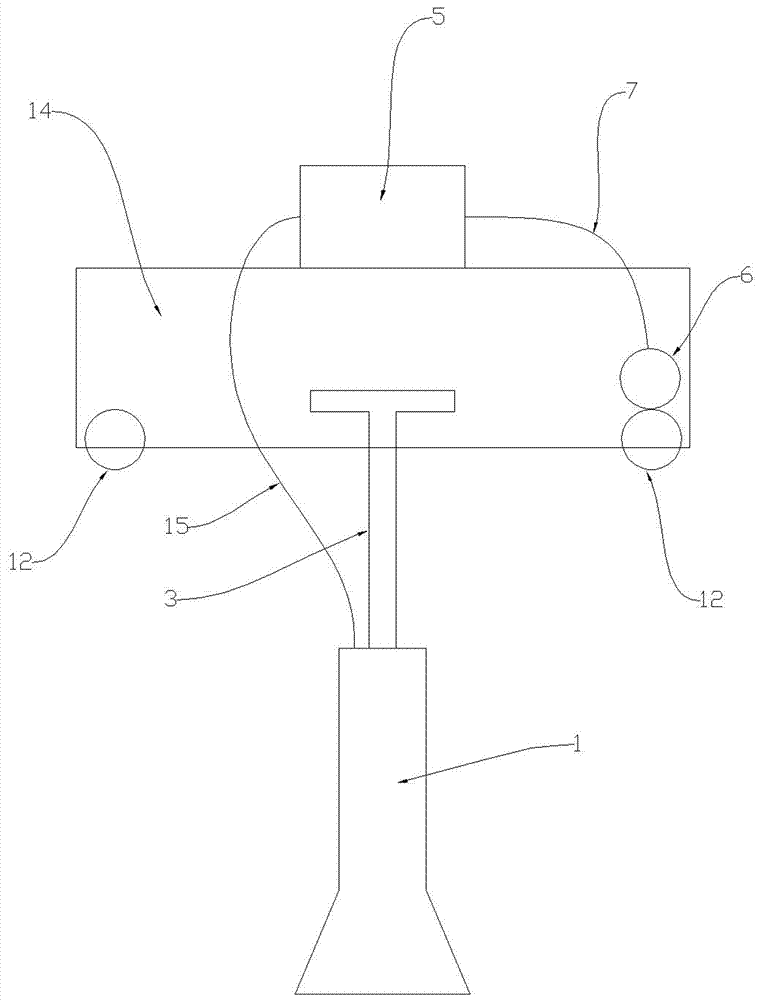

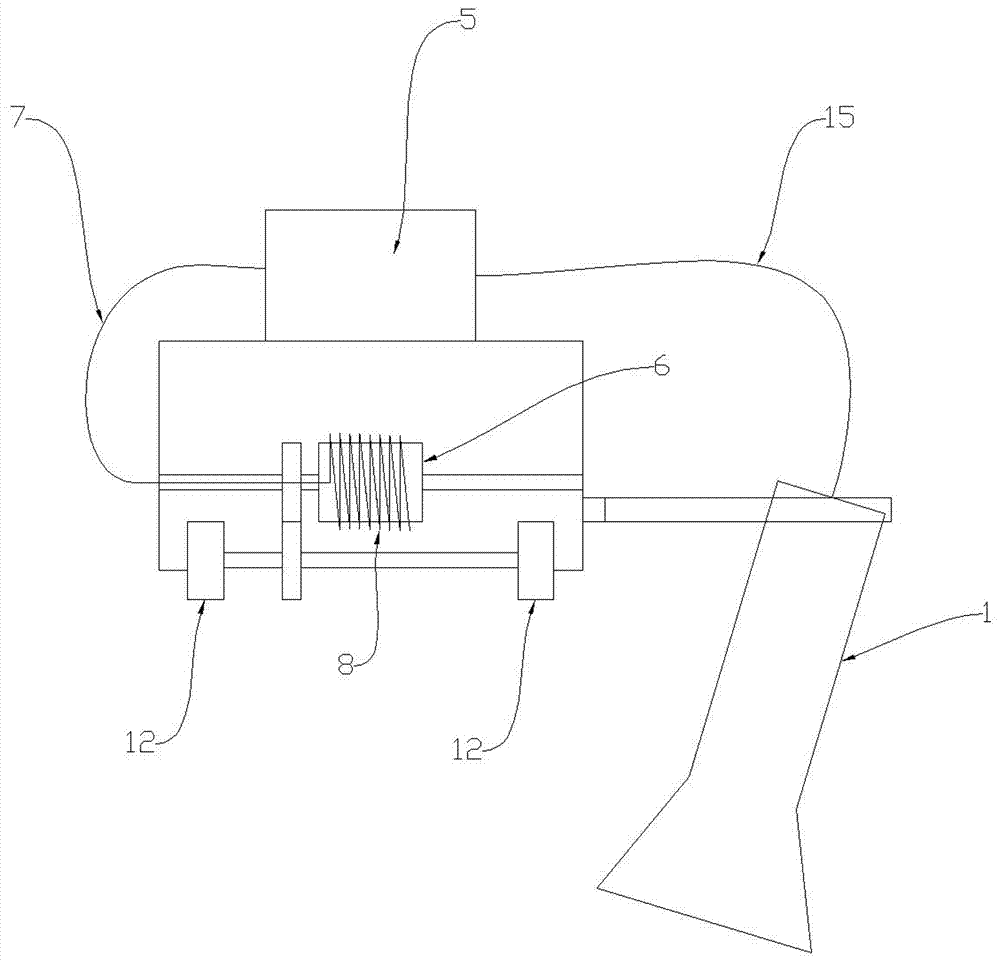

[0013] Summary of the Invention The specific implementation of the present invention has been described in detail, and will not be repeated here. It needs to be explained: camera A can automatically adjust the focus; the tower crane driver can adjust the viewing angle of camera B in the control room; The function of adjusting the viewing angle is a known technology, and will not be repeated here; the multiple steel wire bundles of the signal output line B play a tensile role, which can protect the signal line core of the signal output line B from being pulled, and the signal of the signal output line B The wire core plays the role of transmitting video signals; the winding wheel is a special wheel that can be linked with the wheel of the translation trolley; the signal output line A and the signal output line C are ordinary signal lines; the blind spot hanging position search system Control equipment can be added to automatically operate the rotating arm and translation trolley...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com