Dual-purpose multi-channel hydraulic proportional valve

A proportional valve, hydraulic technology, applied in the direction of fluid pressure actuation device, servo motor assembly, mechanical equipment, etc., can solve the problems of easy breakage of adjustment screws, inconvenient adjustment of adjustment screws, oil leakage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0063] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

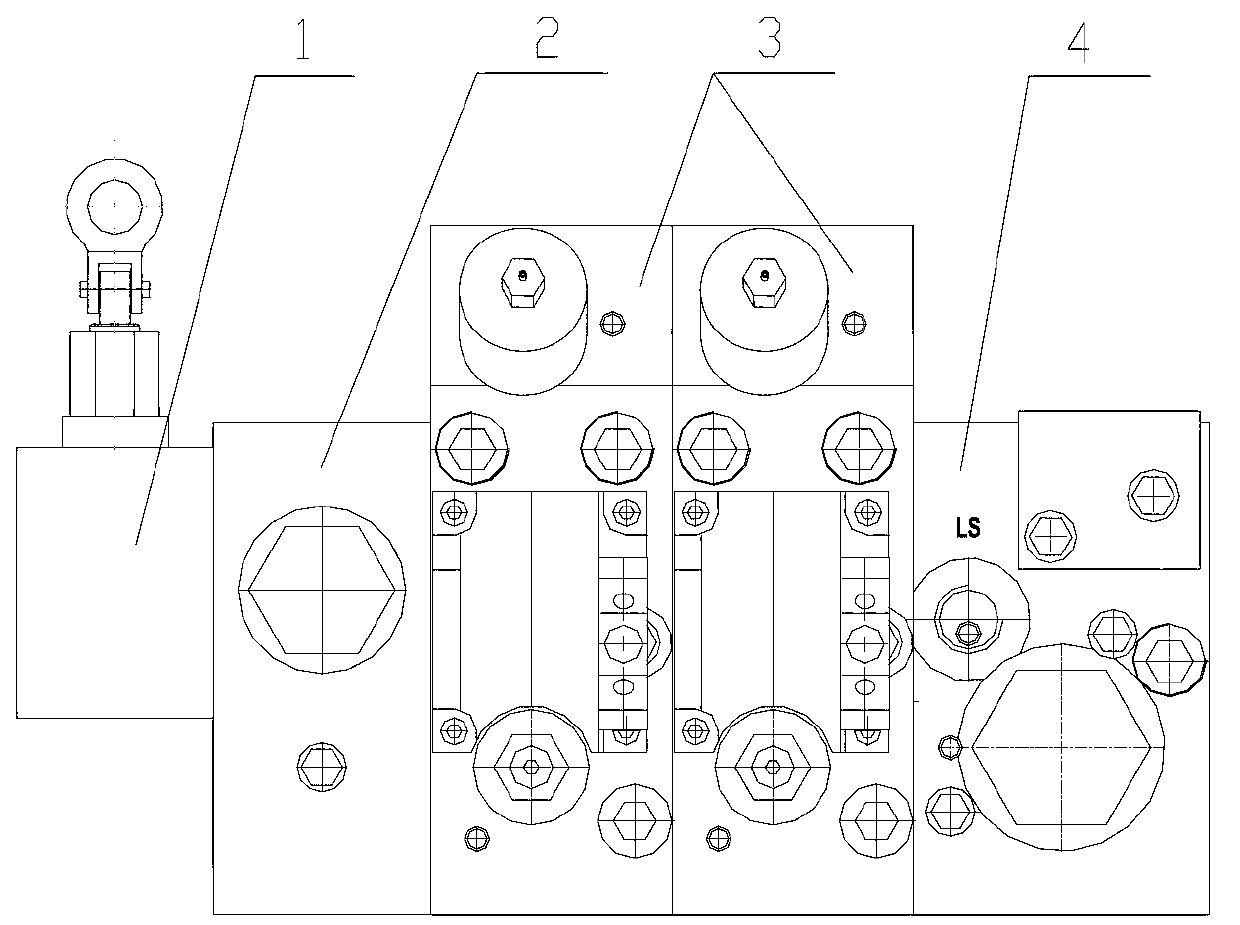

[0064] See figure 1 , a dual-purpose multi-channel hydraulic proportional valve, including a pump module 4, an executive module 3, and a tail-link module 2 connected to a manual pump module 1 and an executive module 3 on both sides, the executive module 3 is connected to the pump module 4, and connected to The pump module 4 is connected to the pump, which can be connected to a quantitative pump or a variable pump. A self-test oil circuit is arranged between the pump module 4 and the execution module 3 .

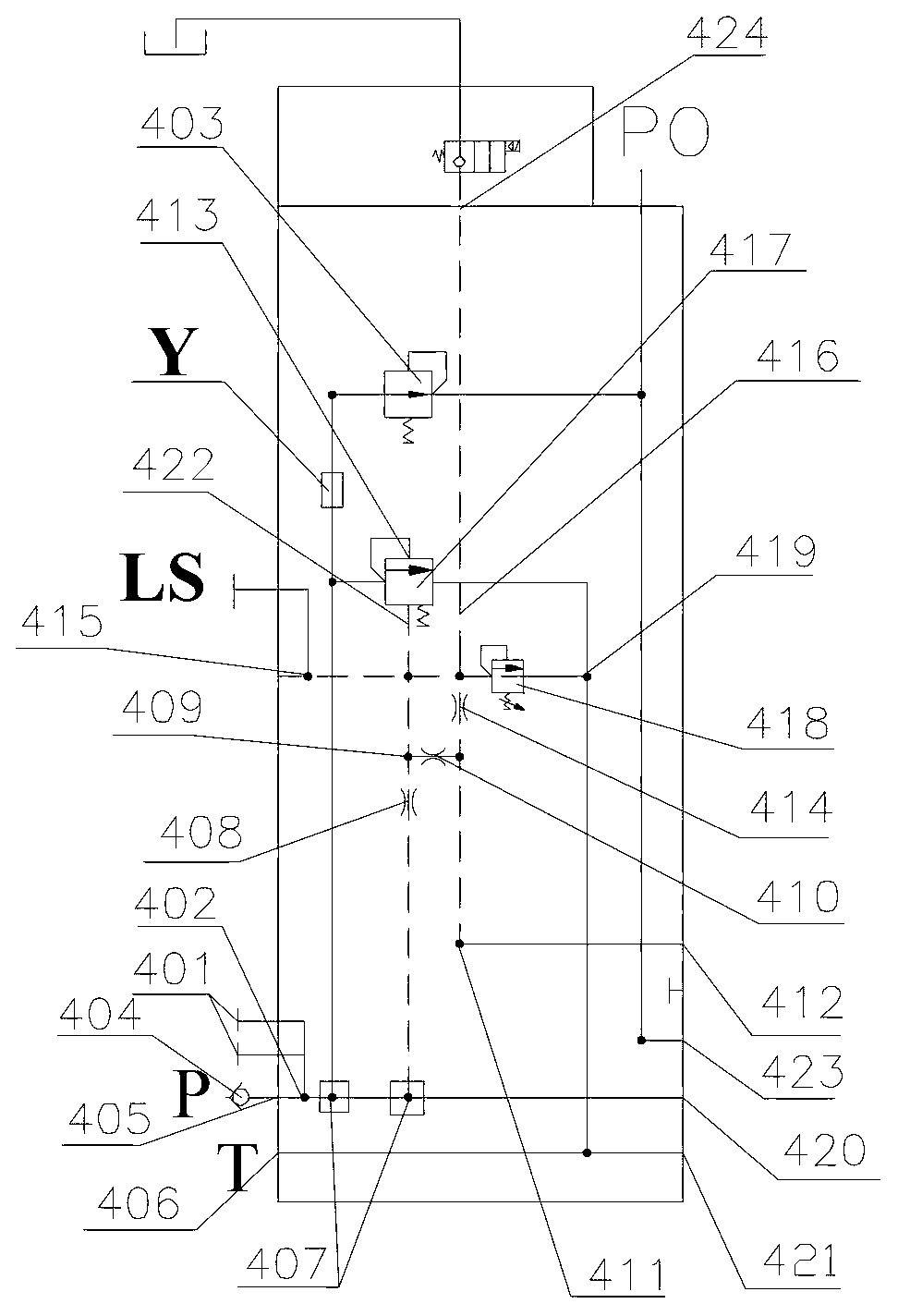

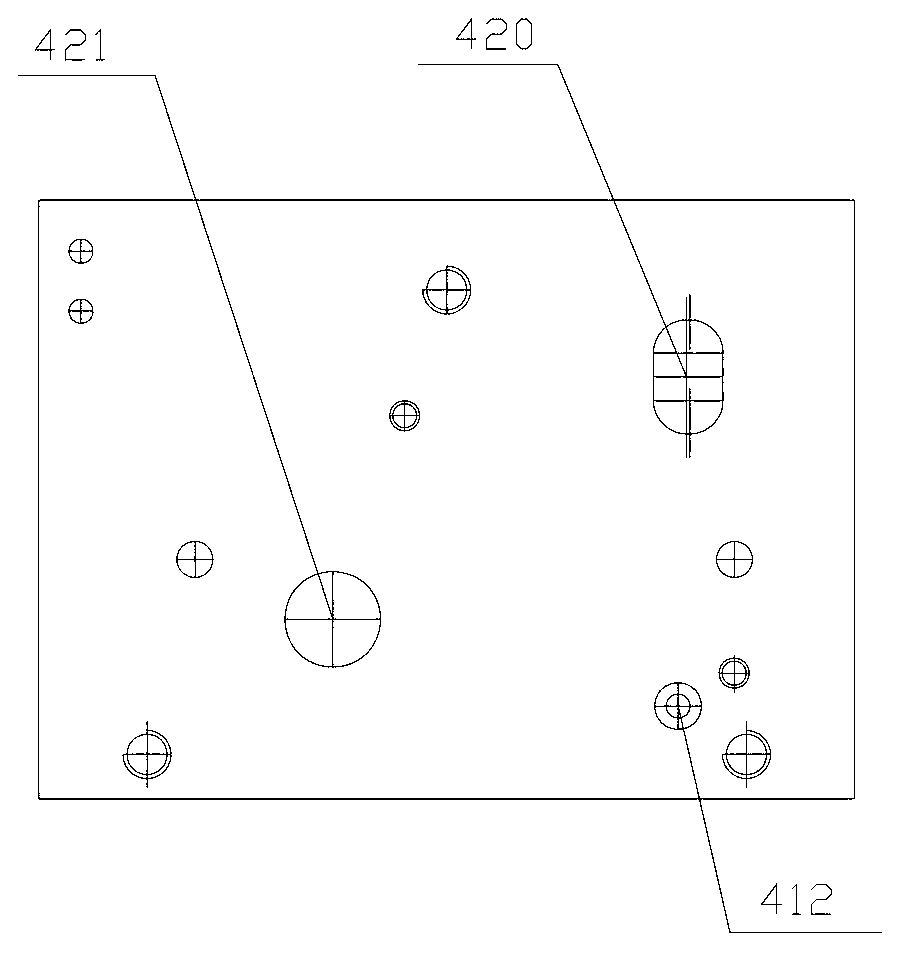

[0065] see Figure 2 to Figure 8 The pump module 4 mainly includes a one-way valve 404 connected through the internal oil circuit of the pump module, a valve body of the pump module, a three-way relief valve 417 and a pilot relief valve 41...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com