Automatic bag folding and integrated packaging system

A stacking and assembly technology, which is applied in the direction of transportation, packaging, and stacking of objects, can solve the problems of reducing the number of labor, and achieve the effects of avoiding friction, ensuring hoisting safety, and improving hoisting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

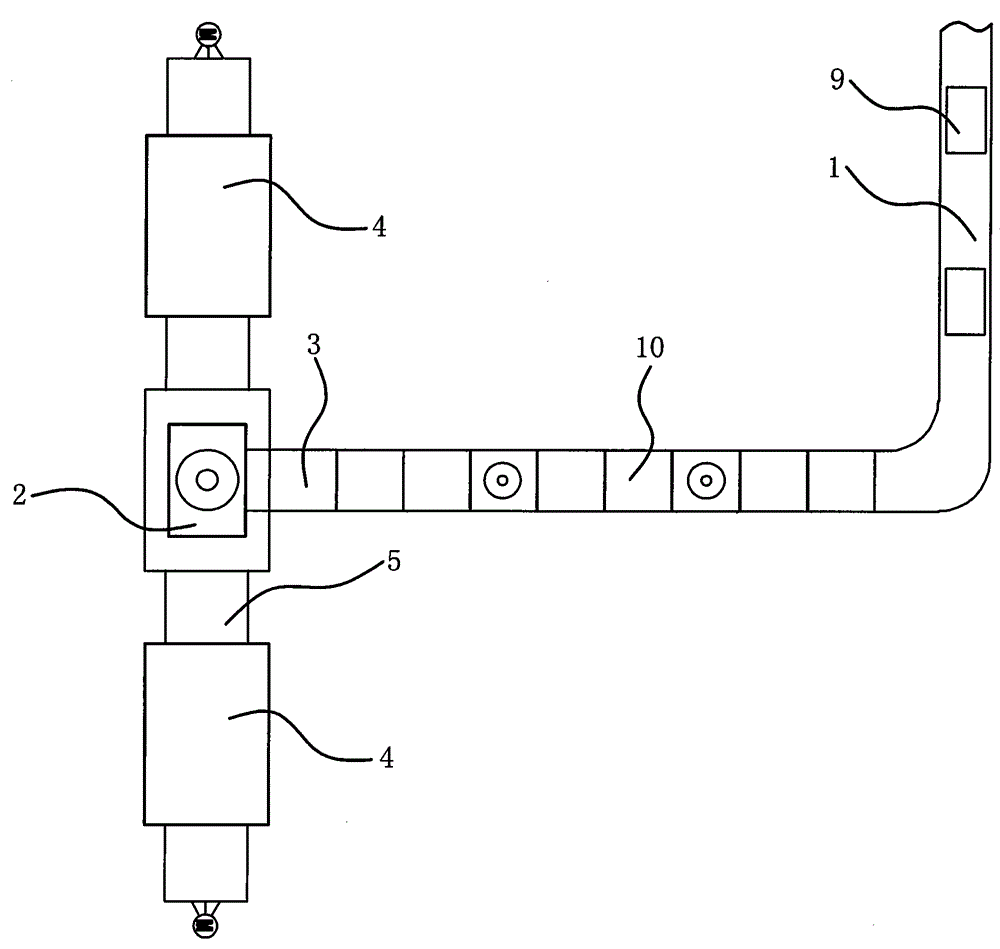

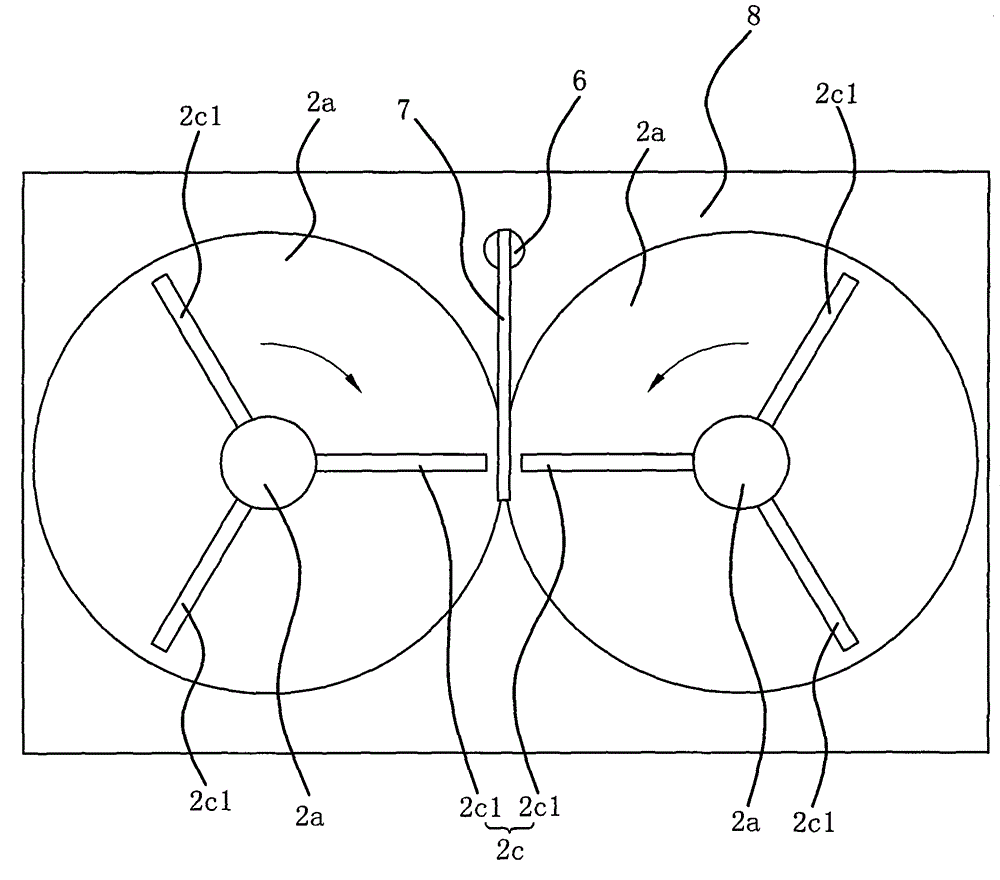

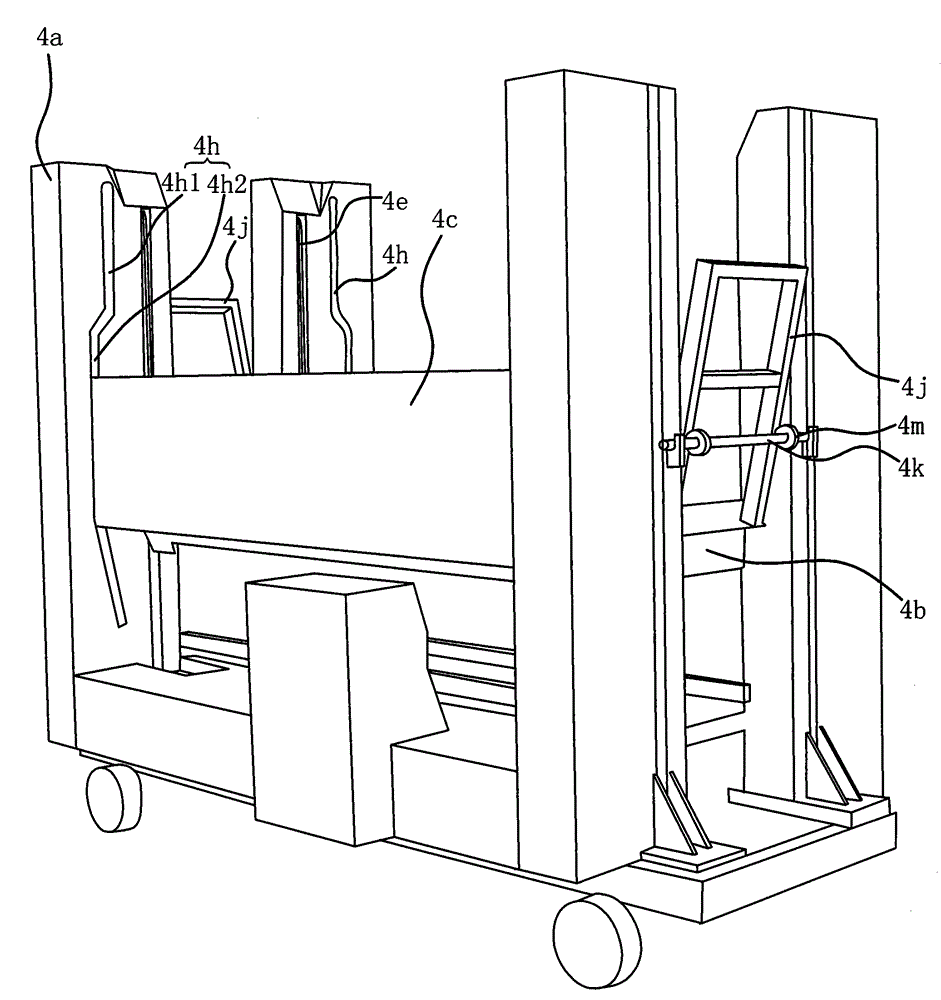

[0026] Such as figure 1 As shown, the automatic stacking and packaging system includes a frame 8, a roller conveyor line 1, a drop control device 2, a high-speed conveyor line 3, a stacking trolley 4 and a trolley guide rail 5.

[0027] The roller conveying line 1 is horizontally arranged on the frame 8. There are multiple drive motors in the roller conveying line 1. By controlling the driving motors to adjust the rotating speed of the rollers, automatic adjustment of the posture of the bags 9 and automatic adjustment of the distance between two adjacent bags 9 are realized. Spacing, bag 9 spacing meets drop control requirements.

[0028] Such as figure 1 and Figure 6 As shown, the high-speed conveying line 3 and the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com