Hydraulic adjustable hub sling for wind-driven generator

A wind turbine, adjustable technology, applied in the directions of load hanging components, transportation and packaging, can solve the problems of difficult adjustment of the hub installation position, lack of safety and reliability, complex structure of the spreader, etc., to reduce construction costs, use Safe, reliable and accurate alignment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

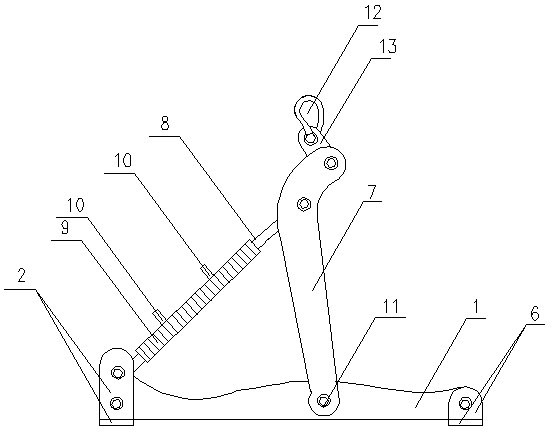

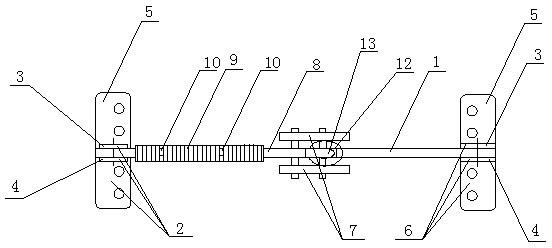

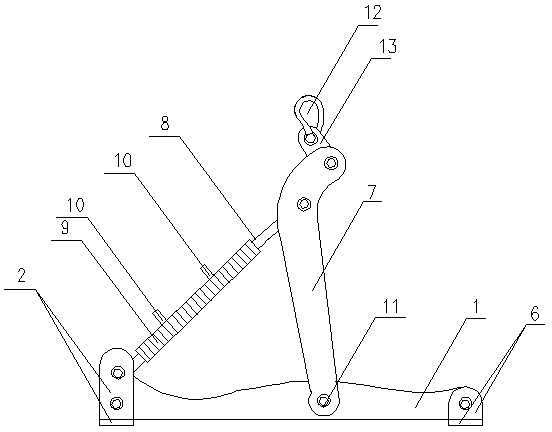

[0011] A hydraulically adjustable wind turbine hub spreader, characterized in that the hub spreader is mainly composed of a main boom 1, an adjusting arm 7, a left connecting seat plate 2, a right connecting seat plate 6, a lifting plate 13, and a shackle 12 The main boom 1 is a long strip-shaped vertical panel arranged in the left and right directions, the upper surface of the middle section is arc-shaped and convex, and the upper surfaces of the left and right ends are arc-shaped. Connecting holes are respectively set in the middle, and the connecting holes at the left end of the main boom 1 are fixed with bolts to install the left connecting seat plate 2, which is mainly composed of the bottom plate 5 and the front and rear vertical plates 4 and 3 welded together. The base plate 5 is a front-to-rear rectangular plate, and the left-right front vertical plate 4 and the rear vertical plate 3 are welded symmetrically at intervals in the middle of the base plate 5, and the bottom...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com