Construction method of reinforced concrete box girder

A construction method and technology of steel box girder, applied in the direction of bridges, bridge construction, erection/assembly of bridges, etc., can solve the problems affecting the opening plan, the tight construction period of Daxing Airport, etc., and achieve close contact between the top surface of the scaffold and the bottom surface of the flange plate, The effect of reducing material input and increasing safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

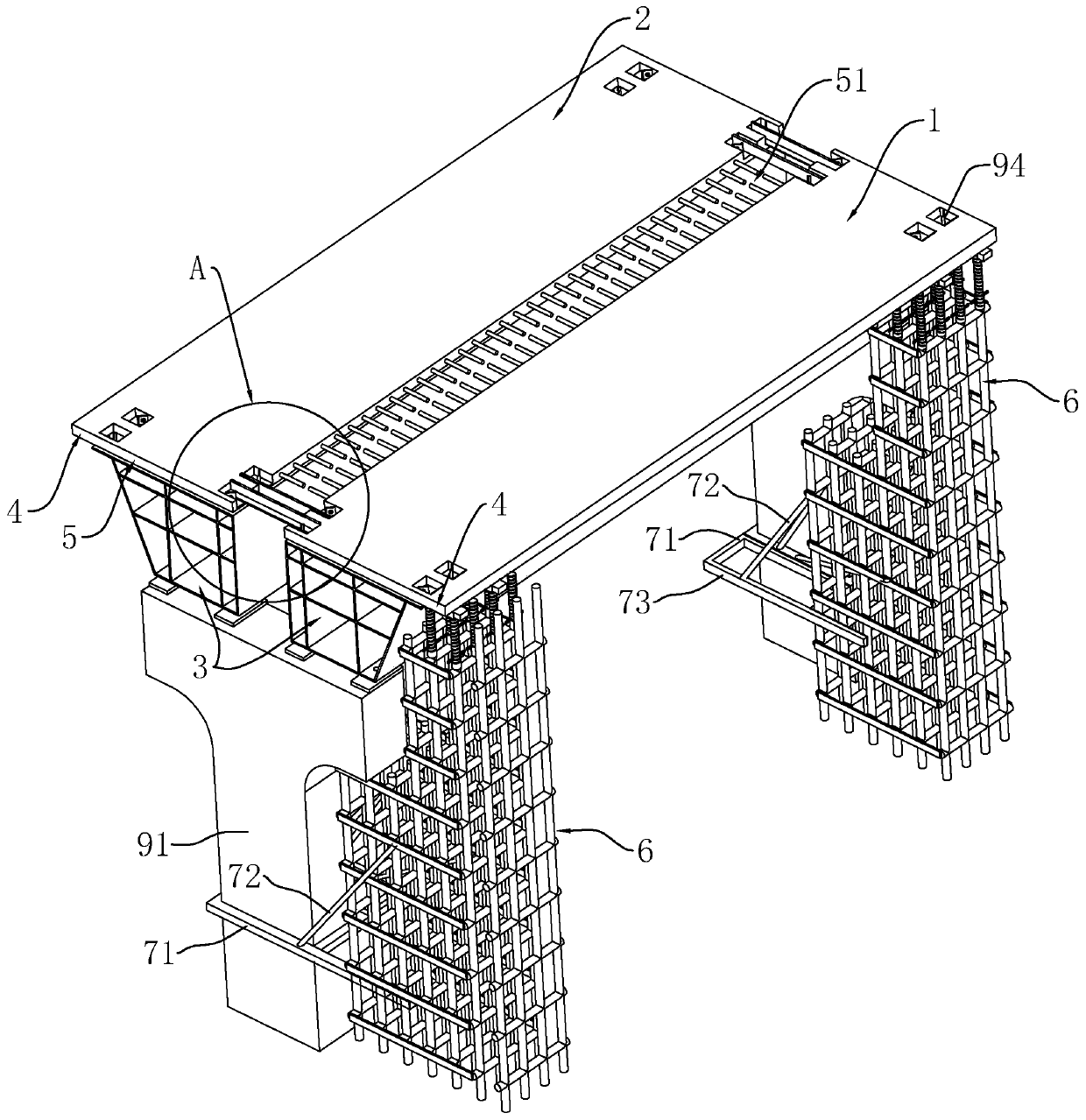

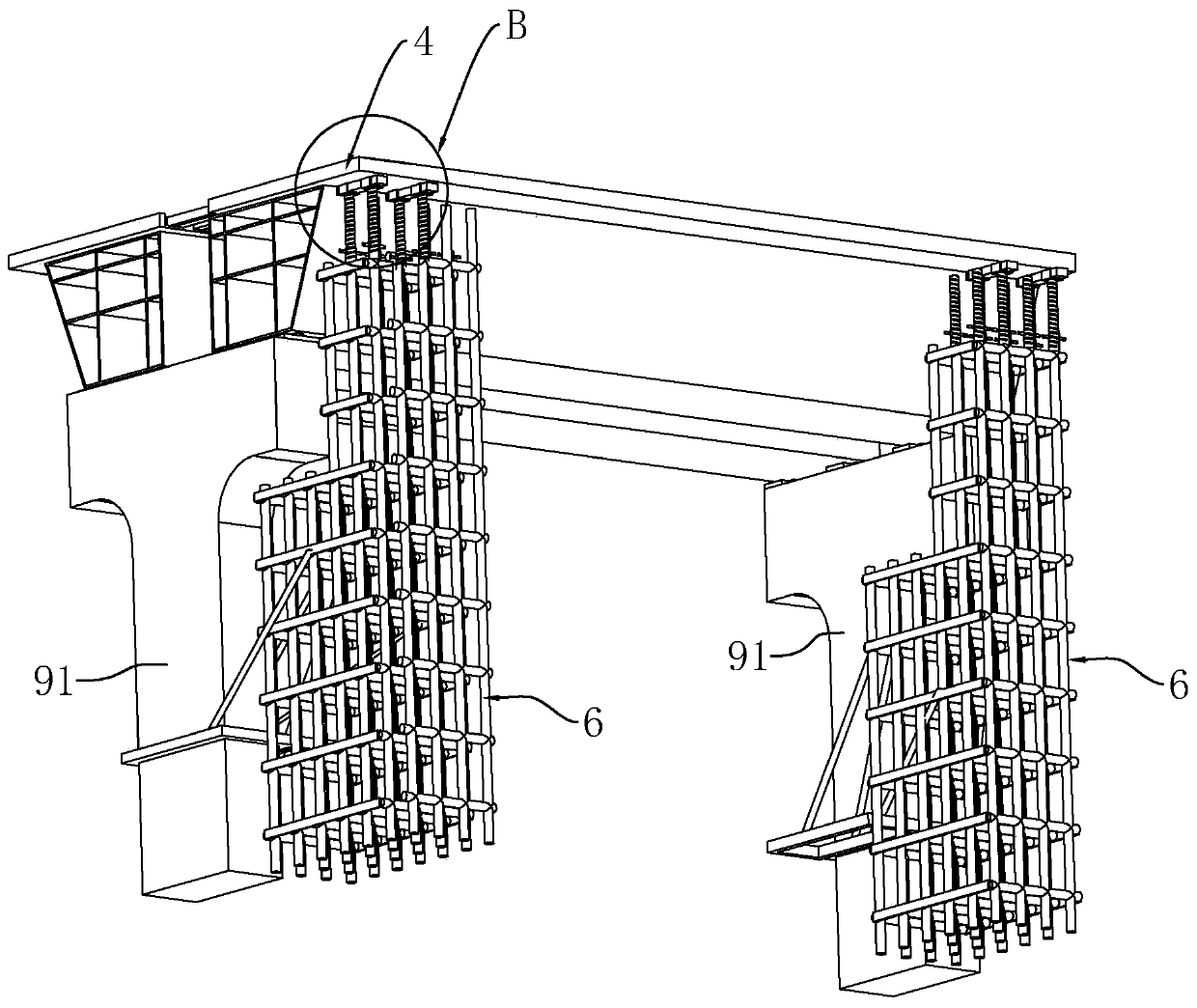

[0037] Embodiment 1: This embodiment is described with the construction of lead wires at Daxing Airport: refer to figure 2 , the one-span steel-concrete box girder connected to the swivel girder includes two steel-concrete box girders arranged in parallel, namely the first steel-concrete box girder 1 and the second steel-concrete box girder 2, and the space between the two steel-concrete box girders A post-casting belt 51 is provided; each piece of steel-concrete box girder includes a steel box girder body 3 , a concrete bridge deck 5 and a flange plate 4 .

[0038] A construction method for a steel-concrete box girder disclosed by the present invention comprises the following construction steps:

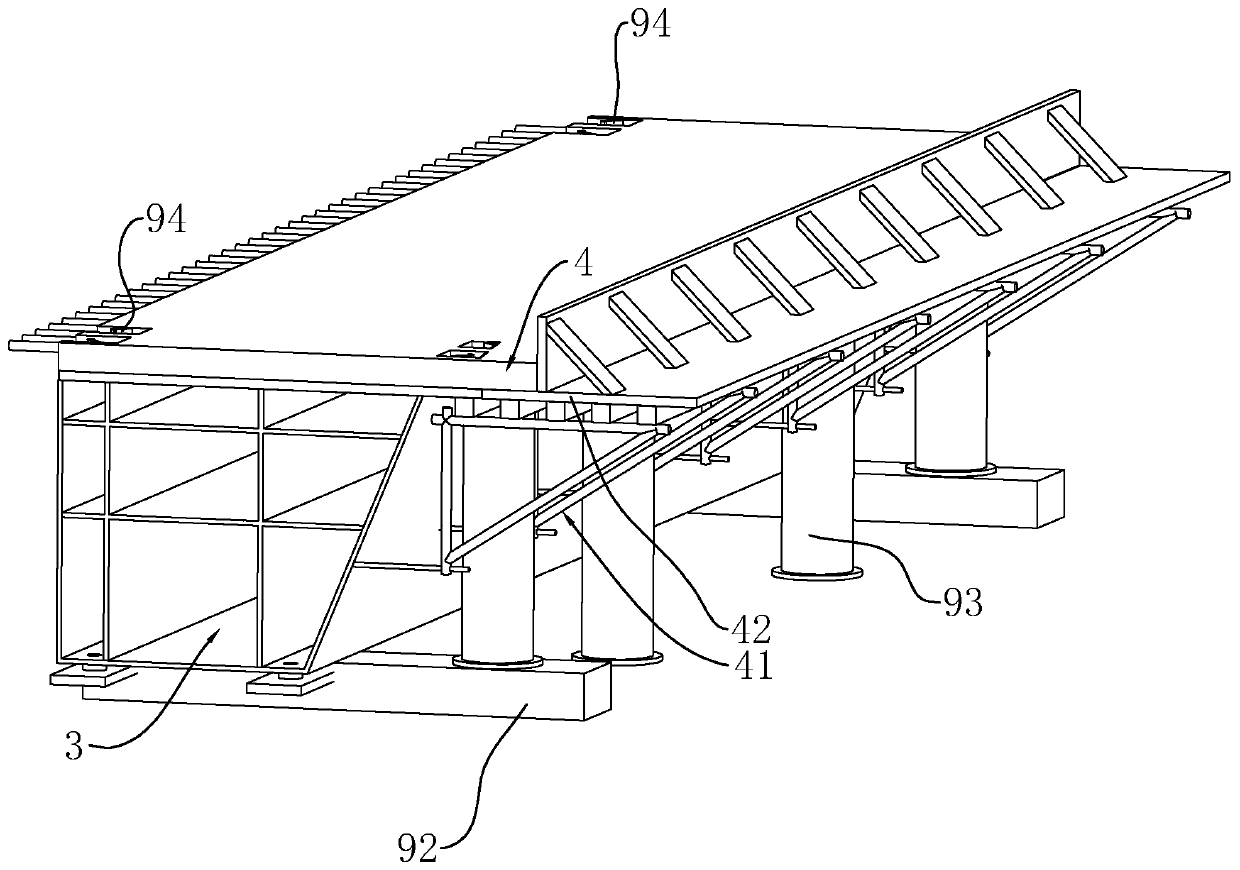

[0039] Step 1: If figure 1 As shown, a strip concrete base 92 is constructed on the ground near the position where the beam body is to be installed, and a plurality of vertical steel pipe supports 93 are installed on the side of the base 92, and then two steel box girder bodies 3 ...

Embodiment 2

[0052] When all the bridges are steel-concrete box girders, the steel-concrete box girders of all spans can be constructed on the ground for the bridge deck and flange plates, and then hoisted as a whole. Before hoisting, it is enough to set the scaffolding unit for support on the same side of the pier.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com