Special superstructure general assembly lifting lug structure

A technology of lifting lugs and lifting lugs for general assembly, which is applied to ships and other directions, and can solve problems such as large construction volume and difficult matching of wire ropes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

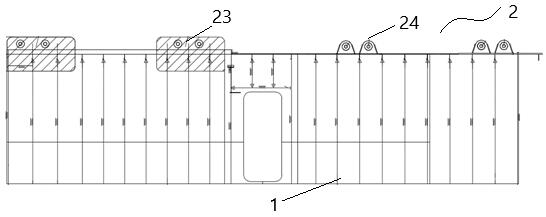

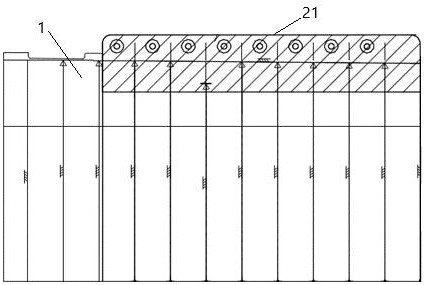

[0020] Such as Figure 1 to Figure 3 A special superstructure assembly lifting lug structure is shown, including superstructure body, bulkhead 1 and lifting lug 2, the superstructure body includes several bulkheads 1, and the lifting lug 2 is fixed on the bulkhead in sections 1 the top, the upper body can be hoisted directly through the matching steel wire rope of the lifting lug 2, so as to ensure the strength of the overall hoisting of the upper building.

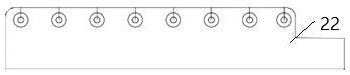

[0021] The lifting lug 2 includes a first lug 21 , a second lug 22 , a third lug 23 and a fourth lug 24 reinforced by brackets to enhance the stability and structural strength of the lug.

[0022] The first lifting lug is a first fixing surface and a first lifting joint surface vertically connected to each other to form a right-angled triangle structure, and a plurality of first lifting holes are opened on the first lifting joint surface, and between adjacent lifting holes The spacing is equal, and the first lifting lug ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com