F-shaped standard frame for assembly and disassembly of prefabricated beam formwork and construction method

A technology of prefabricated beams and formwork, applied in the fields of formwork/formwork/work frame, on-site preparation of building components, construction, etc. problems, to achieve the effect of reducing construction costs, increasing service life and frequency, and improving construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

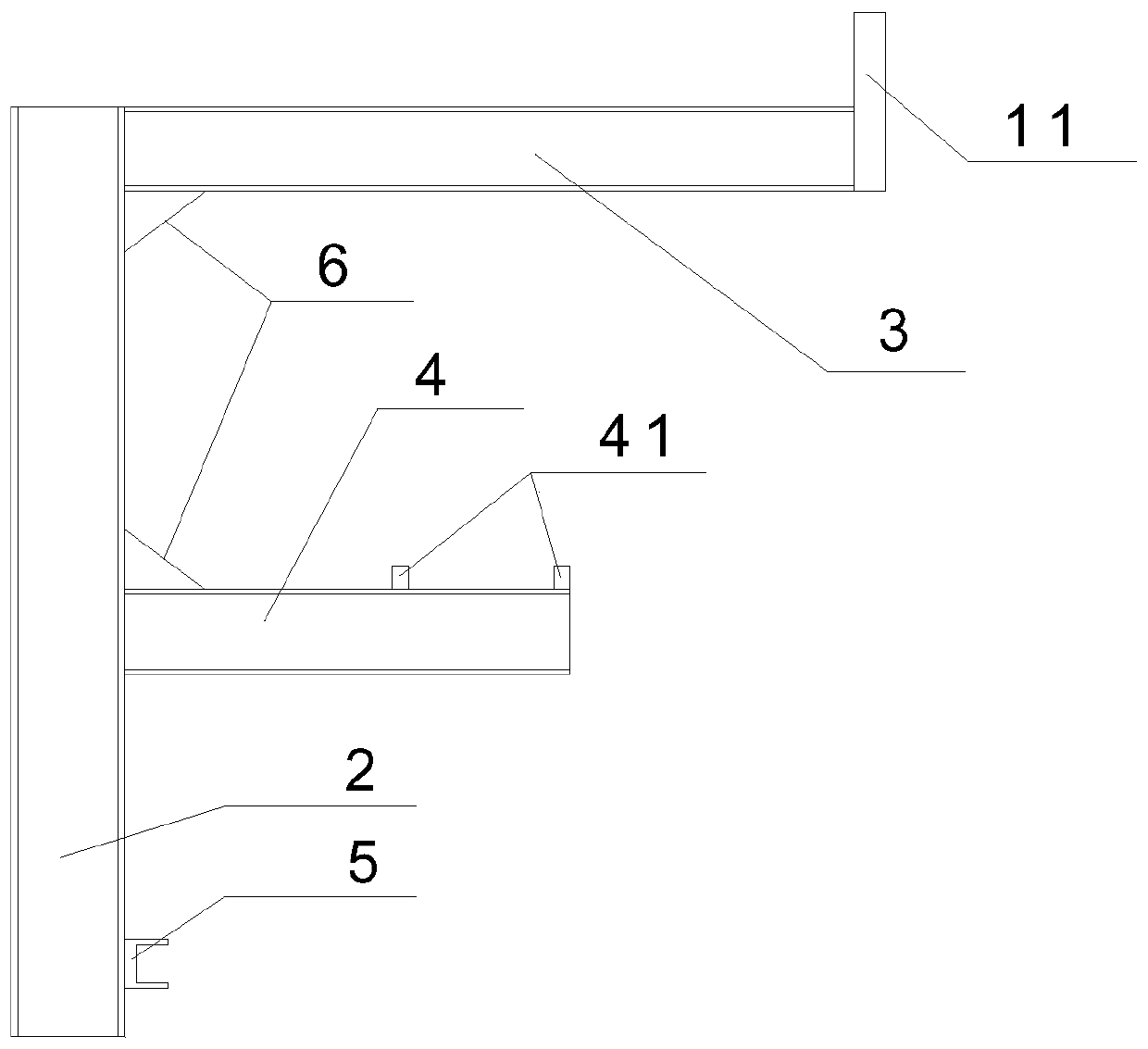

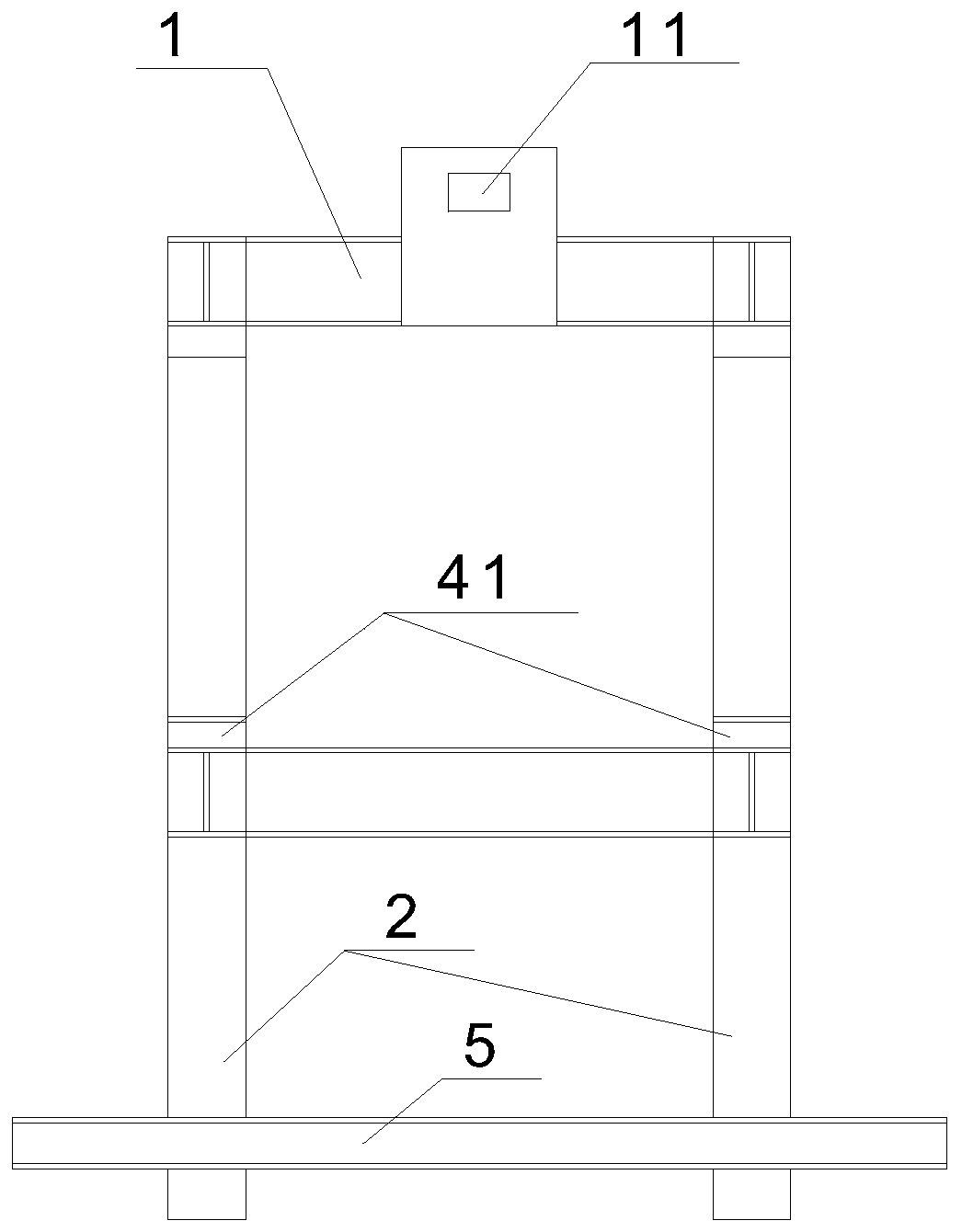

[0025] Such as Figure 1 to Figure 2 As shown, an F-shaped standard frame for installing and disassembling prefabricated beam formwork includes two F-shaped support frames arranged in parallel and a connecting rib 1 for fixedly connecting the two F-shaped support frames. Each F-shaped support frame Both include vertical ribs 2, the top right side of each vertical rib 2 is fixedly connected with a boom 3, the middle right side of each vertical rib 2 is fixedly connected with a support arm 4, and the upper surface of the support arm 4 The upper part is fixedly connected with a corner 41 which engages with the outer transverse rib of the prefabricated beam formwork, and the bottom right side of the two vertical ribs 2 is jointly fixedly connected with a back brace 5 . There are four connecting ribs 1, of which two connecting ribs 1 are respectively arranged at the top side end and the middle part of the two vertical ribs 2, and the other two connecting ribs 1 are respectively arr...

Embodiment 2

[0032] A construction method for an F-type standard frame used to assemble and disassemble a prefabricated beam formwork, comprising the following steps:

[0033] Step 1. Use the hook of the gantry crane to hook the lifting lug 11, and hang the F-shaped standard frame to the outside of the prefabricated beam formwork;

[0034] Step 2, two F-shaped support frames are clamped between two adjacent longitudinal ribs on the outside of the prefabricated beam formwork, and the two vertical ribs 2 are closely attached to the outer wall of the prefabricated beam formwork;

[0035] Step 3. Slowly control the gantry crane to lift, so that the clamping angle 41 on the support arm 4 is closely engaged with the outer transverse rib of the prefabricated beam formwork;

[0036] Step 4. Continue to slowly control the gantry crane to lift, and use the self-gravity of the prefabricated beam formwork to engage the back support 5 with the formwork below the prefabricated beam, so as to ensure that...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com