Bundled steel tube lifting appliance

A technology of binding steel pipes and spreaders, which is applied in the direction of load hanging components, transportation and packaging, etc., which can solve the problems of personnel injury and low steel pipe handling efficiency, and achieve the effects of reducing labor costs, shortening hoisting time, and ensuring hoisting safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] In order to more fully explain the implementation of the present invention, implementation examples of the present invention are provided. These implementation examples are only illustrations of the device and do not limit the scope of the present invention.

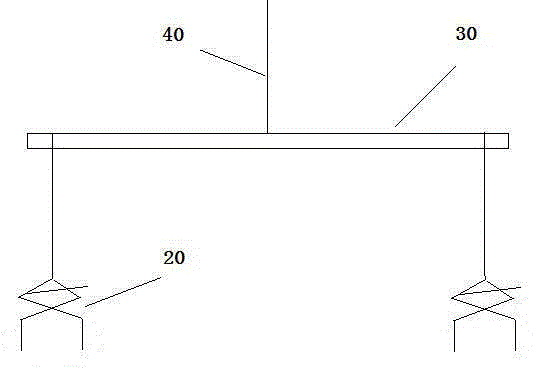

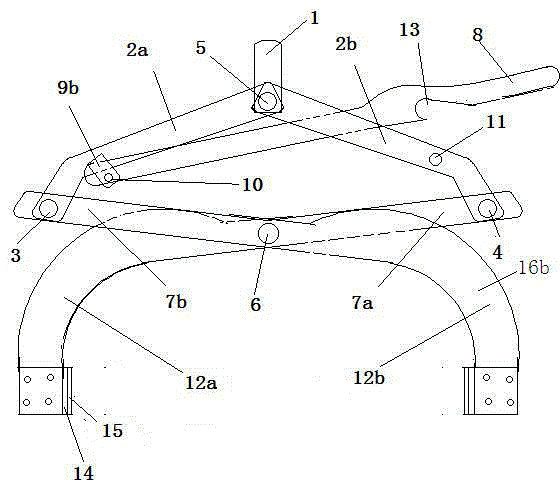

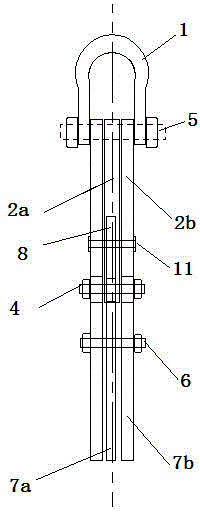

[0010] Refer to the following figure 1 and image 3 The technical solution of the present invention is further described in detail. In the figure, 1: lifting ring, 2a: upper left rhombus side, 2b: upper right rhombus side, 3: left hinge shaft, 4: right hinge shaft, 5: upper hinge shaft , 6: lower hinge shaft, 7a: lower right diamond side, 7b: lower left rhombus side, 8: locking lever, 9b: fixing piece, 10: locking hinge shaft, 11: locking pin, 12a: left hanging clip Claw, 12b: right hanging jaw, 13: locking gap, 14: clamping block, 15: friction block, 16b: L-shaped structure frame, 20: hanging claw mechanism, 30: beam, 40: hanging rope.

[0011] For ease of understanding, among the Arabic numeral codes used in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com