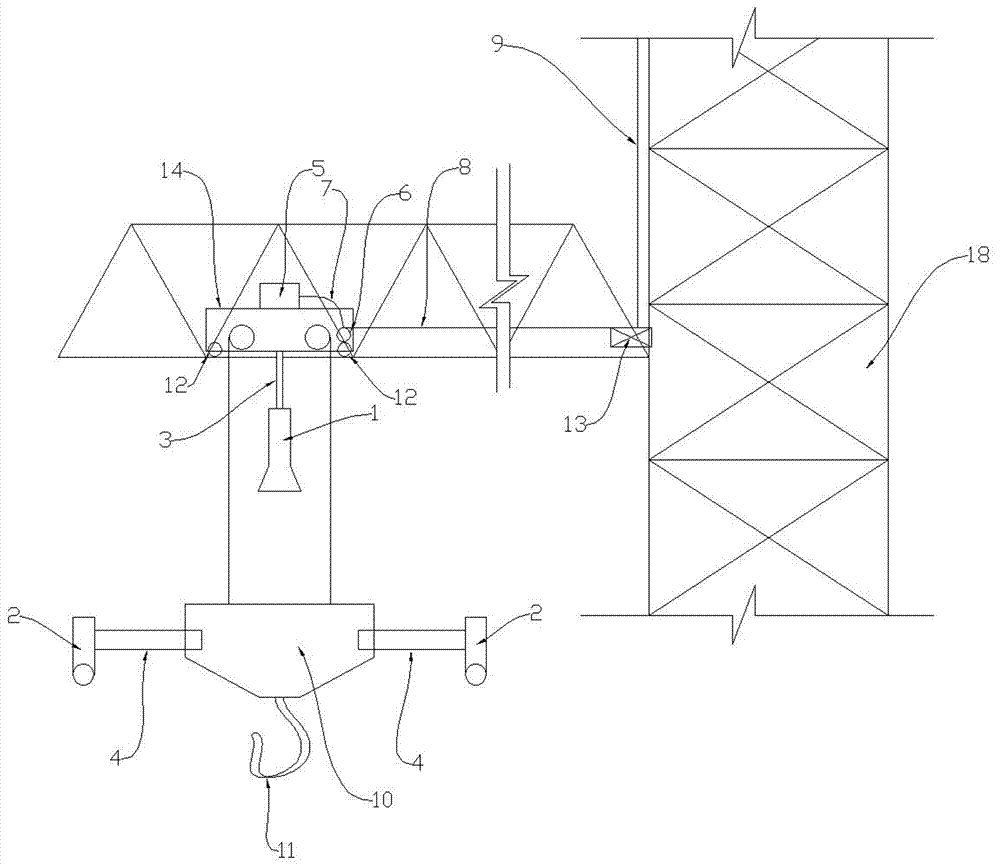

Tower crane video monitoring system

A video monitoring system and video monitoring technology, applied in the direction of load hanging components, transportation and packaging, etc., can solve the problem that the tower crane does not have a video monitoring system, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

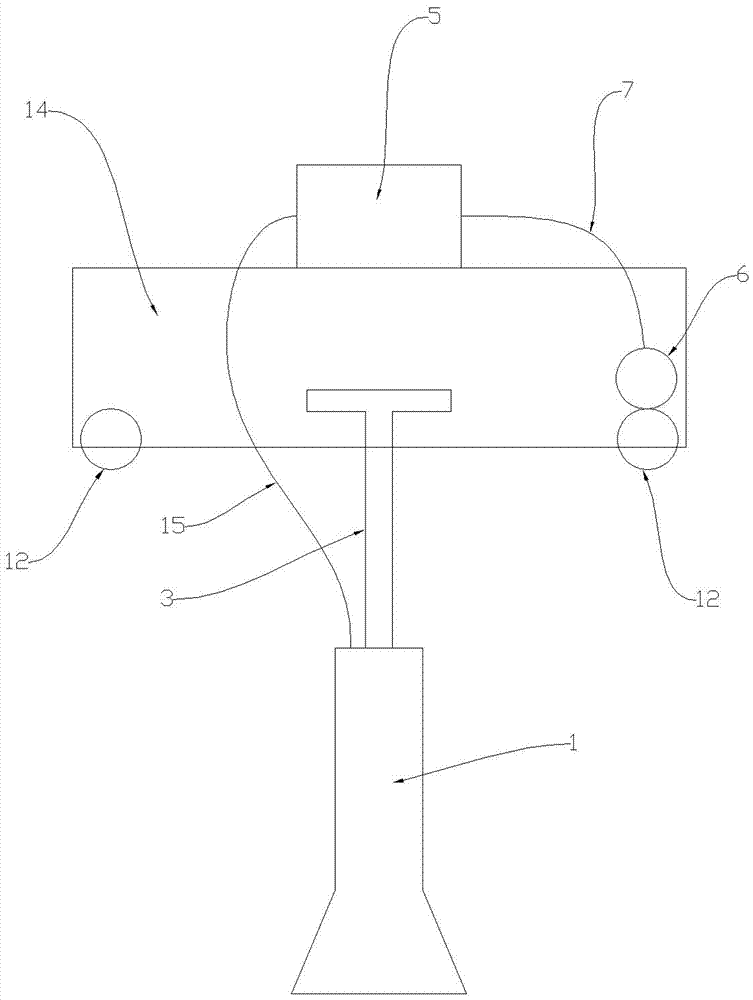

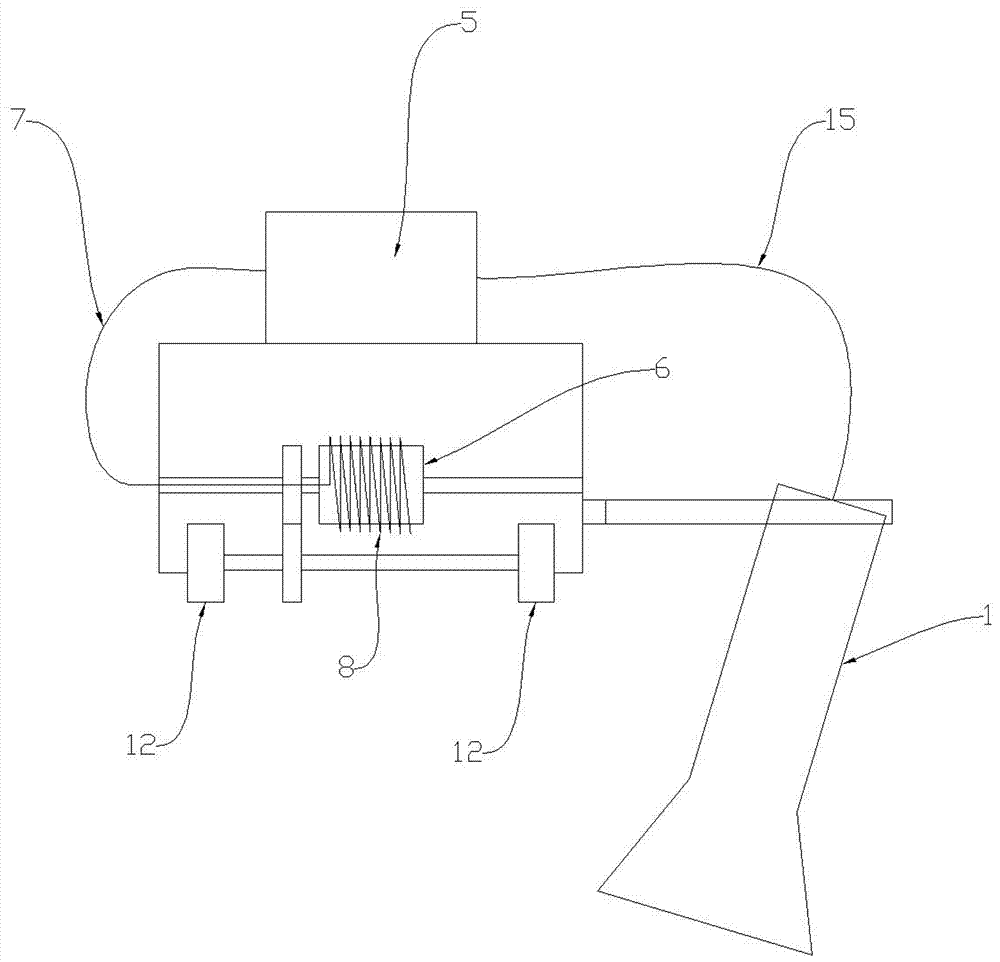

[0009] Summary of the Invention The specific implementation of the present invention has been described in detail, and will not be repeated here. It needs to be explained: camera A can automatically adjust the focus; the tower crane driver can adjust the viewing angle of camera B in the control room; The function of adjusting the viewing angle is a known technology, and will not be repeated here; the multiple steel wire bundles of the signal output line B play a tensile role, which can protect the signal line core of the signal output line B from being pulled, and the signal of the signal output line B The wire core plays the role of transmitting video signals; the winding wheel is a special wheel that can be linked with the wheel of the translation trolley; the signal output line A and the signal output line C are ordinary signal lines.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com