Rapid installation closure construction method for steel beam bolting closure section splice plate

A technology of splicing plates and closing sections, which is applied in the direction of bridges, bridge construction, erection/assembly of bridges, etc., can solve the problems of complexity, low work efficiency and long construction period.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

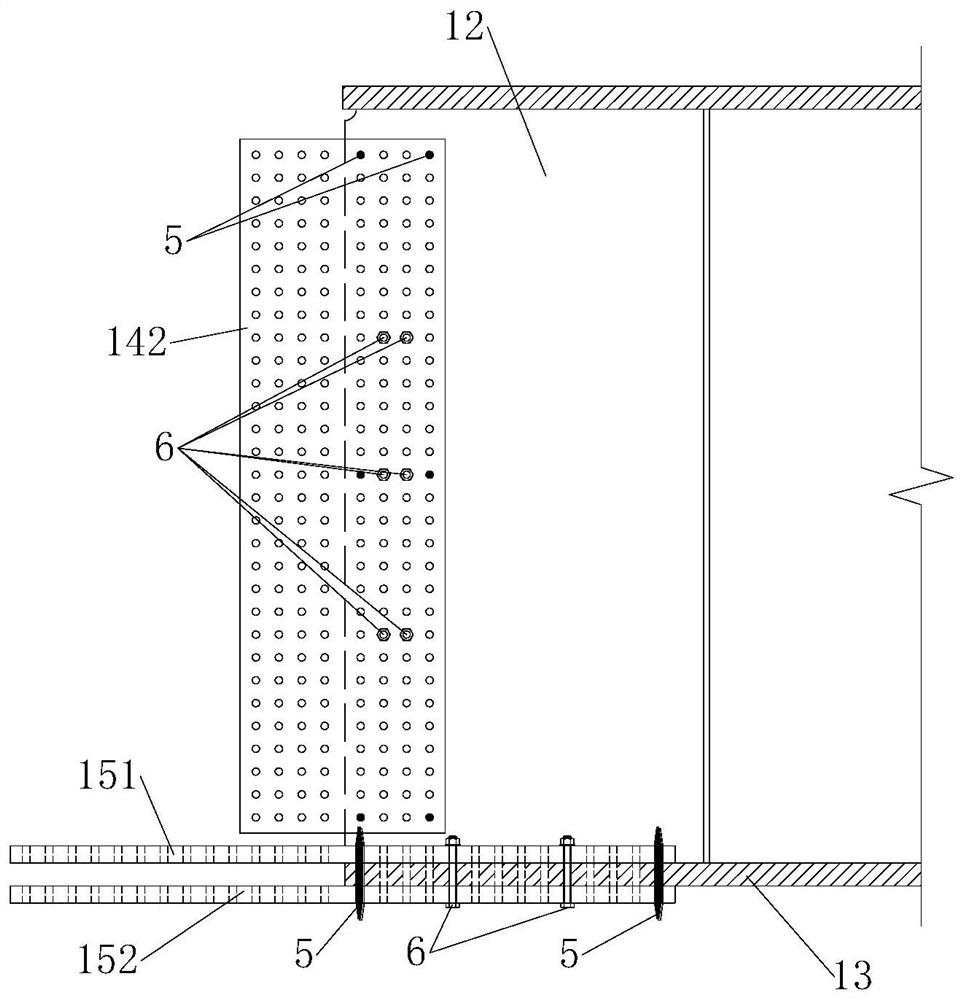

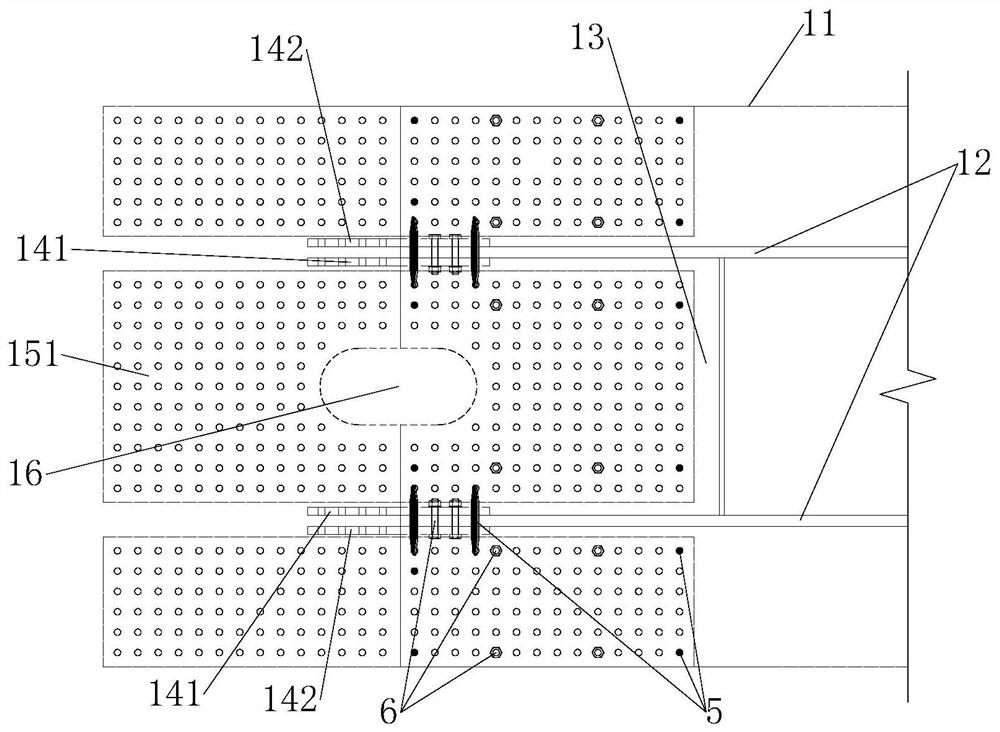

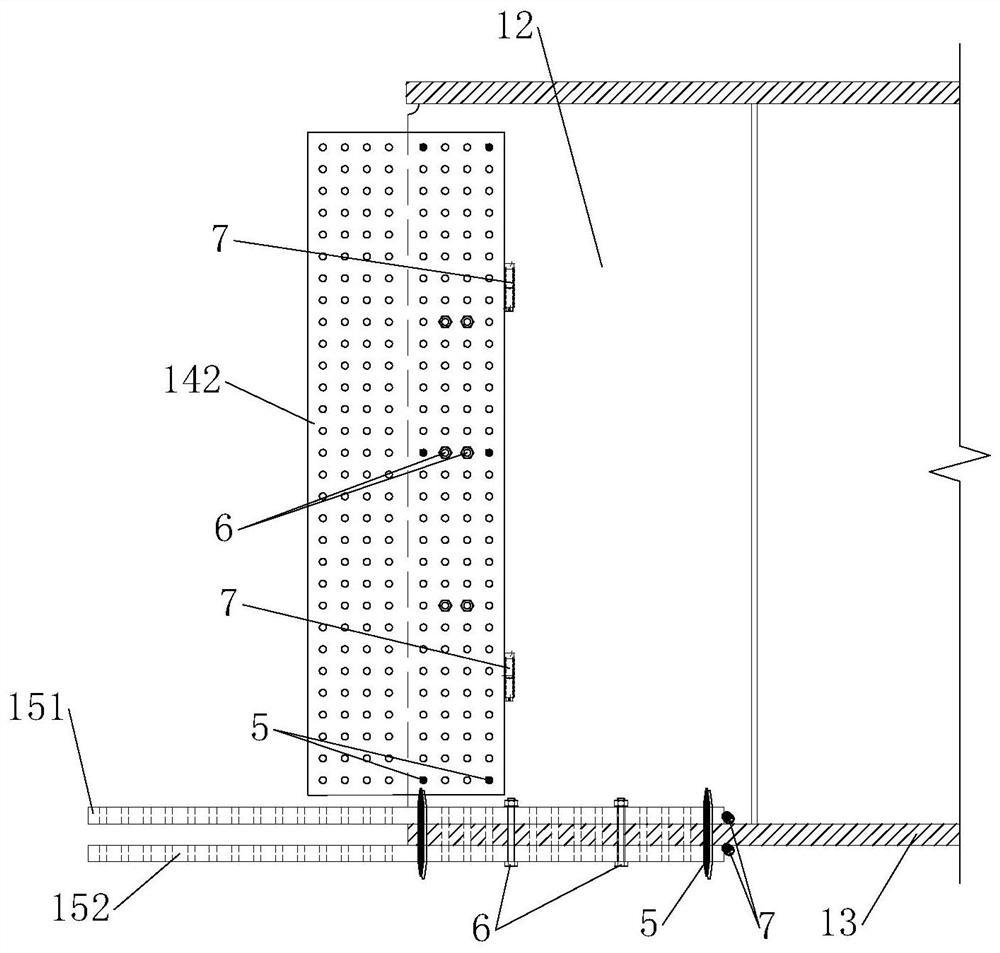

[0051] see Figure 1-9 , Figure 4-8 The arrow in the figure indicates the direction of rotation of the splicing plate. This embodiment provides a construction method for fast installation and closing of the splicing plate of the steel beam bolt joint section, including the following steps:

[0052] A. According to the design, the hinge device 7 is used to install the inner splicing plate 141 of the web on the inner side of the web-12 of the beam body 11 of the closing dragon section, and the hinge device 7 is used to install the outer splicing of the web on the outer side of the web-12 Plate 142, on the upper side of the bottom plate 13 of the closing beam body 11, the hinge device 7 is used to install the upper side splicing plate 151 of the bottom plate, and on the lower side of the bottom plate 13, the hinge device 7 is used to install the bottom splicing plate 152 of the bottom plate ;

[0053] Temporarily fix the inner splicing plate 141 of the web on the inside of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com